Tag Archives: Shaker Screen supplier

Shale Shaker: The Core of the Drilling Fluid Solids Control

The drilling fluid solids control process is a staged purification system. Its goal is to remove solids of varying sizes through coordinated equipment, restoring fluid viscosity and density for recycling thereby cutting costs and environmental impact. Arranged by particle size, the process begins with the shale shaker as the “first gate” of solids control.

- Front End – Shale Shaker: Fluid returning from downhole, carrying solids >74 µm, enters the shaker. High‑frequency vibration separates and discharges large cuttings, removing over 80% of solids and greatly reducing the load on downstream equipment.

- Mid Stage – Desander + Desilter: Fluid then flows to the desander (removing 74–44 µm sand) and desilter (removing 44–20 µm clay).

- Back End – Centrifuge: Finally, the centrifuge removes ultra fine solids below 20 µm, producing clean fluid that returns to the well.

In the drilling fluid solids control process, the shale shaker is more than just a “cuttings separator” its performance directly impacts overall efficiency, equipment wear, and fluid reuse. Its core role, and why it is the front end key, is threefold:

- Reduces Downstream Load & Wear: If large cuttings bypass the shaker, they enter desanders and desilters, wearing impellers, liners, and risking blockages—increasing failures and shortening equipment life.

- Ensures Process Efficiency: A shaker with mismatched capacity can cause fluid overflow or delayed treatment, slowing the entire solids control process.

- Boosts Overall Fluid Recycling: Incomplete separation leaves solids that degrade fluid quality, making full performance restoration difficult even after deep cleaning. An efficient shaker enables staged, thorough purification, significantly raising total recycling rates.

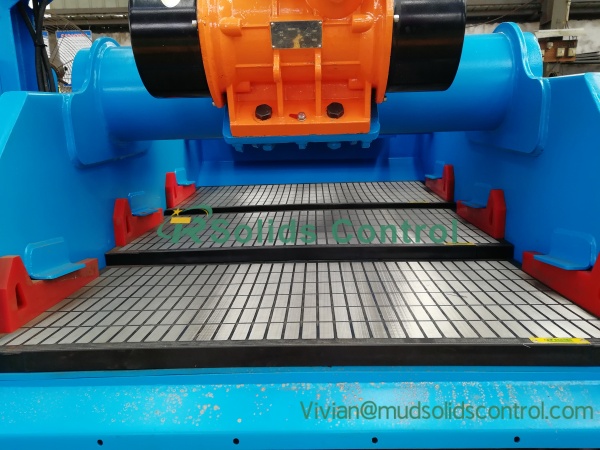

To meet the hierarchical and on site demands of the drilling fluid solids control process, TR solids control has optimized its shale shaker for efficient front end purification and seamless downstream integration. Its core design features align with actual process requirements:

- Multi Level Throughput: Screens in various sizes offer capacities from tens to hundreds of cubic meters per hour, matching drilling flow and system needs. Adjustable excitation force and deck angle allow real time tuning to fluid viscosity and solids, preventing overflow or delays.

- Dual Mode Vibration: Switchable linear and elliptical trajectories: linear for rapid separation in low viscosity, high volume fluid; elliptical for thorough cleaning of high viscosity, high solids mud, minimizing residue carry over.

- System Integrated Design: The shaker is developed alongside TR desanders, desilters, and centrifuges, with outlet size and flow rate precisely matched to downstream inlets for plug and play operation.

- Quick Change Screens: A snap release screen clamp enables one person, tool free replacement in minutes. Durable polyurethane or stainless steel screens extend service life and minimize process interruptions.

Drawing on deep process knowledge and years of manufacturing experience, TR Solids Control has developed shale shakers that precisely meet operational needs. We also provide end to end process optimization solutions from initial purification to deep treatment ensuring full‑system coordination and efficiency.

Moving forward, TR will continue to be guided by field needs, constantly improving our shakers and complete solids control line to deliver reliable support for efficient, stable fluid treatment operations and help drilling projects achieve cost savings, productivity gains, and greener performance.

Drilling fluid shale shaker discount

In oil and gas drilling, the shale shaker is a core solids control device whose procurement cost significantly impacts project budgets. Choosing a cost effective purchasing method can lower equipment investment without sacrificing quality, improving overall project efficiency.

Deeply experienced in solids control, TR Solids Control recognizes customers cost concerns. For its full range of shale shakers, TR offers favorable industry-tailored policies that move beyond low-price, low-quality models. This enables customers to obtain both procurement discounts and high-quality, site-suitable equipment with full service support, making TR a preferred shaker partner for drilling companies.

TR drilling fluid shaker purchasing plans are tailored to drilling-company needs, offering clear, transparent discounts for various buying scenarios.

- Volume-Based Discounts: Larger purchases receive greater per‑unit discounts, with free shipping, installation, and commissioning—ideal for block-wide or large-project procurement.

- System-Package Discounts: Higher discounts apply when purchasing complete solids-control systems, including custom layout design for better equipment synergy and fluid‑treatment efficiency.

- Loyal-Customer Discounts: Returning customers receive repurchase discounts, complimentary maintenance service, and free wear‑part gifts.

- Seasonal & Promotional Offers: Limited-time discounts across all shaker models suit small-to medium-scale purchasing, providing cost-effective buying opportunities.

TR Solids Control discounted shale shakers maintain full quality by leveraging direct factory production, eliminating middle-man costs without compromising performance.

- No Reduction in Core Specs: Discounted units still feature a Q345B alloy steel screen box, IP65-rated motor, wear-resistant polyurethane screens, switchable linear/elliptical vibration, and adjustable excitation force and deck angle. All meet industry standards for onshore, offshore, and shale gas drilling.

- Full-Process In-House Production: Every shaker is manufactured in-house under ISO-controlled processes—from materials and machining to final testing—ensuring reliability and stability before delivery.

- Genuine Quality Consumables: Included wear parts (screens, damping springs, etc.) are original TR-made components with superior wear and corrosion resistance, extending service life and reducing long-term operating costs.

TR Solids Control discounted shaker procurement is simple and fully supported, with no complex procedures, so customers can secure savings quickly.

Discounted procurement is an effective way to lower costs—provided you choose a reputable manufacturer with transparent policies and proven quality. As a professional solids-control manufacturer, TR leverages direct factory advantages to offer diverse, clear discount programs. These allow you to control procurement costs while receiving reliable, high‑performance shakers and full service support.Choosing TR discounted shaker program ensures equipment quality and helps manage project costs, making your drilling‑fluid treatment more efficient and economical.

Oilfield Mud Shale Shaker

Drilling mud is the “blood” of the well, cooling the bit, lubricating tools, and balancing pressure. When it returns to the surface, it carries solids like cuttings and sand. Without immediate separation, mud performance degrades, tools wear faster, and risks such as stuck pipe increase.

The shale shaker solves this. A vibration motor drives the screen bed at high frequency, quickly separating cuttings from the fluid. Liquid and fines pass through for further treatment, while larger solids are discharged. This restores mud properties, improves recycling, lowers fresh mud costs, and is indispensable in drilling operations.

Oilfield drilling presents diverse, challenging conditions, with variations in mud viscosity, solids, and flow rates requiring highly adaptable shale shakers. TR solids control has tailored its shakers for oilfield mud, delivering targeted technical features:

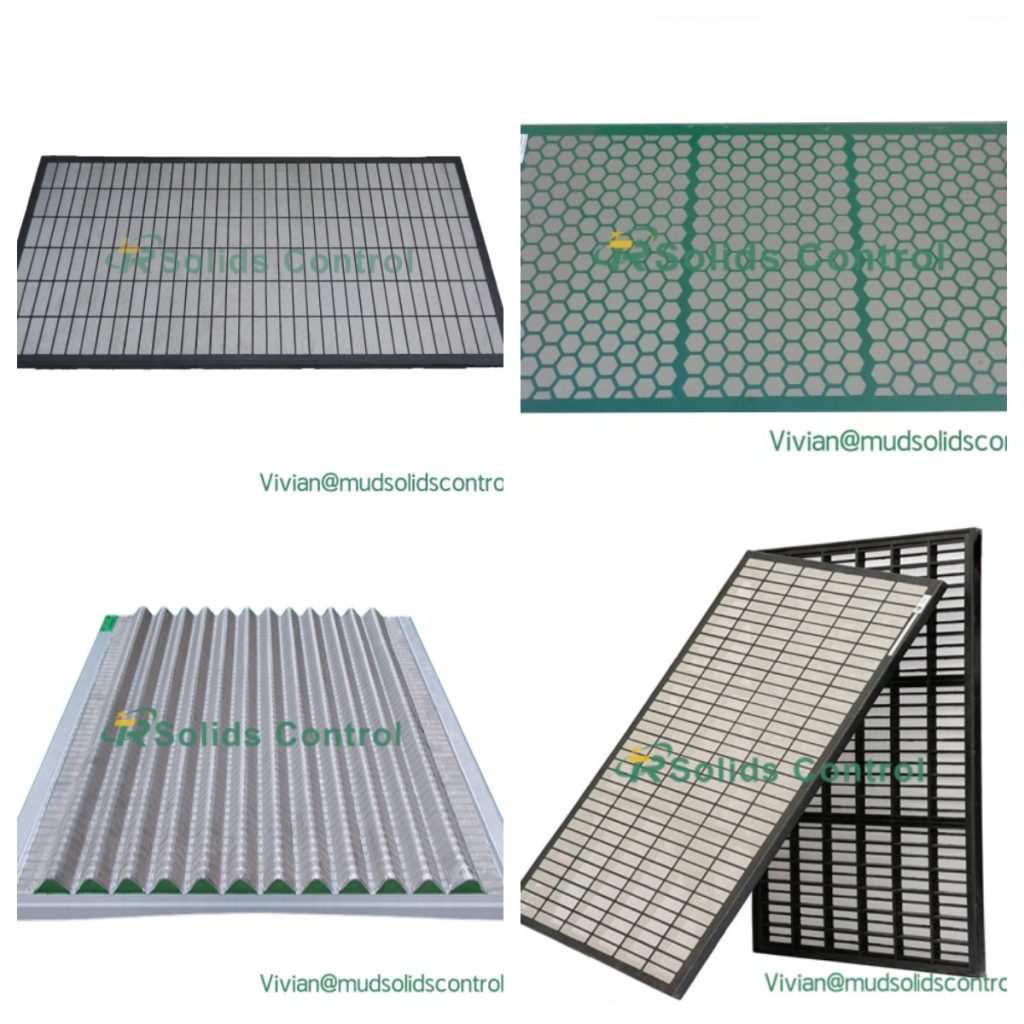

- Anti-Blinding Screen Design: Wear-resistant polyurethane screens with anti-clogging openings prevent sticking in high-viscosity mud. Available in 20-200 mesh to match cuttings size, balancing accuracy and throughput. Quick‑release buckles allow one-person screen changes, reducing downtime.

- Dual-Mode Vibration: Switchable linear and elliptical vibration modes. Linear handles high-volume mud rapidly; elliptical improves screening in high-solids mud. Adjustable excitation and amplitude suit varying block conditions, including shale and tight oil.

- Durable, Corrosion-Resistant Build: The screen box is fully welded Q345B alloy steel with heavy-duty anti-corrosion coating, built for humid, saline oilfield sites. A composite-spring damping system absorbs operational impact, reduces machine vibration, and extends service life.

In oilfield drilling, the shale shaker works as part of a complete TR solids control purification chain alongside desanders, desilters, and centrifuges.

After initial separation by the shaker, mud flows to the desander (removing 20-74 µm sand), then the desilter (removing 2-20 µm clay), and finally undergoes deep purification in a centrifuge. The cleaned mud is returned to the well for reuse.

This multi-stage process can raise mud reuse rates above 90%, lowering both procurement costs and waste discharge, in line with green drilling principles.

When selecting an oilfield shale shaker, match it to your specific block conditions by focusing on three aspects:

- Capacity – Ensure the rated flow matches your drilling output to avoid overflow or oversizing.

- Adaptability – For high-viscosity, high-solids mud, choose units with switchable vibration modes and anti‑blinding screens.

- After-Sales Support – Verify the supplier can supply parts and provide prompt on-site technical assistance.

TR Solids Control offers tailored shaker solutions based on your geology and drilling parameters. We support the entire process—installation, commissioning, training, and spare parts—through our extensive service network.

API-certified Shale Shaker Manufacturer

API certification for shale shakers is a comprehensive assessment, covering materials, manufacturing, and final performance, all aligned with real drilling conditions. It sets clear standards for performance, design, and quality control.

- Screen Specifications: API defines strict requirements for mesh size (API 20–400), material, and separation accuracy. Screens must match drilling fluid particle size and offer wear and corrosion resistance.

- Manufacturing Process: Production follows API-recommended practices and standards like SY/T 5612-2018. Welding, assembly, and anti-corrosion treatments are standardized to ensure reliability in harsh drilling environments.

- Performance Parameters: Key metrics-including capacity, vibration mode, and excitation force-must meet API requirements. Screens must provide stable solid‑liquid separation, reduce downstream load, and comply with industry standards for noise, stability, and uptime.

As a professional API-certified manufacturer, TR Solids Control integrates API standards throughout the entire product lifecycle—from R&D and production to inspection—while aligning with real‑world drilling needs. This results in standardized, practical shakers with distinct manufacturing strengths.

- Full-Process API Control: From material selection (Q345B alloy steel, 316L stainless steel, API-compliant fasteners) through production, TR adheres to ISO9001 and API requirements. Multiple inspections and quality oversight ensure every unit meets API certification standards.

- Certified & Adaptable Products: API-certified shakers offer both linear and elliptical motion, with capacities to match drilling flow rates. Screens use API-grade wear‑resistant polyurethane or 316L stainless steel, available in API 40-325 mesh. Configurations can be tailored for onshore, offshore, or shale gas operations to ensure precise fluid purification and cuttings separation.

- TR API-certified screens feature a multi-layer design: a coarse bottom layer for strength and a fine top layer for separation accuracy. This structure provides a large filtration area without sacrificing durability, improving fluid‑processing efficiency and screen life. The quick-install design allows fast replacement, minimizing on-site maintenance time.

As an API-certified manufacturer, TR Solids Control provides comprehensive pre-and after-sales support for drilling companies.

- Professional Selection Guidance: Our technical team recommends suitable API-certified shaker models and screen configurations based on your geology, fluid type, and operational scale.

- Standardized Installation & Training: We provide on-site installation, commissioning, and operator training to ensure correct, compliant use and maintenance of API‑certified equipment.

- Complete After-Sales & Spare Parts: A dedicated service team offers prompt technical support. We also supply original-manufacturer API-certified spare parts (screens, motors, springs) to ensure compatibility and long-term reliability.

In oil and gas drilling, API-certified shale shakers signify both quality and operational safety. Their standardized manufacturing and reliable performance enhance fluid‑purification efficiency, lower operational costs, and meet international market requirements.

When selecting an API-certified shaker, verify the manufacturer’s valid credentials, complete certification reports, production capacity, and after-sales service. As a professional API-certified manufacturer, TR Solid Controls provides full certification, mature production, and comprehensive support—ensuring shakers perform to their full potential in any drilling operation.

API certification reflects shaker manufacturing quality and aligns with the trend toward professional, standardized drilling equipment. TR Solid Control Equipment continuously optimizes design and production around API standards, delivering high-quality, certified solid-control equipment that supports efficient fluid purification and cuttings separation—making us a trusted partner for drilling companies.

Shale Shaker Drilling equipment manufacturer

Shale shakers production must strictly adhere to industry standards to ensure reliability in demanding drilling environments. TR solids control manufactures its shale shakers in full compliance with SY/T 5612-2018 and the ISO 9001 quality system, with multiple inspections from materials to finished product.

- Material Selection – The screen box is constructed from Q345B alloy steel or 316L stainless steel to withstand humid, corrosive drilling sites. All fasteners use 304 stainless steel for enhanced wear and corrosion resistance.

- Production Process – The screen box undergoes full heat treatment to endure continuous high‑intensity operation. Coating thickness is strictly controlled—≥250 μm on the screen box and ≥200 μm on other areas—ensuring robust outdoor performance.

As a professional manufacturer, TR Solids Control combines field experience with R&D to produce practical, adaptable vibrating screens.

- Multi-Mode Vibration: Switchable linear/elliptical modes with adjustable intensity (up to 8.5G) and amplitude (5-10mm) efficiently handle high-volume and high-viscosity fluids. Supports single-screen capacities for common field needs and meshes up to 200 for precise purification.

- User-Friendly Design: Quick-press screen clamping enables one-person replacement, cutting downtime. Some models allow live angle adjustment (–1° to +5°) for real‑time optimization. Few wear parts simplify daily maintenance.

- Reliable Components: Equipped with Martin/OLI vibration motors and Siemens/Schneider electrical parts. Motors feature class-F insulation, ≥IP54 protection, and ExdIIBt4 explosion‑proof rating for rig safety. Composite spring damping lowers noise below 85 dB(A).

As a professional manufacturer, TR Solids Control designs shale shakers for a wide range of applications—from onshore oil & gas drilling (vertical, horizontal, and shale gas wells) to offshore platforms, slurry tunneling, pile foundations, dredging, and mining tailings.

To match specific site needs, TR offers customized solutions. Examples include compact, corrosion-resistant shakers for offshore platforms and small, mobile units for tunneling projects. Their shakers also integrate seamlessly with desanders, desilters, and centrifuges, forming a complete, company-wide fluid-purification system.

Beyond its established R&D and manufacturing expertise, TR Solids Control delivers full-cycle support from equipment selection and commissioning to after-sales service. Our technical team recommends shaker models and configurations based on your drilling conditions, geology, and scale. After delivery, we provide free on-site installation guidance and operator training, backed by a comprehensive spare‑parts supply and responsive after-sales support.

In product development, TR continually invests in R&D to align with industry trends and field requirements. We enhance shaker performance through innovations such as variable-frequency excitation control and anti-splash designs, ensuring our products meet evolving operational needs.

Manufacturing quality is fundamental to drilling-equipment reliability. Choosing a professional manufacturer like TR ensures your equipment delivers full value. Through standardized production, condition-driven design, and complete after‑sales support, TR creates high-quality solid-control equipment that provides dependable performance across drilling operations—making us a trusted partner for drilling companies.

Shale Shaker – Drilling Fluid

Drilling fluid, known as the “blood” of drilling operations, cools the bit, lubricates tools, and balances formation pressure. When it returns to the surface, it carries rock cuttings and solids that must be removed to avoid fluid degradation, stuck pipes, or wellbore collapse.

The shale shaker serves as the first defense in fluid purification. A vibration motor drives the screen bed at high frequency, separating cuttings from the fluid. Liquid and fine particles pass through for further treatment, while larger cuttings are discharged. This process restores fluid properties, reduces the need for new fluid, and lowers operational costs through recycling.

Drilling fluid properties like viscosity, density, and solids content vary widely across different conditions, requiring highly adaptable shale shakers. TR solids control has addressed this need with targeted design improvements:

- Dual Vibration Mode – Features switchable linear and elliptical vibration trajectories. Linear mode rapidly processes low‑viscosity, high‑volume fluids, while elliptical mode prevents screen blinding in high‑viscosity, high‑solids fluids such as those used in shale gas drilling.

- Customizable, Wear-Resistant Screens – Offers polyurethane and high‑manganese steel screens in 20-200 mesh sizes to match particle-size requirements. The quick-release buckle design enables tool-free screen replacement, minimizing downtime.

- Enhanced Corrosion Resistance – For corrosive environments (e.g., saltwater or acidic muds), key components such as the basket and frame are constructed from 316L stainless steel and coated with heavy‑duty anti‑corrosion protection, extending service life in harsh conditions.

In drilling operations, the shale shaker works within a complete TR solids control system, forming a multi‑stage purification chain together with desanders, desilters, and centrifuges.

Fluid first passes through the shale shaker for initial solids removal, then flows to the desander (20-74 µm) and desilter (2-20 µm), and finally to the centrifuge for deep purification. The cleaned fluid is returned to the drilling process.

This coordinated, staged approach can raise fluid recycling rates to over 90%, minimizing waste fluid consumption and disposal while supporting greener drilling operations.

To ensure continuous, stable performance from a shale shaker, proper selection and regular maintenance are essential.

- Selection: Match the shaker capacity and vibration mode to your drilling fluid flow, viscosity, and solids content. Materials and protection levels should also be chosen based on site conditions. TR Solid Control Equipment offers professional guidance and model recommendations tailored to your fluid parameters.

- Maintenance: Regularly inspect screens for wear or blockage and replace as needed. Lubricate core components such as the vibration motor and bearings, and keep the equipment clean to prevent corrosion from fluid residue.

Effective shaker-fluid coordination is key to smooth drilling operations. Drawing on deep expertise in fluid handling, TR Solids Control delivers shakers with stable performance and high adaptability, providing practical solutions for drilling fluid purification and recycling.