Tag Archives: Drilling Shale Shaker

9671640 Screen Frame Weldment for Mongoose Shaker

One of the critical components that contribute to these factors is the 9671640 screen frame weldment.9671640 screen frame weldment highlighting role in enhancing the performance of the Mongoose shaker.

The Mongoose shaker is a vital piece of equipment used in the drilling process to separate solids from drilling fluids.Its efficient design allows for high-capacity processing, making it a preferred choice in various drilling operations.The shaker ensure that the drilling fluid is clean and reusable, which is essential for maintaining operational efficiency and reducing costs.

The Role of the 9671640 Screen Frame Weldment

The 9671640 screen frame weldment is an integral part of the Mongoose shaker. This component serves as the structural backbone that supports the shaker screens. The weldment is designed to withstand the rigors of drilling operations, including exposure to harsh environments and heavy loads. It is robust construction ensures that it can handle the vibrations generated during the shaking process without compromising its integrity.

The 9671640 screen frame weldment is constructed from high-quality materials that are resistant to wear and tear.

The weldment is manufactured with precision to ensure a perfect fit with the Mongoose shaker.

the 9671640 screen frame weldment can be easily installed or replaced.

Designed for compatibility with the Mongoose shaker.

By providing a stable and secure platform for the shaker screens.The 9671640 screen frame weldment contributes to the overall performance of the Mongoose shaker.

Benefits of Using the 9671640 Screen Frame Weldment

The 9671640 screen frame weldment can lead to significant cost savings over time. It is durability reduces the frequency of replacements.9671640 screen frame weldment efficiency enhances the overall productivity of the drilling operation.

screen frame weldment minimizes the risk of equipment failure.

The 9671640 screen frame weldment is a crucial component that enhances reliability of drilling operations. It is durable construction make it an invaluable asset in the oil and gas industry. The 9671640 screen frame weldment a key player in the future of drilling technology.

Contact us today to learn more about SWACO Spring Coil and shaker screens, how TR can support your solids control needs with innovative solutions.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

www.solidscontrolequipment.com

Replacement Derrick Shaker

One of the key components that contributes to this efficiency is the Replacement derrick shaker. Replacement derrick shaker can significantly impact the overall performance of a drilling rig.

Replacement derrick shaker is an essential piece of equipment in the drilling process. Used to separate the drilling fluid from the cuttings produced during the drilling process. Replacement derrick shaker use a series of screens to filter out solid particles, allowing the clean fluid to be reused in drilling operations. This not only saves resources but also improves the overall efficiency of the drilling process.

The necessity of Replacement derrick shaker

When a derrick shaker is inefficient, it can cause several problems, including:

- Increased Downtime.

- Poor Fluid Management.

- Higher Operating Costs.

To mitigate these issues, investing in a replacement derrick shaker is critical. New shakers can restore peak performance, ensuring drilling operations remain efficient and cost-effective.

Select the appropriate replacement derrick shaker

When choosing to replace a derrick shaker, the following factors should be considered:

- Compatibility.

- Performance Specifications.

- Durability.

- Maintenance Requirements.

- Cost Effectiveness.

Advantages of replacement derrick shaker:

- Improved Efficiency: New shakers enhance the separation process, allowing for better fluid management and less waste.

- REDUCED DOWNTIME: With reliable vibrating screens, you can reduce the risk of operational interruptions, resulting in a more consistent drilling schedule.

- Cost Savings: Increased efficiency and reduced downtime mean lower operating costs, making the investment worthwhile.

Replacement derrick shakers can play a key role in achieving this goal. By carefully selecting high-quality alternatives, operators can improve drilling efficiency.This is a strategic move towards long-term success for the drilling industry.

We are an exporter of shaker screen.TR is a Replacement Derrick Shaker maufuacturer and china Hyperpool screen supplier.Our factory approval the API,Drilling Shale Shakers and drilling PMD shaker screen have the API certification.TR solids control is the designed,selling,production,service and delivery of Chinese drilling fluid shakers manufacturers.We will provide the high quality shaker screen and swaco mongoose shaker screen.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:18509252400

E-mail:sales@trsolidscontrol.com

Shale Shaker for Mud System

the Shale Shaker for Mud System plays a crucial role as the unsung hero that ensures smooth and efficient operations.

How Shale Shaker for Mud System Work

Shale shakers function based on the principles of vibration and screening.The drilling mud is introduced onto a vibrating screen deck. which oscillates to facilitate the separation of solid particles from the liquid phase.The separated solids are subsequently discharged from the shaker, whereas the purified mud is redirected back into the mud system for reuse.

Features and Benefits of Shale Shaker for Mud System

The shale shaker for mud system is an indispensable tool for any mud system.Its ability to efficiently separate solid particles from drilling mud is crucial for maintaining the performance and longevity of drilling equipment. investing in a quality shale shaker is essential for ensuring a successful and cost-effective drilling operation.

The Importance of Shale Shakers

The shale shaker serves as a critical component within any mud circulation system. This separation process is crucial for several reasons.It plays a key role in preserving the quality and efficacy of the drilling fluid. it prolongs the lifespan of drilling equipment.Solid particles can considerable wear and damage on pumps, pipes within the drilling apparatus. The shale shaker mitigates risks associated with equipment failure and minimizes costly downtime.

The shale shaker for mud system is an indispensable tool for any mud system.Its ability to efficiently separate solid particles from drilling mud is crucial for maintaining the performance and longevity of drilling equipment. investing in a quality shale shaker is essential for ensuring a successful and cost-effective drilling operation.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

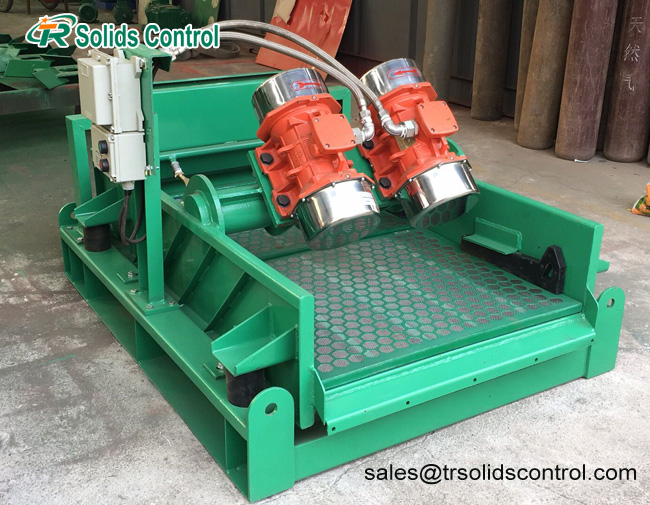

Drilling Shaker

Drilling shaker,also known as shale shakers. It is a key equipment used in the drilling industry.It function is to separate the drilled cuttings from the drilling fluid to ensure the cleanliness of the drilling fluid.

Function and principle of Drilling Shaker

The main parts of drilling shaker are vibration motor and screen. When the drilling fluid returns from the wellbore into the shaker. Shaker screen vibrates liquid and cuttings through the screen. The smaller cuttings pass through the screen while the larger cuttings are removed.

Drilling shakers are generated by an electric or hydraulic motor driving an eccentric weight or vibrating mechanism. Adjust the vibration amplitude and frequency according to drilling conditions and cuttings type

Type of Drilling Shaker

This type of shaker has linear vibration motion and is commonly used in onshore drilling operations. It provides high capacity and efficient cuttings separation.

Elliptical motion shaker combines linear and circular motion to provide a gentler and more efficient separation. It is suitable for both onshore and offshore drilling.

This advanced type of shaker offers better balance and reduced vibration transmission, resulting in longer equipment life and better performance.

Drilling Shaker Application Program

Drilling shakers are essential in oil and gas drilling operations to separate cuttings from drilling fluids and maintain the integrity of the drilling process.

In geothermal drilling, drilling shakers help remove cuttings, keep drilling fluid circulating, and ensure efficient heat extraction.

Drilling shakers are used in mining operations to separate cuttings from drilling fluids and improve drilling efficiency.

In water well drilling, drilling shakers are used to remove soil and sediment from drilling fluids, ensuring a clean water supply.

Drilling shaker is an essential tool in the drilling industry. It effectively and reliably separates cuttings from drilling fluids and is a key component in ensuring successful drilling operations.

TR Solids Control is a professional manufacturer of mud shale shakers and solid control equipment. TR can provide replacement mud shale shaker of derrick, swaco mongoose shakers. If you need any one model drilling shale shaker, TR solid control will provide you with a high quality mud solids control equipment. We can also customize the shale shaker for your requirements.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

Shale Shaker in Drilling

Shale Shaker in Drilling separates the cuttings from the drilling fluid. When the drilling fluid returns to the surface, it carries with it the cuttings produced by the drill bit. Shale Shaker in Drilling uses shaker screen to filter out cuttings. Shale shakers help maintain the quality and properties of drilling fluid, which is critical to the drilling process. Clean drilling fluid ensures better lubrication and bit cooling. Recovering drilling fluids reduces the need for fresh drilling fluids, further reducing costs.

There are several types of Shale Shaker in Drilling. TR produces single and double Shale Shakers as well as triple shale shakers.

Fellow drillers, are you struggling with drilling efficiency and quality?

Our shale shaker in drilling is a great choice for you. Using advanced technology, it is durable and can efficiently separate solid particles in drilling fluid. The precise screening function ensures the purity of drilling fluid and improves drilling speed and quality. Secure your drilling project with our shale shaker and start a new era of efficient drilling.

Shale Shaker in drilling uses an innovative design concept to make its compact structure and small footprint easy to install and use on the drilling site. At the same time, its operation is simple and convenient, even staff without professional technical background can easily get started.

In terms of quality, we strictly control every link. From the selection of raw materials to the control of the production process, we strive for excellence. This makes our Shale Shaker extremely reliable and durable, providing consistent performance over long periods of time.

Shale Shaker in drilling uses very little energy, makes very little noise, and has a minimal impact on the environment. This not only meets the environmental requirements of modern society, but also saves costs for drilling companies.

If you’re struggling to find a good Shale Shaker in drilling, give our product a try. We are sure that it will bring you a surprise.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

TRZS503 Shale Shaker

TRZS503 Shale Shaker is a solids control equipment, which plays an important role in drilling mud treatment system. In the drilling mud treatment system, the FLC503 shaker is the leader. Meeting the demanding requirements of drilling operations, the FLC503 shaker ensures efficiency, reliability and superior performance.

The TRZS503 shale shaker can replace the FLC503 shale shaker.

TRZS503 shale shaker is composed of a vibrating motor and a screen box and a control box. TRZS503 shale shaker accessories can replace the FLC503

shale shaker . The TRZS503 shale shaker is mainly used to separate solids from drilling fluids to ensure that drilling mud is clean. Shaker work is very important to maintain the continuity of drilling operations and ensure the safety of the entire drilling process.

Advantages of TRZS503 Shale Shaker

- High efficiency

The FLC503 shale shaker is carefully designed to deliver superior performance. Its advanced design and robust construction allow it to easily handle large volumes of drilling mud, ensuring effective separation of solids from fluids. This means reduced downtime and increased productivity in drilling operations. - Durability and reliability

FLC503 shale shaker is made of Q345R alloy material. Able to withstand the harsh conditions of drilling environments. Its durable design ensures long-lasting performance and reduces the need for frequent maintenance and replacement. Derrick screens are suitable for TRZS503 shale shaker. - Large scope of application

The FLC503 shaker is designed for a wide range of drilling applications. Whether you’re drilling for oil, gas or geothermal, this shaker meets all drilling fluid and solids control requirements. It is adaptability makes it a valuable addition to any drilling operation. - Strong substitution

The TRZS503 shale shaker can replace the FLC503 shale shaker. swaco shaker can also be replaced.

The FLC503 shale shaker is a proof of excellence in drilling mud handling. Using FLC503 shale shaker, drillers can improve operational efficiency, reduce downtime and contribute to a more sustainable future. Embrace the future of drilling mud handling with the FLC503 Shale Shaker and experience the difference it can make to your operations.

We are an exporter of Drilling Mud Shale Shaker. Our factory approval the API, shale shakers have the API certification. TR solids control is the designed, selling, production, service and delivery of Chinese drilling fluids shale shaker manufacturers. We will provide the high quality shale shakers and best service. Your best shale shaker start from TR solids control.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

www.solidscontrolequipment.com

Shale Shaker Price Comparison

One of the key components of the drilling process is the mud shaker, a device used to remove cuttings from the drilling fluid. Understanding shaker price comparisons is important to make an informed buying decision. TR has researched shale shaker price comparison to help you make the right choice.

The factors that affect the price of the shaker can determine Shale Shaker Price Comparison

Well-known brands often demand higher prices. They also offer better assurance and customer support.

More expensive mud shakers have higher processing capacity. The size of the shaker should match the size of the rig.

Shakers with advanced performance cost high, such as adjustable gravity, multi-deck configuration can increase the price. These characteristics can significantly improve the separation performance and efficiency of the shaker.

After Shale Shaker Price Comparison, we can know that different manufacturers and different specifications of vibrating screen are factors that affect the price.

When purchasing shale shaker price comparison, not only the initial cost should be considered, but also the long-term value. A high quality shaker can lead to better performance. Such as reduced downtime, lower maintenance costs, and ultimately save money in the long run. By understanding the factors that affect prices and evaluating different brands and models, you can make informed decisions to meet your operational needs and budget constraints.

We are an exporter of Drilling Mud Shale Shaker. Our factory approval the API, shale shakers have the API certification. TR solids control is the designed, selling, production, service and delivery of Chinese drilling fluids shale shaker manufacturers. We will provide the high quality shale shakers and best service. Your best shale shaker start from TR solids control.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

www.solidscontrolequipment.com

Type of Shale Shaker

There are many type of shale shaker. It is generally classified according to the mode of movement and classified according to the structure. At present, the linear type of shale shaker is very popular.

The following are the type of shale shaker

Balanced elliptical motion shale shaker:

This type of shale shaker, if tilted downward towards the discharge end, is as effective as a straight line in removing viscous material. And because of its increased physical size (and consequent increase in the surface area of the screen plate), finer screens can be used than in circular or elliptical motions.

Linear motion shale shaker:

The vibration mechanism of linear motion helps to effectively separate solid and liquid, and is one of the common motion modes of shale shakers. In drilling operations, this motion can steadily separate cuttings from the drilling fluid.

Single deck shale shaker:

The structure is relatively simple, and it is suitable for some cases where the solid separation requirements are not particularly high or the drilling conditions are relatively simple.

Double-deck shakers:

SLB’s double-deck and flat-deck shakers, for example, can quickly adapt to changing drilling conditions and effectively separate solids under different drilling conditions.

Three-deck shaker:

Three-deck shakers like the SLB meet the requirements of efficiency, flexibility and rig space in a compact construction for a variety of drilling environments.

Some of the company’s types of shale shaker products

M-I SWACO (Schlumberger)

Various types of shale shakers are available, such as double deck and three deck shakers. Its products provide consistently high quality solids control performance on land or at sea.

Halliburton (Halliburton)

They carefully select and qualify every shale shaker in their comprehensive product range and work directly with customers to determine the best solution for their operational needs to effectively remove solids and maintain reliability.

NOV (National Oilwell Varco)

The AX-1 shale shaker has excellent raw processing capacity and solid separation efficiency to handle high circulation rates and is suitable for fast surface drilling. And can improve the separation effect by sequential screening, extend the life of very fine mesh screen.

There are many type of shale shaker produced by TR. We are an exporter of Drilling Mud Shale Shaker. Our factory approval the API, shale shakers have the API certification. TR solids control is the designed, selling, production, service and delivery of Chinese drilling fluids shale shaker manufacturers. We will provide the high quality shale shakers and shaker screen. Your best shale shaker start from TR solids control.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

www.solidscontrolequipment.com

Shale Shaker Drilling

shale shaker drilling is a drilling equipment component that removes large solids from drilling fluid, or mud, during the drilling process. It’s the first step in a drilling rig’s solids control system.

Shale Shaker drilling is a device used in drilling mud cleaning systems to remove larger cuttings from the mud. Shale shaker plays an important role in oilfield drilling. It helps to maintain the cleanliness of drilling fluid, prevent the clogging of drilling equipment, and improve the overall drilling efficiency. The correct selection and design of the mud shaker can effectively remove the solid particles in the drilling fluid, thus ensuring the smooth drilling process.

Shale Shaker works by vibrating to separate solid particles and large pieces of drilling fluid. The shaker is designed to handle large volumes of drilling fluid while effectively removing unwanted components to improve the effectiveness of subsequent solids control systems.

Shale Shaker Drilling for drilling process

Shale Shaker drilling plays a key role in the drilling process, particularly in solids control systems. Its main task is to filter out large particles of cuttings in the drilling fluid to protect subsequent solids control equipment and the drilling process itself. If these large particles of cuttings are not effectively removed, they can lead to clogging of drilling mud pumps and other equipment, affecting drilling efficiency and even causing equipment damage.

There are many types of mud shale shaker drilling, each with its own unique characteristics and applications. Factors to consider when choosing a shale shaker include the amount of liquid to handle, the design of the shaker, and the characteristics of the drilling fluid.

We are an exporter of Drilling Mud Shale Shaker. Our factory approval the API, shale shakers have the API certification. TR solids control is the designed, selling, production, service and delivery of Chinese drilling fluids shale shaker manufacturers. We will provide the high quality shale shakers and best service. Your best shale shaker start from TR solids control.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

www.solidscontrolequipment.com

Mongoose Shale Shaker

Mongoose shale shaker is a widely used shaker in the petroleum industry that plays a vital role in the purification of drilling fluids. It is mainly used to treat solid particles in drilling fluid to ensure that drilling fluid can be recycled and improve drilling efficiency.

In order to reduce fine particles in drilling fluid, in addition to using solid control equipment, dilution and other measures, it is important to reduce the production of fine particles at the source. As an important solid control equipment, the Mongoose shale shaker plays a key role in the drilling process. It works at the same time with solid control equipment such as cleaners and centrifuges to properly remove the sand in the sand settling tank.

Mongoose shale shaker has many advantages

1. It’s screen cloth can be used for 200 mesh without running mud. This can more effectively filter the solid particles in the drilling fluid and improve the purity of the drilling fluid.

2. The mesh frame has high strength, strong and firm, flat mesh surface, and good screening permeability. Compared to traditional screens, the Mongoose shale shaker has a longer service life, which is five times longer than the average screen. Moreover, the installation is very convenient and easy to disassemble, which greatly improves the work efficiency.

3. Mongoose shale shaker is typically 1165X585X40mm in size and is suitable for specific types of shakers. For example, the MI Swaco Mongoose Shale Shaker is a companion device. It has excellent performance in the filtration and removal of solid particles in petroleum drilling fluid, which provides a strong guarantee for the smooth progress of oil drilling operations.

Contact us today to learn more about our shale shaker specifications and shaker screens, how TR can support your solids control needs with innovative solutions.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com