Drilling Fluid Shale Shaker Manufacturers

In oil and gas drilling, the shale shaker is the first critical unit in solids control, directly impacting cuttings separation, fluid recycling, and operating costs. Choosing a professional manufacturer is essential for performance and full service support.

With many suppliers varying in quality and service, selecting the right partner is a key decision. TR Solids Control, a specialist shaker manufacturer, has built an integrated R&D-production-service system through years of technical and market experience. We stand out in product performance, customization, and after-sales support, providing drilling companies with complete equipment and technical solutions.

Core Selection Criteria for Drilling Fluid Shale Shaker Manufacturers

- R&D & Technical Capability: An independent R&D team is essential to optimize designs for special conditions (e.g., high viscosity fluids, marine corrosion). Key technologies include dual mode vibration and wave screen designs, supported by proprietary patents.

- Quality & Certification: Equipment should meet API and ISO standards. A full quality control system—from materials to final inspection—ensures wear resistance, corrosion resistance, and stable operation.

- Customization Ability: Manufacturers must tailor shakers to specific conditions: capacity, screen specs, installation size, etc. Examples include compact units for tight sites and corrosion resistant models for offshore platforms.

- Comprehensive After Sales Service: A broad service network is critical for on site installation, operator training, rapid fault response, and spare parts supply to minimize downtime in complex drilling environments.

Choosing TR as your shale shaker manufacturer delivers high quality equipment along with complete technical and service support, providing multiple operational benefits:

- Higher Fluid Processing Efficiency: Advanced vibration and screen designs achieve over 80% solids removal, reducing downstream workload and boosting overall system efficiency while enabling fluid recycling.

- Lower Drilling Costs: Reliable performance cuts downtime and extends equipment life. Efficient screening increases fluid recovery, reducing new fluid purchases and waste disposal expenses. Competitive pricing and full after sales service further lower total cost of ownership.

- Adaptability to Complex Conditions: A full product line suits everything from conventional drilling to shale gas and offshore operations, ensuring stable performance across diverse environments.

- End-to-End Technical Support: We assist from selection and customization through installation and operation—helping you optimize layout, train operators, and maximize equipment performance.

Selecting an unqualified shale shaker manufacturer can lead to poor processing efficiency, frequent breakdowns, higher maintenance costs, and increased drilling risks. In contrast, a reliable manufacturer like TR Solids Control delivers stable equipment and full support, effectively improving fluid purification efficiency, reducing costs, and ensuring operational continuity.

The choice of shaker manufacturer directly impacts drilling efficiency and expense. With strong R&D, a complete product line, customization, and comprehensive after sales service, TR has become a trusted partner for many drilling companies. Moving forward, TR will continue to focus on solids control innovation, optimizing performance to provide reliable equipment and solutions that help the oil and gas industry achieve lower costs and higher efficiency.

Shale Shaker: The Core of the Drilling Fluid Solids Control

The drilling fluid solids control process is a staged purification system. Its goal is to remove solids of varying sizes through coordinated equipment, restoring fluid viscosity and density for recycling thereby cutting costs and environmental impact. Arranged by particle size, the process begins with the shale shaker as the “first gate” of solids control.

- Front End – Shale Shaker: Fluid returning from downhole, carrying solids >74 µm, enters the shaker. High‑frequency vibration separates and discharges large cuttings, removing over 80% of solids and greatly reducing the load on downstream equipment.

- Mid Stage – Desander + Desilter: Fluid then flows to the desander (removing 74–44 µm sand) and desilter (removing 44–20 µm clay).

- Back End – Centrifuge: Finally, the centrifuge removes ultra fine solids below 20 µm, producing clean fluid that returns to the well.

In the drilling fluid solids control process, the shale shaker is more than just a “cuttings separator” its performance directly impacts overall efficiency, equipment wear, and fluid reuse. Its core role, and why it is the front end key, is threefold:

- Reduces Downstream Load & Wear: If large cuttings bypass the shaker, they enter desanders and desilters, wearing impellers, liners, and risking blockages—increasing failures and shortening equipment life.

- Ensures Process Efficiency: A shaker with mismatched capacity can cause fluid overflow or delayed treatment, slowing the entire solids control process.

- Boosts Overall Fluid Recycling: Incomplete separation leaves solids that degrade fluid quality, making full performance restoration difficult even after deep cleaning. An efficient shaker enables staged, thorough purification, significantly raising total recycling rates.

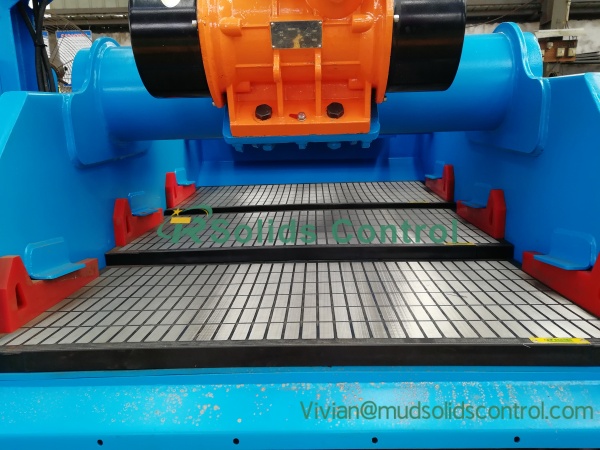

To meet the hierarchical and on site demands of the drilling fluid solids control process, TR solids control has optimized its shale shaker for efficient front end purification and seamless downstream integration. Its core design features align with actual process requirements:

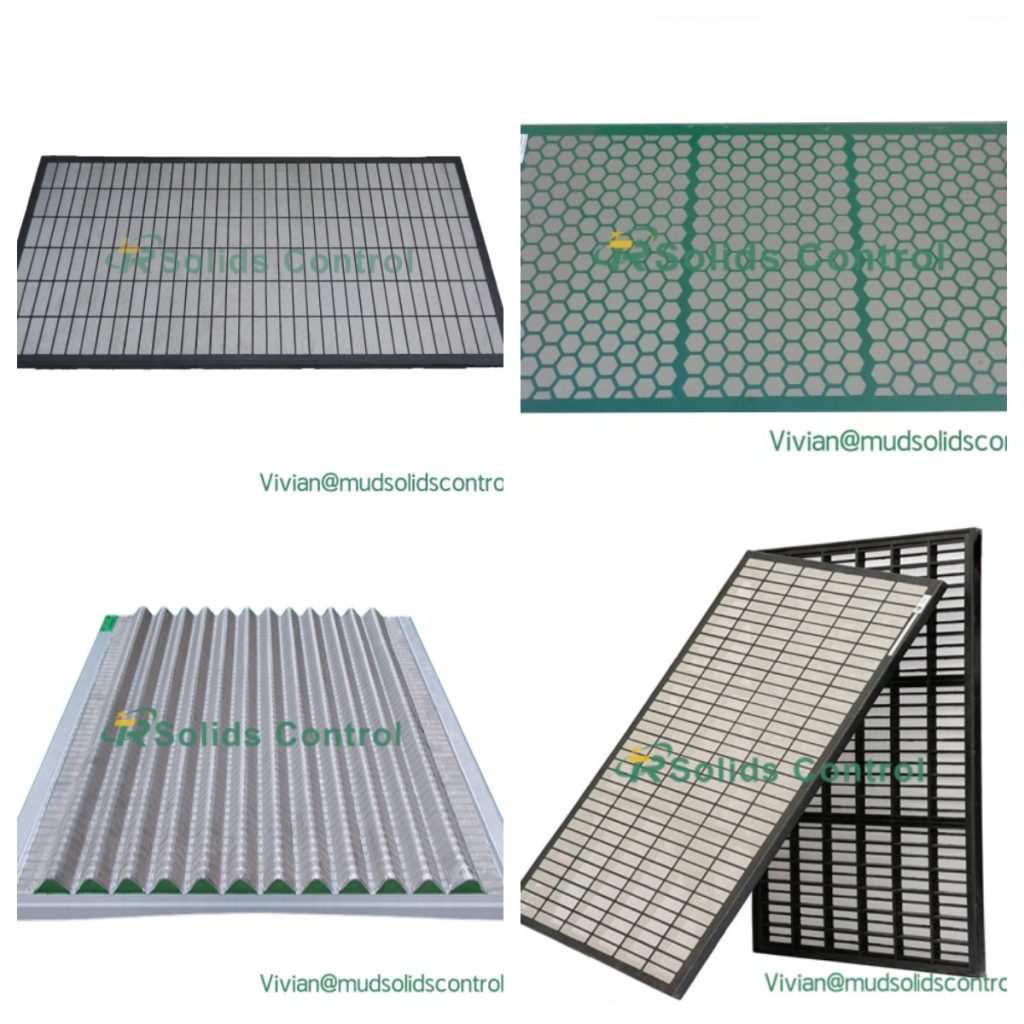

- Multi Level Throughput: Screens in various sizes offer capacities from tens to hundreds of cubic meters per hour, matching drilling flow and system needs. Adjustable excitation force and deck angle allow real time tuning to fluid viscosity and solids, preventing overflow or delays.

- Dual Mode Vibration: Switchable linear and elliptical trajectories: linear for rapid separation in low viscosity, high volume fluid; elliptical for thorough cleaning of high viscosity, high solids mud, minimizing residue carry over.

- System Integrated Design: The shaker is developed alongside TR desanders, desilters, and centrifuges, with outlet size and flow rate precisely matched to downstream inlets for plug and play operation.

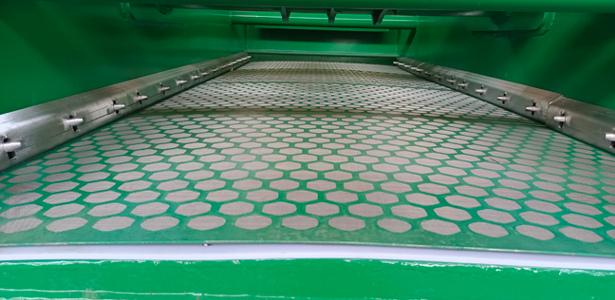

- Quick Change Screens: A snap release screen clamp enables one person, tool free replacement in minutes. Durable polyurethane or stainless steel screens extend service life and minimize process interruptions.

Drawing on deep process knowledge and years of manufacturing experience, TR Solids Control has developed shale shakers that precisely meet operational needs. We also provide end to end process optimization solutions from initial purification to deep treatment ensuring full‑system coordination and efficiency.

Moving forward, TR will continue to be guided by field needs, constantly improving our shakers and complete solids control line to deliver reliable support for efficient, stable fluid treatment operations and help drilling projects achieve cost savings, productivity gains, and greener performance.

Drilling fluid shale shaker discount

In oil and gas drilling, the shale shaker is a core solids control device whose procurement cost significantly impacts project budgets. Choosing a cost effective purchasing method can lower equipment investment without sacrificing quality, improving overall project efficiency.

Deeply experienced in solids control, TR Solids Control recognizes customers cost concerns. For its full range of shale shakers, TR offers favorable industry-tailored policies that move beyond low-price, low-quality models. This enables customers to obtain both procurement discounts and high-quality, site-suitable equipment with full service support, making TR a preferred shaker partner for drilling companies.

TR drilling fluid shaker purchasing plans are tailored to drilling-company needs, offering clear, transparent discounts for various buying scenarios.

- Volume-Based Discounts: Larger purchases receive greater per‑unit discounts, with free shipping, installation, and commissioning—ideal for block-wide or large-project procurement.

- System-Package Discounts: Higher discounts apply when purchasing complete solids-control systems, including custom layout design for better equipment synergy and fluid‑treatment efficiency.

- Loyal-Customer Discounts: Returning customers receive repurchase discounts, complimentary maintenance service, and free wear‑part gifts.

- Seasonal & Promotional Offers: Limited-time discounts across all shaker models suit small-to medium-scale purchasing, providing cost-effective buying opportunities.

TR Solids Control discounted shale shakers maintain full quality by leveraging direct factory production, eliminating middle-man costs without compromising performance.

- No Reduction in Core Specs: Discounted units still feature a Q345B alloy steel screen box, IP65-rated motor, wear-resistant polyurethane screens, switchable linear/elliptical vibration, and adjustable excitation force and deck angle. All meet industry standards for onshore, offshore, and shale gas drilling.

- Full-Process In-House Production: Every shaker is manufactured in-house under ISO-controlled processes—from materials and machining to final testing—ensuring reliability and stability before delivery.

- Genuine Quality Consumables: Included wear parts (screens, damping springs, etc.) are original TR-made components with superior wear and corrosion resistance, extending service life and reducing long-term operating costs.

TR Solids Control discounted shaker procurement is simple and fully supported, with no complex procedures, so customers can secure savings quickly.

Discounted procurement is an effective way to lower costs—provided you choose a reputable manufacturer with transparent policies and proven quality. As a professional solids-control manufacturer, TR leverages direct factory advantages to offer diverse, clear discount programs. These allow you to control procurement costs while receiving reliable, high‑performance shakers and full service support.Choosing TR discounted shaker program ensures equipment quality and helps manage project costs, making your drilling‑fluid treatment more efficient and economical.