Tag Archives: Drilling Shale Shaker

Shale Shaker Performance Comparison: Understanding the Key Differences

Conducting a shale shaker performance comparison is essential for operators who want to improve drilling fluid treatment efficiency. By analyzing parameters such as G-force, screen area, deck design, vibration modes, and processing capacity, you can better understand how different shale shaker models behave in real-world drilling environments.

1. Vibration G-Force

G-force affects how effectively solids are conveyed across the screen.

- Higher G-force → stronger conveying power and better drying of cuttings

- Lower G-force → reduced motion, suitable for fragile screens or gentle operations

Shakers using adjustable G-force allow more flexible operation across various drilling conditions.

2. Screen Area & Layout

Screen area is a critical element in a shale shaker performance comparison.

- A larger screen area supports higher flow rate

- Optimized screen layout (single-layer or multi-layer) enhances separation quality

Some modern units use composite screens to increase usable area and extend screen life.

3. Deck Angle Adjustability

Deck angle determines fluid pool depth and cuttings movement speed.

- A steeper angle improves solids discharge

- A flatter angle increases fluid retention time

Shakers featuring quick manual or hydraulic angle adjustment provide better control over changing mud properties.

4. Vibration Mode: Linear vs. Balanced Elliptical

Different vibration modes influence separation performance:

- Linear motion → powerful conveying, ideal for heavy solids and high-volume mud

- Balanced elliptical motion → smoother movement, suitable for fine solids removal

Operators often compare these modes when selecting equipment for specific drilling applications.

5. Processing Capacity

Capacity is defined by how much mud the shaker can handle per hour. Key influencing factors:

- Screen API rating

- G-force output

- Flow distribution design

- Motor power

A clear performance comparison helps determine which model meets the required operational throughput.

6. Screen Type Compatibility

Screen performance directly affects the shaker’s efficiency. Common differences include:

- Composite vs. steel frame

- API mesh rating

- Panel support design

Choosing a shaker compatible with widely available screens reduces operating cost and improves flexibility.

7. Energy Consumption

Energy efficiency is becoming a key evaluation point.

- Motors with optimized power usage lower overall cost

- Efficient vibration mechanisms reduce wear and extend equipment life

This factor often separates older shakers from modern designs.

Conclusion

A well-structured shale shaker performance comparison provides clear insights into how different models operate and which parameters matter most for solids control. By evaluating screen area, vibration force, deck angle, capacity, and energy usage, drilling teams can select equipment that aligns with their mud characteristics and operational demands.

Shale Shaker Installation Standards: A Practical Guide for Safe and Efficient Setup

When setting up a solids control system, following proper shale shaker installation standards is essential for achieving stable performance, long equipment life, and safe operation. In this guide, we break down the key requirements that drilling teams should follow during shaker installation, from foundation preparation to final commissioning.

1. Site Preparation

- A correct installation starts with a proper base.

- The mounting platform must be flat, rigid, and reinforced.

- Avoid installing the shaker on loose or vibrating structures.

- Ensure enough space around the unit for screen replacement, cable routing, and maintenance access.

2. Structural Alignment Requirements

- Correct alignment keeps the shaker running smoothly.

- The shaker bed must be installed horizontally unless manufacturer guidelines specify an angle.

- Check that the vibrator motors are aligned and securely fastened.

- Perform a torque check on all structural bolts.

3. Vibration Isolation Standards

- Install rubber or composite isolation pads under each support point.

- Confirm pads are evenly loaded and not twisted.

- Ensure the shaker doesn’t touch nearby structures during operation.

4. Electrical & Control System Setup

- Electrical work must follow industrial safety codes.

- Use correctly rated cables, breakers, and connectors.

- Ensure all electrical components are sealed and designed for the field environment.

- Verify motor rotation direction before adding mud.

5. Fluid Handling Connections

- Proper fluid connections ensure efficient solids separation.

- Position the feed manifold so drilling mud enters smoothly without splashing.

- Confirm the discharge outlets align with mud tanks or flowlines.

- Avoid restricting the return flow or screen surface.

6. Final Commissioning Standards

- Run the shaker empty to check for abnormal noise or imbalance.

- Confirm screen tensioning is correct and uniform.

- Verify all guards, covers, and safety devices are secured.

Conclusion

Following the correct shale shaker installation standards ensures stable performance, reduces downtime, and supports smooth drilling operations. A proper installation doesn’t just protect the equipment—it helps maintain consistent solids control efficiency and safer site operations.

Key Factors Affecting Shale Shaker Price in Solids Control and Drilling Operations

When selecting solids control equipment, understanding the factors affecting shale shaker price helps buyers make better decisions. A shale shaker plays a crucial role in drilling mud separation, and its cost varies depending on structure, performance level, components, and technical support. Below is a detailed explanation of the main elements that influence pricing in the market.

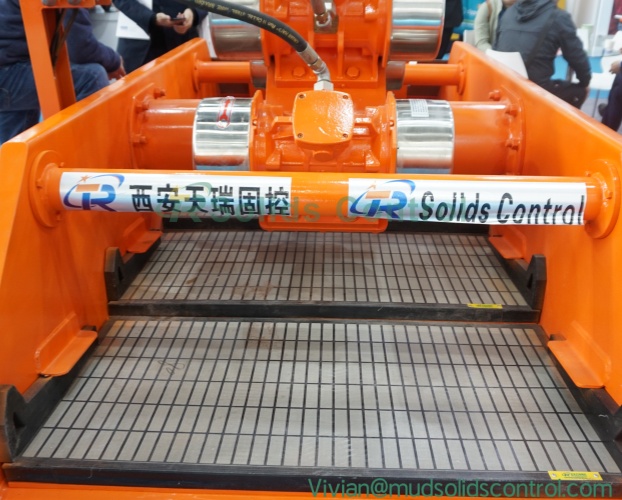

1. Design Type and Motion Mode

Common Designs: Linear motion shale shaker. Balanced elliptical motion shaker

Why it affects price: Linear motion units generally require stronger motors and heavier structures. Elliptical motion units need more precise engineering design.

Shakers with adjustable deck angle, higher G-force, or dual/triple deck configurations increase the price accordingly.

2. Vibration Motor Quality and Power

- Motor brand and origin

- Power rating (e.g., 1.72 kW / 2.2 kW / 2×3.0 kW)

- Protection level (IP55 / IP65 / explosion-proof level)

- Service life and vibration stability

High-quality motors provide stronger vibration, longer operation hours, and lower maintenance cost.

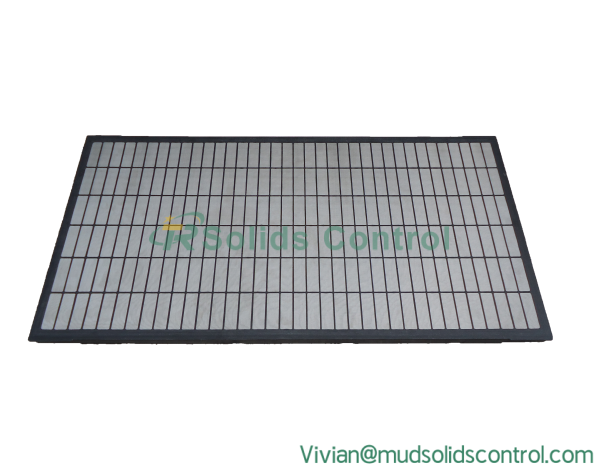

3. Screen Type and Quality

Shaker screens are consumable parts, and their cost directly impacts the overall equipment price.

- Mesh precision

- Frame material

- Layer structure

- API compliance

4. Material and Manufacturing Process

- Carbon steel vs. stainless steel

- Welded vs. laser-cut components

- Rubber springs vs. metal springs

- Coating quality for corrosion resistance

Manufacturers using precision welding, CNC cutting, and high-strength frames will offer more durable shakers but at a higher price range.

5. Processing Capacity and Technical Specifications

Larger and more advanced shale shakers naturally cost more. Bigger capacity means stronger structure and higher power motors, which increases cost.

6. Brand, Service, and Technical Support

Reliable manufacturers offer stronger technical support and spare parts supply. A well-established supplier provides better stability and more professional service, which also reflects in the price.

7. Market Demand and Application Industry

Oilfield-grade equipment often requires higher vibration performance, stronger structure, and better corrosion resistance—leading to higher cost compared to light-duty applications.

Understanding the factors affecting shale shaker price helps buyers choose the right equipment according to their specific needs, application conditions, and budget. Performance, reliability, and long-term maintenance cost should always be considered—not just the initial purchase price.

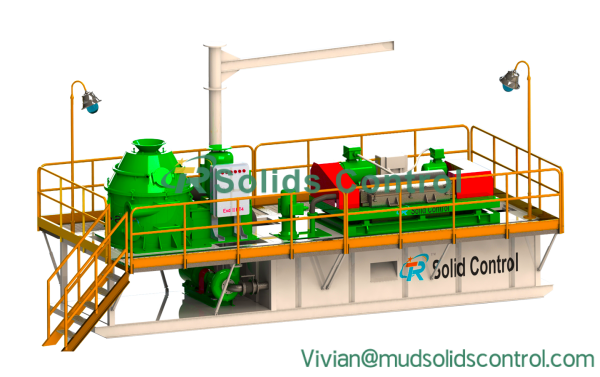

Oil Drilling Waste Management Solutions for Cleaner and More Efficient Operations

In modern oilfield development, effective drilling waste management is key for cleaner, safer, more sustainable operations—it treats/recovers waste like cuttings, residual mud, and contaminated fluids from drilling. China-based manufacturer TR Solids Control (specializing in solids control and waste treatment equipment) offers integrated drilling waste management systems to help oil companies cut environmental impact and operational costs.

1. What Is Oil Drilling Waste Management?

Oil drilling waste management includes a series of processes aimed at separating, drying, and recycling drilling waste. These processes ensure that the discharged materials meet environmental standards while valuable drilling fluid is recovered for reuse.

2. Main Components of a Drilling Waste Management System

A complete oil drilling waste management system typically includes the following equipment:

- Vertical Cutting Dryer: Removes oil or synthetic-based mud from cuttings, achieving efficient drying and recovery of drilling fluids.

- Decanter Centrifuge: Separates fine solids from recovered fluids, improving mud quality and enabling reuse.

- Screw Conveyor: Transfers drilling cuttings from the shale shaker or mud tank to the drying unit automatically.

- Cuttings Collection Box: Stores treated solids for easy handling and safe disposal.

3. Working Principle of TR Waste Management System

When drilling mud and cuttings are discharged from the shale shaker, they are transported by the screw conveyor to the cuttings dryer. The dryer removes excess fluid through high-speed rotation and mechanical separation.

The recovered fluid is then sent to the decanter centrifuge for further purification. After treatment, clean drilling mud can be returned to the active system, while dry solids are collected for safe disposal.

This closed-loop process reduces fluid loss, improves recovery efficiency, and minimizes environmental pollution.

4. Applications of Drilling Waste Management

The drilling waste management system can be applied in various energy projects, including:

- Oil and gas exploration drilling

- Offshore drilling platforms

- Horizontal directional drilling (HDD)

- Coalbed methane (CBM) wells

- Geothermal and mining projects

Its modular design allows flexible configuration according to site layout and project capacity.

5. Conclusion

Effective oil drilling waste management is essential for environmental protection, cost reduction, and operational efficiency. By integrating advanced technologies such as vertical cutting dryers and centrifuges, TR Solids Control helps drilling contractors build sustainable and efficient waste treatment systems.

For cleaner drilling and better resource recovery, TR Solids Control is your reliable partner in oilfield waste management solutions.

Drilling Mud Screening System for Effective Solids Control in Oilfield Operations

In oil and gas drilling, clean, stable drilling mud ensures safe, efficient, eco-friendly operations. The mud screening system—solids control’s first key stage—separates cuttings/large particles from fluid before downstream equipment.China-based supplier TR Solids Control designs/manufactures complete mud screening systems, offering reliable performance, long life, and easy maintenance for on-site fluid recycling.

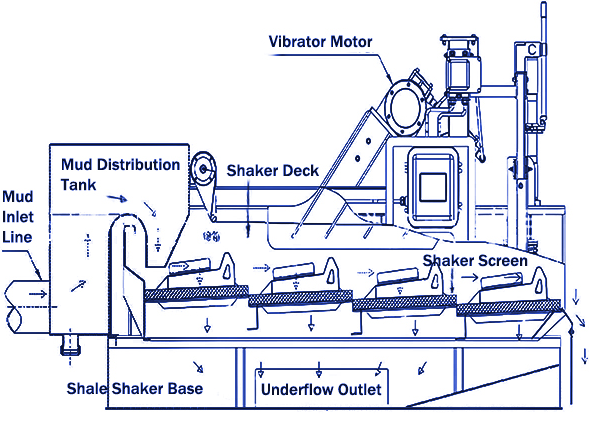

1. What Is a Drilling Mud Screening System?

A drilling mud screening system removes cuttings and solid impurities from mud via mechanical separation. Its core component, the shale shaker, filters solids using high-frequency vibration and fine mesh screens.Cleaned mud then flows to tanks or units like desanders/desilters/centrifuges for further purification, ensuring proper fluid properties, less waste, and protected equipment.

2. Main Components of a Mud Screening System

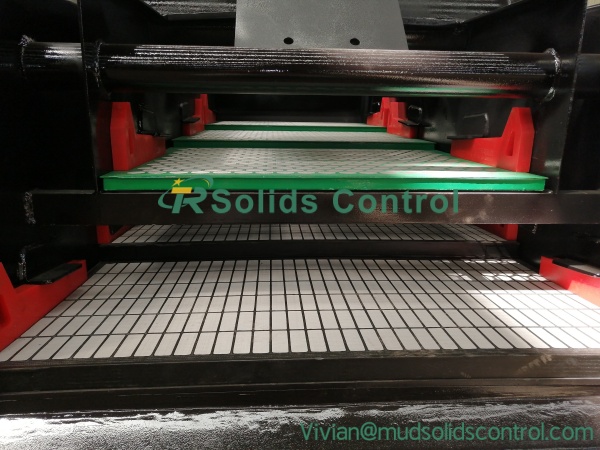

A standard mud screening system from TR Solids Control usually includes:

- Shale Shaker: The first-stage equipment for coarse solids removal.

- Screen Panels: Multi-layer composite mesh screens for effective filtration.

- Feeding Box & Flow Distributor: Directs drilling fluid evenly onto the screen surface.

- Vibration Motors: Provide adjustable G-force for efficient solids separation.

- Mud Tank: Stores screened drilling fluid for reuse.

- Control Panel: Allows operators to adjust vibration frequency and monitor performance.

These components work together to ensure steady mud circulation and continuous solid-liquid separation during drilling.

3. TR Solids Control Mud Screening Systems

TR Solids Control offers several mud screening system models suitable for different drilling projects:

- TRZS703 Linear Motion Shale Shaker System:Capacity: 240 m³/h,|Screens: 3 panels|Adjustable deck angle and vibration force|Ideal for oilfield and HDD projects

- TRZS584 Shale Shaker System:Compact 4-panel design|Flow rate: 130 m³/h|Suitable for small to medium drilling rigs

Each system is customizable based on flow requirements, mud properties, and rig layout. TR also integrates the shakers into complete solids control systems, including desanders, desilters, and centrifuges.

4. Benefits of Using a Mud Screening System

An efficient drilling mud screening system provides multiple operational advantages:

- Maintains optimal drilling mud density and viscosity.

- Reduces wear on pumps and downstream equipment.

- Lowers drilling fluid consumption and disposal cost.

- Improves rate of penetration and drilling stability.

- Promotes environmental compliance by minimizing waste.

With TR Solids Control’s advanced design, operators achieve high separation efficiency and consistent system performance across different drilling conditions.

5. Conclusion

A well-designed drilling mud screening system is essential for any modern drilling operation. It ensures the stability of drilling fluids, enhances safety, and reduces environmental impact.

With reliable equipment, advanced technology, and strong customer service, TR Solids Control remains a trusted partner for global drilling contractors seeking high-performance solids control solutions.

Solids Control Equipment Models Explained – Guide to Efficient Drilling Mud Treatment Systems

In oil and gas drilling, solids control equipment maintains fluid quality and boosts efficiency; understanding its models helps contractors choose the right system for cost-effective performance. China-based professional manufacturer TR Solids Control provides complete solids control systems and various models for reliable drilling mud treatment.

1. Overview of Solids Control System

A complete solids control system is composed of several main units that work together to remove solids from the drilling fluid. The major components include:

- Shale Shaker: The first-stage equipment for coarse solids removal.

- Desander and Desilter: Used for secondary and tertiary separation of fine solids.

- Decanter Centrifuge: Handles ultra-fine particles and ensures clean fluid recycling.

- Vacuum Degasser: Removes gas bubbles from the mud.

- Mud Agitator & Mud Tank: Keep the drilling fluid evenly mixed and stored.

Each of these units has different models designed for specific drilling capacities and mud conditions.

2. TR Solids Control Equipment Models

TR Solids Control provides a wide range of solids control equipment models, covering every stage of mud processing.

- Shale Shaker Models:TRZS703 Linear Motion Shale Shaker:3-panel design, 240 m³/h capacity, suitable for oilfield and HDD projects.TRZS584 Linear Motion Shale Shaker:4-panel design, compact size, efficient solids separation for smaller rigs.

- Desander Models:TRCS250-2S Desander:Equipped with two 10″ hydrocyclones, ideal for medium-capacity mud systems.TRCS300-3S Desander:Larger flow rate, used in high-volume drilling operations.

- Desilter Models:TRCN100-8N Desilter:8 cones (4″), excellent for removing fine solids below 20 microns.TRCN150-12N Desilter:12 cones (4″), higher efficiency for continuous drilling fluid treatment.

- Decanter Centrifuge Models:TRLW355×1250 Centrifuge:Standard oilfield model with adjustable speed and high separation precision.TRLW450×1000 Centrifuge:Compact structure and stable operation for environmental and HDD use.

- Vacuum Degasser Model:TRZCQ270 Vacuum Degasser:Removes entrained gas to protect pumps and improve fluid stability.

3. Choosing the Right Solids Control Equipment Model

Selecting suitable solids control equipment models depends on multiple factors such as:

- Mud properties (viscosity, density, and solids content).

- Drilling depth and rig size.

- Desired flow rate and separation accuracy.

- Available space and installation layout.

TR Solids Control engineers provide professional recommendations and customized system designs to ensure optimal mud processing performance.

4. Advantages of TR Solids Control Equipment

- Durable materials and corrosion-resistant coating.

- Modular design for easy assembly and transport.

- Energy-efficient motors and low noise operation.

- Quick maintenance and convenient spare parts supply.

- Widely used in oilfield drilling, HDD, CBM, and geothermal projects.

Our products have been exported to more than 40 countries, earning recognition for stable quality and competitive pricing.

5. Conclusion

Understanding solids control equipment models is essential for building an efficient and reliable drilling fluid treatment system. Whether you need a high-capacity shale shaker, precision centrifuge, or a complete solids control solution, TR Solids Control provides the right model to meet your operational requirements.

9671640 Screen Frame Weldment for Mongoose Shaker

One of the critical components that contribute to these factors is the 9671640 screen frame weldment.9671640 screen frame weldment highlighting role in enhancing the performance of the Mongoose shaker.

The Mongoose shaker is a vital piece of equipment used in the drilling process to separate solids from drilling fluids.Its efficient design allows for high-capacity processing, making it a preferred choice in various drilling operations.The shaker ensure that the drilling fluid is clean and reusable, which is essential for maintaining operational efficiency and reducing costs.

The Role of the 9671640 Screen Frame Weldment

The 9671640 screen frame weldment is an integral part of the Mongoose shaker. This component serves as the structural backbone that supports the shaker screens. The weldment is designed to withstand the rigors of drilling operations, including exposure to harsh environments and heavy loads. It is robust construction ensures that it can handle the vibrations generated during the shaking process without compromising its integrity.

The 9671640 screen frame weldment is constructed from high-quality materials that are resistant to wear and tear.

The weldment is manufactured with precision to ensure a perfect fit with the Mongoose shaker.

the 9671640 screen frame weldment can be easily installed or replaced.

Designed for compatibility with the Mongoose shaker.

By providing a stable and secure platform for the shaker screens.The 9671640 screen frame weldment contributes to the overall performance of the Mongoose shaker.

Benefits of Using the 9671640 Screen Frame Weldment

The 9671640 screen frame weldment can lead to significant cost savings over time. It is durability reduces the frequency of replacements.9671640 screen frame weldment efficiency enhances the overall productivity of the drilling operation.

screen frame weldment minimizes the risk of equipment failure.

The 9671640 screen frame weldment is a crucial component that enhances reliability of drilling operations. It is durable construction make it an invaluable asset in the oil and gas industry. The 9671640 screen frame weldment a key player in the future of drilling technology.

Contact us today to learn more about SWACO Spring Coil and shaker screens, how TR can support your solids control needs with innovative solutions.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

www.solidscontrolequipment.com

Replacement Derrick Shaker

One of the key components that contributes to this efficiency is the Replacement derrick shaker. Replacement derrick shaker can significantly impact the overall performance of a drilling rig.

Replacement derrick shaker is an essential piece of equipment in the drilling process. Used to separate the drilling fluid from the cuttings produced during the drilling process. Replacement derrick shaker use a series of screens to filter out solid particles, allowing the clean fluid to be reused in drilling operations. This not only saves resources but also improves the overall efficiency of the drilling process.

The necessity of Replacement derrick shaker

When a derrick shaker is inefficient, it can cause several problems, including:

- Increased Downtime.

- Poor Fluid Management.

- Higher Operating Costs.

To mitigate these issues, investing in a replacement derrick shaker is critical. New shakers can restore peak performance, ensuring drilling operations remain efficient and cost-effective.

Select the appropriate replacement derrick shaker

When choosing to replace a derrick shaker, the following factors should be considered:

- Compatibility.

- Performance Specifications.

- Durability.

- Maintenance Requirements.

- Cost Effectiveness.

Advantages of replacement derrick shaker:

- Improved Efficiency: New shakers enhance the separation process, allowing for better fluid management and less waste.

- REDUCED DOWNTIME: With reliable vibrating screens, you can reduce the risk of operational interruptions, resulting in a more consistent drilling schedule.

- Cost Savings: Increased efficiency and reduced downtime mean lower operating costs, making the investment worthwhile.

Replacement derrick shakers can play a key role in achieving this goal. By carefully selecting high-quality alternatives, operators can improve drilling efficiency.This is a strategic move towards long-term success for the drilling industry.

We are an exporter of shaker screen.TR is a Replacement Derrick Shaker maufuacturer and china Hyperpool screen supplier.Our factory approval the API,Drilling Shale Shakers and drilling PMD shaker screen have the API certification.TR solids control is the designed,selling,production,service and delivery of Chinese drilling fluid shakers manufacturers.We will provide the high quality shaker screen and swaco mongoose shaker screen.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:18509252400

E-mail:sales@trsolidscontrol.com