Shale Shaker Screen Types: Understanding the Options for Efficient Solids Control

Choosing the right shale shaker screen types is essential for achieving efficient solids control and stable drilling fluid performance. Different screens vary in structure, material, and mesh configuration, and each screen type serves specific drilling conditions. Understanding these differences helps operators select screens with better durability, separation accuracy, and cost-effectiveness.

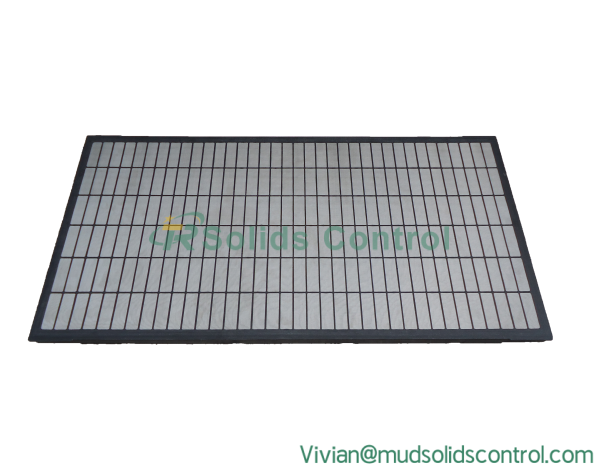

1. Steel Frame Screens

Steel frame screens are widely used due to their sturdy construction.

Features: Strong metal frame; Suitable for high-load operations; Good torsional strength

Best for: Projects requiring strong support and stable performance under heavy solids flow.

2. Composite Frame Screens

Composite screens are becoming increasingly common in modern rigs.

Features: Lightweight composite material; Higher usable mesh area; Better corrosion resistance; Longer lifespan in harsh environments

Best for: Operators seeking improved durability and reduced screen replacement frequency.

3. Hook-Strip Screens

Hook-strip screens are easy to install and replace.

Features: Side-hook connection; Suitable for older shaker models; Cost-effective design

Best for: Rigs using hook-strip tensioning systems or requiring quick screen swaps.

4. Pretensioned Screens

Pretensioned screens offer stable mesh tension and improved separation.

Features: Factory-tensioned mesh; Consistent performance; Compatible with many modern shakers

Best for: Environments where fine solids removal is critical.

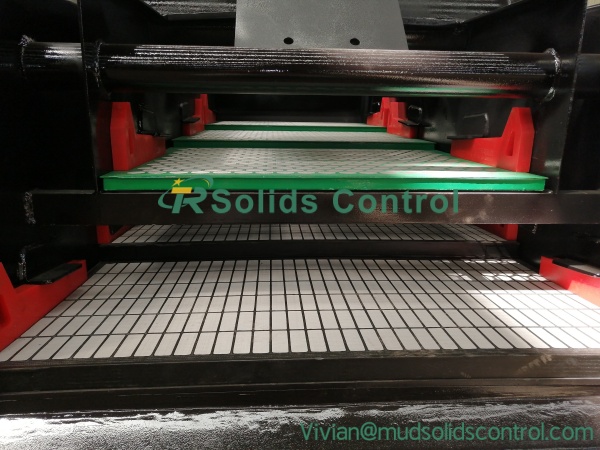

5. Dual-Layer and Triple-Layer Screens

These screens increase screening efficiency with multiple mesh layers.

Features: Multiple fine-mesh layers; Improved cuttings removal; Better handling of fine solids

Best for: Wells with high viscosity mud or fine solid content.

6. Specialty Screens

Some drilling sites require screens engineered for unique conditions.

Common variations include:High-temperature resistant screens; Anti-blocking screens; Corrosion-resistant screens

Best for: Unconventional wells or harsh environments requiring enhanced durability.

Conclusion

Understanding different shale shaker screen types helps drilling teams make informed decisions based on cost, performance, and durability requirements. By choosing appropriate screens—whether composite, steel frame, API-rated, or multi-layer—operators can achieve more stable solids control and reduce operational downtime.

Leave a Reply