Understanding the Working Principle of Shale Shaker in Solids Control Systems

The shale shaker is the first and most important stage of solids control in drilling operations. To ensure stable performance, it is essential to understand the shale shaker working principle, including how vibration force, screen mesh, and motion mode function together to remove solids from drilling mud.

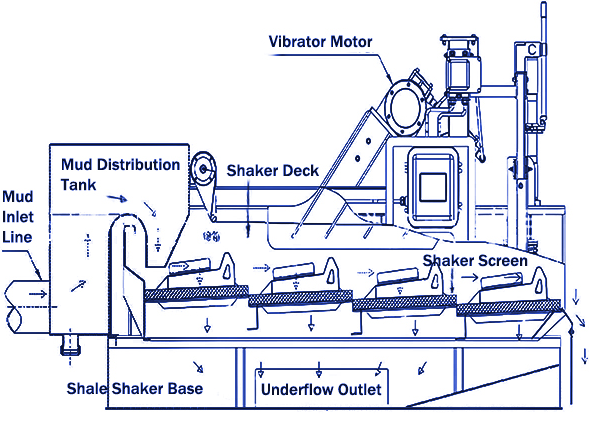

Basic Working Principle of Shale Shaker

The process includes four key steps:

- Vibration Force Generated by Motors: Two vibration motors rotate in opposite directions, producing a strong vibration force. This vibration drives the screen deck to move, conveying cuttings forward and allowing fluid to pass through the mesh.

- Separation Through Screen Mesh: Drilling mud flows onto the screen surface. Liquid phase passes through the screen openings. Solid cuttings are retained and discharged off the shaker deck.

- Conveying of Solids: Under continuous vibration, the cuttings move toward the discharge end. The motion type (linear, elliptical, or circular) affects conveying speed and dryness of cuttings.

- Clean Mud Recycling:After passing through the screen, the cleaned mud flows into the tank below and is reused in drilling operations.

Motion Modes in the Shale Shaker Working Principle

Different shale shakers adopt different vibration motions:

- Linear Motion: Strong vibration force. Fast conveying speed. Suitable for heavy mud and large flow capacity

- Balanced Elliptical Motion: Smooth movement. Better performance for fine screens. Suitable for stable drilling and light mud

Main Components Affecting the Working Principle

- Vibration Motors: Core driving units that generate the required G-force for screening.

- Screen Panels: Available in composite frame or steel frame; mesh size from API 20 to API 325.

- Screen Deck Angle: Adjusting the deck angle changes cuttings dryness and processing capacity.

- Mud Distribution System: Ensures drilling fluid spreads evenly onto the screen surface.

All components work together to achieve efficient separation.

Factors Influencing the Separation Effect

- Screen mesh size and quality

- Vibration G-force

- Deck angle adjustment

- Mud viscosity and density

- Fluid flow rate

The shale shaker working principle is based on vibration-driven screening that efficiently removes solids from drilling mud. By understanding how vibration motors, screens, and motion modes function, operators can improve separation quality and ensure stable drilling operations.

TR Solids Control continues to supply reliable shale shakers with stable performance, advanced structure, and long service life for global customers.

Leave a Reply