Tag Archives: Shale Shaker for Sale

Customized shale shaker manufacturer

Standard shale shakers often fall short of meeting unique operational challenges—such as varying formations, fluid types, or site constraints—that require specialized solutions. Customized shale shakers can be tailored to specific conditions, with adjustments to structural design, material selection, and performance parameters, ensuring an exact fit for each job.

Whether addressing the space limits of offshore platforms, the high solids in shale gas drilling, or the high-temperature demands of geothermal wells, customized shakers resolve the limitations of standard models. TR Solid Control customization service focuses precisely on these requirements, enabling shale shakers to perform more efficiently in fluid purification and cuttings separation.

TR Solid Control offers a full-process customization service, leveraging industry expertise to align closely with specific customer needs from design to delivery.

- Multi-Parameter Adjustment: Customize processing capacity (40‑360 m³/h), vibration mode (linear/elliptical switchable), excitation force, and amplitude based on drilling depth, fluid viscosity, and separation requirements.

- Material & Structure: Screen boxes can be built from Q345B steel or 316L stainless steel for harsh or corrosive conditions. Screen mesh options include polyurethane or high-manganese steel in 20‑200 mesh. Dimensions and layers can be tailored to site constraints.

- Special Features: Options include explosion-proof motors, fully sealed dust‑proof structures, and reinforced damping systems for extreme or sensitive environments.

- Modular Integration: Custom shakers are designed to interface seamlessly with TR full range of solids control equipment (desanders, centrifuges, etc.), forming an efficient, collaborative purification system.

TR Solid Control customized shale shakers provide targeted solutions for diverse drilling challenges.

- Offshore Platforms: Compact, space-saving design with enhanced corrosion resistance for high-humidity, saline environments. Vibration motors feature high protection ratings for reliable operation.

- Shale Gas Horizontal Wells: Optimized elliptical vibration and screen structure improve separation of high-solid-content fluids, reducing chemical usage. Modular design fits confined wellsite spaces.

- Geothermal Drilling: High-temperature materials and seals ensure stable operation from -20°C to +80°C. An optimized cooling system maintains fluid purification under extreme heat.

- Trenchless Engineering: Small, mobile units enable easy transport and setup. Separation parameters are adjustable for various geological conditions in shield tunneling and pipe jacking.

When choosing a customized shale shaker, focus on three key aspects:

- Technical Capability: Ensure the manufacturer can accurately translate your needs into a practical design.

- Material & Craftsmanship: Verify the reliability of materials and build quality for long-term durability.

- After-Sales Support: Confirm the availability of complete post‑delivery service for operation and maintenance.

TR Solid Control provides end-to-end support throughout customization, from site surveys and parameter calculation to solution optimization. We also offer installation guidance, operator training, and a dedicated after‑sales channel for rapid maintenance response.

If you face equipment adaptation challenges in special drilling conditions, consider TR customized shale shaker service. With targeted design, proven quality, and full‑process support, we deliver shakers that match your operational needs and improve drilling efficiency.

Drilling fluid shale shaker wholesale

In large-scale drilling projects for oil, natural gas, shale gas, and the like, multiple drilling fluid shale shakers often need to operate collaboratively, making bulk purchasing the optimal choice for reducing costs and ensuring equipment consistency.

The drilling fluid shale shaker is the core of the solids control system, handling primary purification and cuttings separation. Its stable performance is critical to overall drilling efficiency. When purchasing in bulk, a reputable supplier ensures consistent technical parameters and interchangeable parts across all equipment. This simplifies maintenance, management, and avoids compatibility issues between batches.TR Solids Control Equipment’s bulk service is designed for this purpose, offering full-process support—from product selection and specification matching to logistics and delivery.

TR Solid Control utilizes a mature production system to offer shale shaker wholesale products noted for quality, compatibility, and cost-effectiveness, suitable for drilling projects of any scale.

- Full Specifications: Available in single, double, or triple configurations with capacities from 40–360 m³/h. Features switchable linear/elliptical vibration modes for onshore, offshore, and shale gas operations.

- Standardized Quality: Built to SY/T 5612-2018 and ISO 9001 standards. Features a fully welded Q345B alloy steel screen box with heavy anti-corrosion coating. Core components are 316 stainless steel for harsh-condition durability.

- Adaptable Design: Offers 20–200 mesh screens with quick-release clamps for easy replacement. Screen bed angle adjusts from –2° to +5° to suit varying fluid viscosity and solids content.

- Batch Value: Large-scale production ensures competitive wholesale pricing. Bulk orders come with complete logistics support for fast, multi-region delivery.

TR Solid Control provides wholesale shale shaker services, delivering both high-quality products and professional support for large-scale drilling projects.

- Custom Bulk Solutions: We offer tailored configurations based on your drilling depth, geology, and fluid type, ensuring the equipment matches project needs precisely and prevents resource waste.

- End-to-End Support: This includes free installation guidance, operator training, and a dedicated after-sales channel to ensure prompt resolution of any operational issues.

- Proven Compatibility: Our wholesale products have been deployed in major oilfields across China and exported internationally. They are compatible with onshore, offshore, horizontal, and directional drilling applications.

When purchasing shale shakers in bulk, focus on three core aspects to ensure cost-effectiveness and operational efficiency:

- Supplier Qualifications: Prioritize suppliers with recognized industry certifications and proven large-scale production capabilities.

- Product Consistency: Ensure all equipment has uniform technical parameters, material quality, and component specifications for seamless coordination.

- After‑Sales Service: Verify the supplier’s ability to supply spare parts, provide responsive support, and deliver technical assistance for long-term reliability.

TR Solid Control meets all these criteria. We supply standard‑compliant shale shakers in bulk, reduce costs through customized configurations, and support projects with fast logistics and full‑lifecycle service.

If you are procuring equipment for a large‑scale drilling project, consider TR wholesale service. We provide standardized quality, a full specification range, and cost‑effective supply solutions to ensure solid equipment support for your operation.

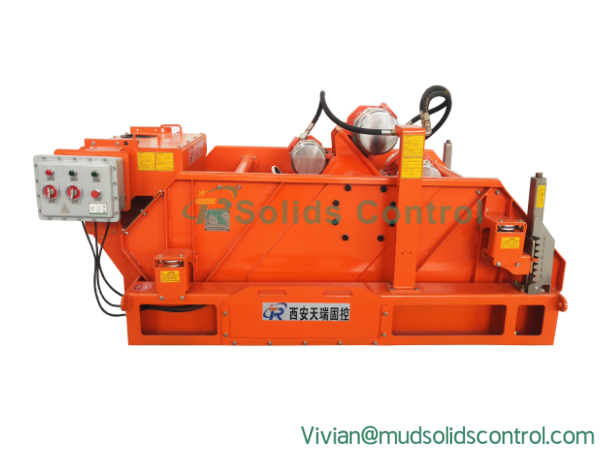

FLC503 Shale shaker Manufacturer

As a professional manufacturer of the FLC503 shale shaker, we are dedicated to providing high-performance mud treatment equipment for the drilling industry. The FLC503 shale shaker, known for its stable screening efficiency and durability, has become a core component of the drilling fluid purification system. When used in conjunction with TR solid control equipment, it enables efficient separation and recovery of drilling fluids, significantly reducing operational costs and meeting environmental protection requirements.

TR solid control, leveraging years of technological experience, enables the FLC503 shale shaker to excel in both performance and practicality, making it suitable for various complex drilling scenarios.

- Stable separation efficiency: Adjustable vibration intensity up to 7.5G—effortlessly separates solids from high-viscosity, high-density drilling fluid, keeping mud performance stable and reliable.

- High durability: High-manganese alloy steel box with full heat treatment and heavy anti-corrosion coating, plus wear-resistant screens and premium international electrical components—built to last under high-intensity drilling conditions.

- Flexible adaptability: -1° to +5° bed angle adjustment & dual linear/elliptical vibration modes—tailored to conventional oil/gas, shale gas drilling, and more, matching any on-site fluid property.

- Easy operation: Wedge-type screen fixation for fast replacement, modular structure for simplified installation and maintenance—cutting your operational costs down effectively.

The FLC503 shale shaker is not operated in isolation, but is an important part of TR’s complete solids control system. It works in coordination with equipment such as desanders, desilters, and centrifuges, forming a multi-stage purification chain to achieve deep processing and recycling of drilling fluids.

Currently, this equipment has been widely used in land oil drilling, offshore drilling, shale gas development, trenchless engineering, and other fields. Whether in high-temperature, high-pressure deep well environments, or in complex, easily collapsible formations, TR’s FLC503 drilling fluid shale shaker can provide continuous and reliable solids control support for drilling operations with its stable performance, helping companies reduce drilling costs and improve operational efficiency.

When choosing shale shaker, in addition to paying attention to separation efficiency and durability, the equipment compatibility, ease of maintenance, and the manufacturers technical strength are equally important. As a professional provider of solid control system solutions, TR Solid Control not only offers high-quality FLC503 shale shaker models but can also provide customized designs and comprehensive after-sales services based on customer needs. From equipment selection and installation to commissioning and later maintenance, TR Solid Control ensures full support for drilling operations.

If you are looking for an efficient and reliable shale shaker solution for your drilling projects, the FLC503 model from TR Solid Control is worth considering. It combines advanced design concepts with practical technical features, making it a reliable piece of equipment in drilling solid control systems.

Shale Shaker: The Core of Efficient Solids Control

In oil and gas drilling, the shale shaker is the core of an efficient solids control system, performing the critical function of separating large solid particles from drilling fluid and supplying clean liquid to downstream mud treatment equipment. As the indispensable first line of defense in the solids control workflow, it safeguards drilling fluid quality, boosts operational efficiency, and cuts costs.

A professional solids control equipment manufacturer, TR Solids Control offers a full range of shale shakers—including linear and elliptical models—to meet the demands of diverse drilling projects. With precision engineering and stable performance, TR shale shakers deliver high-efficiency solid-liquid separation, providing dependable support for oil and gas drilling operations.

Shale shakers are the first equipment in a solids control system, primarily used for primary solid-liquid separation of drilling fluid. Their working principle is that a vibration motor generates vibrations, allowing drilling fluid to pass through the screen and separating out large solid particles. Their main functions include:

- Improving solids control efficiency: The Shale Shaker efficiently removes cuttings and solid particles from the drilling fluid, reducing the treatment load of subsequent equipment.

- Extending the lifespan of the mud: By effectively separating solid materials, the Shale Shaker can reduce drilling fluid consumption and improve the recycling efficiency of the mud.

- Optimizing downstream processing: The cleaned liquid phase enters downstream equipment, such as desanders and centrifuges, ensuring smooth subsequent processing.

The Shale Shaker provided by TR Solid Control Equipment performs excellently in drilling solid control systems. Here are several prominent advantages of TR Solid Control Equipment:

- High Stability: The Shale Shaker of TR Solid Control Equipment is designed with a focus on stability, ensuring continuous operation in high-intensity working environments.

- Efficient Separation: Whether it is a linear vibrating screen or an elliptical vibrating screen, the Shale Shaker from TR Solid Control Equipment can efficiently separate large solid particles from drilling fluid, ensuring stable mud performance.

- Long Service Life: The Shale Shaker of TR Solid Control Equipment is equipped with wear-resistant screens, capable of operating stably over a long period under high-intensity drilling operations.

- Strong Adaptability: TR Solid Control Equipment offers various models of Shale Shakers to meet different working conditions according to different drilling fluid characteristics and drilling environments.

The application of Shale Shakers in the oil and gas industry is very extensive, including but not limited to the following areas:

- Conventional oil and gas drilling: Shale Shakers are essential equipment in traditional drilling operations.

- Shale gas drilling: Shale Shakers can efficiently separate solid particles from drilling fluids, maintain fluid properties, and adapt to complex shale gas drilling operations.

- Deepwater drilling: TR solid control equipment’s Shale Shakers can operate stably in high-pressure, high-flow deepwater drilling environments, ensuring efficient circulation of drilling fluids.

The shale shaker is an indispensable core component of drilling solid control systems. It efficiently separates solids from drilling fluid, delivering a stable liquid supply for downstream mud treatment equipment. TR Solids Control provides high-efficiency, stable shale shaker products that are widely used in oil and gas drilling operations globally, offering customers reliable solid control solutions.

Shale Shaker Applications in Oil and Gas Industry

Shale shakers are key components of drilling solids control systems. As drilling equipment, they are mainly used for solid-liquid separation of drilling mud in oil and gas drilling processes—separating cuttings and recovering reusable drilling fluid to ensure continuous, stable drilling operations. In modern oil and gas drilling engineering, proper use of shale shakers has become a crucial way to improve the operational efficiency of solids control systems.

In oil and gas drilling operations, drilling mud carries a large amount of cuttings back to the surface. As a primary solid control device, the shale shaker mainly performs the following tasks:

- – Separates large solid particles from the drilling fluid

- – Reduces the workload of subsequent desanders and desilters

- – Minimizes mud loss and improves recycling efficiency

- – Helps stabilize mud properties and protect drilling equipment

With a smoothly operating shale shaker system, the mud system at an oil and gas drilling site can be kept clean and balanced.

The application of shale shakers in the oil and gas industry covers multiple operational scenarios:

- Onshore oil and gas drilling – Shale shakers are used in conventional oil and gas wells, shale gas wells, and other drilling operations, adapting to drilling fluids of different densities and flow rates.

- Offshore drilling platforms – Shale shakers feature a compact structure and stable operation, making them suitable for offshore drilling environments with limited space.

- Unconventional energy development – During shale oil and shale gas drilling, there is a higher requirement for fine particle separation, and the shaker screen configurations are more flexible.

In practical oil and gas industry applications, the operational performance of a Shale Shaker is affected by various factors:

- – Vibration mode (linear motion, elliptical motion)

- – Selection of screen mesh size and material

- – Configuration of the vibrating motor’s excitation force

- – Drilling mud flow rate and viscosity

- – Equipment installation angle and maintenance condition

Proper selection and standardized operation help to maximize the value of the shaker in oil and gas drilling applications.

As a professional solid control equipment supplier in China, TR Solid Control has long provided shale shakers and supporting solutions for oil and gas drilling projects. TR’s Shale Shaker products focus on:

- – Stable vibration system structure

- – Compatibility with multiple screen specifications

- – Convenient screen replacement methods

- – Operation adaptability for different working conditions

TR Solid Control has been widely used in oil and gas drilling and mud treatment systems, helping customers achieve stable and efficient solid control operations.

With the continuous development of oil and gas drilling technology, the application of Shale Shakers in the oil and gas industry is also showing new trends:

- – Shaker designs with higher processing capacity

- – More wear-resistant screens with longer service life

- – Equipment solutions that focus more on energy saving and environmental protection

- – Collaborative application with automated solids control systems

These trends are driving the continuous optimization and upgrading of shaker applications in the oil and gas industry.

Overall, the application of shale shakers in the oil and gas industry is of great significance for drilling mud treatment and the operation of solids control systems. By reasonably selecting shaker equipment and applying it according to actual working conditions, oil and gas drilling projects can achieve more stable mud circulation and more efficient solids control management. TR solids control equipment will continue to provide reliable shale shakers and supporting solutions for the oil and gas industry.

Drilling Shale Shaker: Applications and Value in Oil-Gas Solids Control

In the process of oil and gas exploration and development, the Drilling Shale Shaker is one of the core pieces of equipment in the drilling solids control system, mainly used for the primary solid-liquid separation of drilling fluid. Through high-frequency vibration and screen filtration, the shaker can effectively separate cuttings and maintain the stability of the drilling fluid.

The Drilling Shale Shaker provided by TR Solids Control is widely used in various types of drilling projects due to its reasonable structural design, stable operation, and adaptability to different working conditions.

Basic working principle of a Shale Shaker: Regular vibrations are generated by a vibrating motor, causing the drilling fluid to form a flow path on the screen surface: drilling fluid passes smoothly through the screen for recovery; solid particles are retained and quickly discharged; reduces the sand content in the drilling fluid; improves the operating conditions of subsequent solids control equipment.

TR Solids Control in the design and application of Drilling Shale Shakers, focuses on equipment stability and practicality, mainly reflected in:

– Multiple mesh configurations to adapt to different drilling fluid systems

– Dual motors or linear vibration structures to ensure screening efficiency

– Adjustable screen box angles to meet different flow and viscosity requirements

– Modular structural design for easy on-site maintenance and replacement

Application Scenarios of Drilling Shale Shaker in Drilling Solid Control Systems

Onshore oil and gas drilling projects

Offshore platform drilling projects

Directional and horizontal well operations

High-circulation drilling fluid handling systems

By properly configuring the Drilling Shale Shaker, the overall efficiency of the solid control system can be effectively improved.

How to Choose the Right Drilling Shale Shaker?

When selecting a model, you can focus on the following factors:

– Drilling fluid handling capacity and flow requirements

– Screen size and ease of replacement

– Vibration type and excitation force parameters

– Stability of continuous equipment operation

– Manufacturer’s technical support and service capabilities

TR solid control equipment can provide various models of Drilling Shale Shakers according to different drilling conditions, meeting the diverse needs of projects.

As an important component of the drilling solid control system, the Drilling Shale Shaker plays a crucial role in ensuring the quality of drilling fluid, reducing equipment load, and improving operational efficiency. With the application experience of TR solid control equipment, it can provide more stable and sustainable solid control solutions for oil and gas drilling projects.

M-I SWACO Shakers: Reliable Drilling Solids Control

M-I SWACO Shakers are a staple in the drilling industry, delivering reliable solids separation for onshore, offshore, and geothermal projects. As a vital part of mud management systems, they separate cuttings from drilling fluid, preserve fluid properties, and support operational efficiency and environmental compliance. Valued for adaptability across diverse drilling conditions, these shakers require compatible, high-performance complementary or replacement equipment—and TR Solids Control provides engineered solutions that meet industry standards and integrate seamlessly with M-I SWACO systems.

M-I SWACO Shakers deliver robust, consistent performance that underpins effective solids control workflows. Leveraging precision vibration technology and durable screens, they efficiently remove cuttings of all sizes—from fine sand to coarse rock—maintaining drilling mud viscosity and cleanliness for optimal operations. Whether as a primary separator or part of a multi-stage system, these shakers reduce downtime, cut operational costs, and minimize environmental impact, making them a globally popular choice for drilling projects.

Compatibility is critical for operators upgrading solids control setups or replacing aging units—and TR Solids Control delivers fully compatible shale shakers for M-I SWACO systems. Every component—frame dimensions, vibration frequency, screen mounts, and fluid flow paths—is engineered to match M-I SWACO specifications, ensuring seamless integration without costly rig modifications. Whether expanding fleets or replacing worn units, TR’s solutions offer the same reliability and performance M-I SWACO Shakers are known for.

Beyond compatibility, TR Solids Control shale shakers embody the durability and adaptability central to quality solids control equipment. Built with high-strength materials for harsh drilling conditions, they feature premium vibration motors for stable performance and a range of screen options to handle diverse drilling fluids and cuttings sizes. Maintenance-friendly design—with accessible components and quick-release screen mechanisms—minimizes routine downtime, keeping drilling operations on track.

TR Solids Control compatibility focus goes beyond hardware: its team collaborates closely with clients to address operational needs—from high-volume offshore rigs to small-scale onshore projects using M-I SWACO Shakers. This client-centric approach tailors each compatible shale shaker to unique demands, such as corrosive fluids or extreme temperatures. Plus, comprehensive technical support for installation, calibration, and troubleshooting helps operators maximize integrated solids control system performance.

In an industry where efficiency and reliability are paramount, M-I SWACO Shakers are trusted solids control solutions. For operators looking to extend their system value or source reliable replacements, TR Solids Control delivers fully compatible shale shakers—precision-engineered, durable, and client-focused—to ensure seamless integration, consistent performance, and cost-effective, compliant drilling operations.

To sum up, M-I SWACO Shakers remain a cornerstone of effective solids control in drilling, and TR Solids Control has the capability to produce shale shakers that are completely with these systems. Whether you’re looking to expand your solids control fleet, replace outdated equipment, or optimize your existing setup, TR Solids Control compatible shale shakers offer a reliable, seamless solution that aligns with the performance and specifications of M-I SWACO Shakers.

Mud Shale Shaker for Efficient Drilling Solids Control

Mud shale shakers are the first and most critical link in drilling mud solids control systems: they separate cuttings from drilling fluid, maintain mud properties, and ensure smooth drilling operations. Well-designed units directly impact efficiency, cost management, and environmental compliance across onshore, offshore, and geothermal projects—making a trusted supplier a key choice for drilling contractors prioritizing stable performance.

Effective solids control relies on precision-engineered mud shale shakers—and TR Solids Control is a leading provider of customized solutions in this space. Our shakers prioritize durability and separation accuracy, boasting a high-strength steel frame for harsh drilling conditions and premium vibration motors for stable, optimal cuttings removal. With a range of screen sizes to handle diverse fluids and cuttings (from fine sand to coarse rock), they ensure drilling mud meets your exact operational standards.

A key advantage of TR Solids Control’s mud shale shakers is their exceptional adaptability to diverse drilling scenarios. Configurable with dual/triple decks for high-volume operations enabling uninterrupted mud recovery and available as compact modular units for space-constrained sites offshore platforms, compact onshore locations, they retain full functionality while maximizing efficiency. Plus, hassle-free maintenance features—quick-release screen clamping and accessible lubrication points—minimize downtime.

Beyond top-tier hardware, TR Solids Control offers comprehensive technical support for its mud shale shakers. Our team partners closely with clients to address unique drilling challenges—high-temperature wells, corrosive fluids, remote sites—and recommends tailored configurations. This customer-centric approach ensures each shaker meets industry standards and project-specific needs, delivering lasting value and reliable performance.

In today’s competitive oilfield industry, efficient drilling mud recovery is critical. High-quality mud shale shakers reduce fresh mud purchases, cut waste disposal costs, and support environmental compliance by minimizing contaminated fluid discharge. Committed to innovation, TR Solids Control equips its shakers with the latest vibration technology and material science advances to deliver consistent, high-performance solids separation.

Whether you’re upgrading an existing solids control system or outfitting a brand-new drilling project, TR Solids Control’s mud shale shakers deliver the reliability, efficiency, and adaptability needed to support your operational goals.

With a focus on quality engineering and close customer collaboration, TR remains a trusted partner for drilling professionals who depend on high-performance mud shakers to get the job done right—especially when it matters most.

Shale Shaker for Sale: How to Choose the Right Model for Your Drilling Needs

If you are searching for a dependable shale shaker for sale, understanding key selection factors can help you choose equipment that supports efficient drilling mud treatment. The shale shaker plays a crucial role in removing solids from drilling fluids, reducing equipment wear and improving overall rig performance. Many operators worldwide also consider solutions from TR Solids Control, a recognized supplier of solids control equipment.

What the Shale Shaker Does in Drilling Operations

The shale shaker is the first-stage solids control device on a drilling rig. Its main functions include:

- Separating large drilled cuttings from circulating mud

- Maintaining stable mud viscosity and density

- Protecting downstream equipment such as desanders, centrifuges, and pumps

- Reducing operational costs by recycling usable drilling fluid

When comparing shale shaker for sale options, mud processing efficiency and screen compatibility are essential considerations.

Key Factors to Consider When Choosing Shale Shaker for Sale

- Vibration Mode (Linear or Elliptical Motion): Different vibration modes deliver different performance: ①Linear motion: suitable for heavy loading and high flow rates. ②Balanced elliptical motion: smoother operation and energy-efficient. Choose the mode according to drilling conditions and solids loading.

- Screen Type & API Rating: Screen quality greatly affects separation efficiency. Check for: ①API RP 13C compliance②Mesh size options③Screen frame material (plastic, composite, steel)④Screen longevity. TR Solids Control provides a wide range of API-certified screens compatible with many shaker models.

- Processing Capacity: Capacity should match rig size and expected solids volume. Typical parameters include: ①Flow rate ②Screen area ③G-force. These determine how effectively the shaker manages heavy drilling loads.

- Structure & Maintenance Convenience: Look for: ①Quick screen replacement systems ②Durable vibration motors ③Corrosion-resistant materials ④Easy access for routine maintenance. A well-designed shale shaker reduces downtime and maintenance costs.

Where to Find Shale Shaker for Sale

When searching for a shale shaker for sale, compare suppliers based on:

- Product specifications and performance

- Service support and spare parts supply

- Customizable design options

- Delivery capability and industry experience

TR Solids Control offers global supply and technical assistance, making it a reliable choice for many drilling contractors.

Why Many Operators Choose TR Solids Control

TR Solids Control produces a range of shale shakers known for:

- Stable performance

- API-compliant screens

- Durable structural design

- Flexible customization for different rigs

Whether you need linear motion shakers, dual-shaker systems, or high-capacity units, TR provides practical solutions for various oilfield environments.

Choosing the right shale shaker for sale requires careful evaluation of vibration mode, screen type, capacity, and structural durability. By partnering with a trusted manufacturer such as TR Solids Control, drilling operations can benefit from stable mud treatment and improved cost efficiency.

Shale Shakers: Key Functions in Drilling Rig Mud Systems

The shale shaker in drilling rig mud systems is the primary solids control device responsible for removing drill cuttings from the circulating drilling fluid. As the first-stage separation equipment, the shale shaker ensures stable mud performance, protects downstream machinery, and supports continuous drilling operations. Its working efficiency directly affects drilling safety, equipment service life, and overall mud cost.

What Is the Shale Shaker in Drilling Rig

At its core, the drilling rig shale shaker is a mechanical screener that removes large/medium drill cuttings (rock, shale, formation debris) from drilling mud. Drilling fluid cools/lubricates the drill bit, transports cuttings to the surface, and maintains pressure to block formation fluids—contamination from unseparated cuttings reduces its viscosity and impairs these critical functions.

Working Process of Shale Shaker in Drilling Rig

The shale shaker operates on a simple yet highly effective principle: Drilling fluid mixed with cuttings is pumped to the surface and fed onto a vibrating screen (mounted on a frame driven by electric/hydraulic motors at specific frequency and amplitude). Vibration moves cuttings across the screen—larger particles are discharged as waste, while cleaned fluid passes through and re-enters the mud system for reuse.

Core Functions of Shale Shaker in Drilling Rig Operations

- Protecting Drilling Fluid Quality: A high-performance shale shaker removes most solid particles before fluid reaches downstream equipment, reducing their workload, preserving fluid chemical properties, extending fluid lifespan, and cutting replacement costs.

- Enhancing Drilling Efficiency: Clean drilling fluid maintains optimal density and viscosity for pumping and cuttings transport. By preventing drill bit overheating/clogging, the shale shaker enables faster penetration rates and shorter drilling cycles.

- Ensuring Operational Safety: Consistent fluid density (maintained via effective solids separation) preserves required pressure for well control, mitigating blowout risks from contaminated fluid-induced pressure loss.

- Reducing Environmental Impact: Efficient solids separation minimizes contaminated fluid disposal volume, lowering waste management costs. Reusable treated fluid and responsible solid waste handling reduce the drilling operation’s environmental footprint.

Why Shale Shaker Is Essential in Rig Mud Systems

- Controls Solids Content: Removing solids reduces mud density and viscosity, ensuring efficient drilling.

- Protects Downstream Equipment: Hydrocyclones, centrifuges, and pumps work more efficiently with cleaner mud.

- Improves Drilling Safety: Stable mud properties maintain wellbore pressure and prevent drilling hazards.

- Reduces Operational Costs: Cleaner mud extends screen life, reduces chemical usage, and lowers disposal volume.

How to Select Shale Shaker for Drilling Rig

- Required processing capacity

- Motion mode (linear or elliptical)

- API screen size compatibility

- Vibration G-force

- Screen replacement system

- Rig space limitations

The well-selected shale shaker enhances entire mud system efficiency and reduces downtime.

The shale shaker in drilling rig operations plays a vital role in solids control and drilling mud management. By efficiently removing cuttings, it supports clean mud circulation, reduces equipment wear, and ensures smooth and cost-effective drilling. With the right design and proper maintenance, a shale shaker significantly improves rig performance and operational stability.