Tag Archives: shaker screen manufacturer

A Complete Guide to Shale Shaker Screen Replacement for Drilling Operations

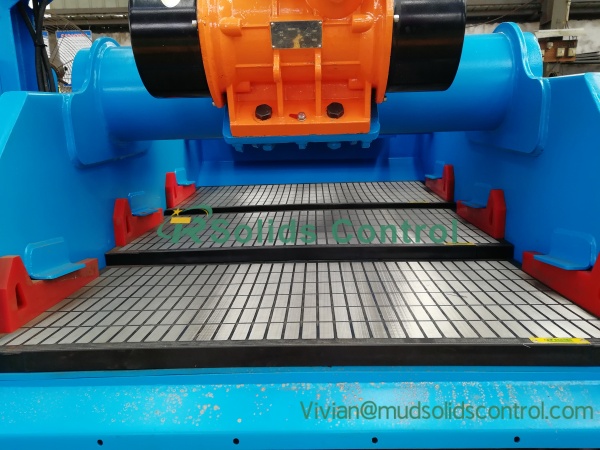

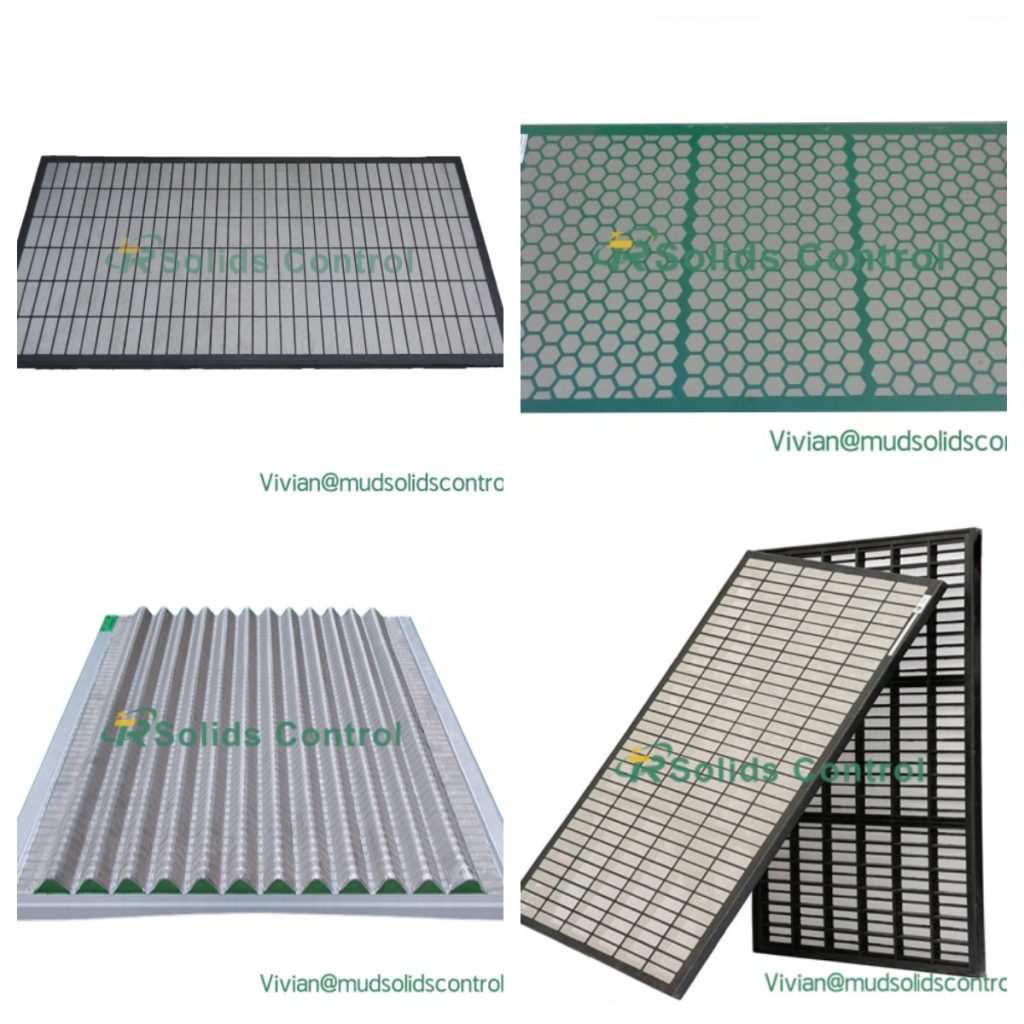

Efficient solids control begins with well-maintained shale shakers — the first line of defense in the drilling fluid process. Among all components, the shale shaker screen is the most critical and frequently replaced part. Timely shale shaker screen replacement ensures stable operation, clean drilling mud, and reduced wear on downstream equipment.

For drilling contractors, knowing when and how to replace screens can prevent costly downtime and improve the overall performance of the solids control system.

1.Regular screen replacement is essential because it:

- Maintains optimal screening efficiency and fluid recovery.

- Prevents contamination of drilling mud.

- Reduces equipment stress and vibration load.

- Lowers overall operation costs by avoiding damage to the shaker deck.

A damaged or clogged screen can quickly affect the performance of the entire mud system, making preventive replacement a necessary maintenance step.

2. When Should You Replace a Shale Shaker Screen?

Recognizing the right time for shale shaker screen replacement can save both time and money. Common indicators include:

- Noticeable fluid loss or overflow on the shaker deck.

- Tears or holes visible in the screen mesh.

- Reduced separation performance, with more solids in the returned mud.

- Abnormal vibration or noise during operation.

- Excessive blinding or plugging that cannot be cleaned effectively.

Replacing the screen before complete failure helps maintain system efficiency and prevents unplanned downtime.

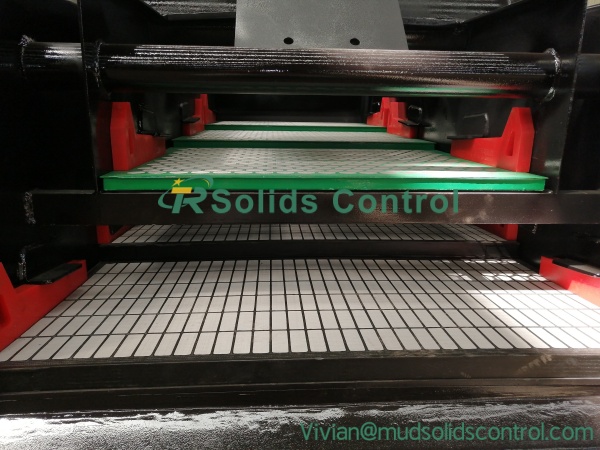

3. How to Replace a Shale Shaker Screen: Step-by-Step Process

- Stop the machine and disconnect power: Ensure all vibration motors are turned off and the system is depressurized.

- Remove worn screens: Release the tensioning assemblies or wedges carefully to avoid damage to the frame.

- Clean the shaker deck and frame: Wipe down the screen bed to remove mud and residue before installation.

- Install new screens: Place new screens securely and align them properly. Tighten clamps or wedges to achieve uniform tension.

- Check seals and gaskets: Ensure all sealing surfaces are intact to prevent mud leakage.

- Restart and test: Gradually restart the shaker and inspect for even vibration and no fluid bypassing.

Following the correct procedure ensures optimal performance and prolongs screen life.

4. Maintenance Tips for Extending Screen Life

- Clean screens regularly using soft brushes or water (avoid high pressure).

- Avoid dropping heavy tools or cuttings onto the screen surface.

- Maintain proper vibration settings and deck angle.

- Store spare screens flat and dry to prevent corrosion or warping.

- Inspect screens daily and replace them at the first sign of damage.

Following these tips ensures consistent mud separation efficiency and longer equipment lifespan.

5. Conclusion

Timely shale shaker screen replacement is essential for maintaining drilling efficiency and protecting your solids control system. Using high-quality screens, following the correct replacement process, and working with a trusted supplier will help reduce downtime and extend equipment life.

As a professional manufacturer, TR Solids Control offers reliable shaker screens and full after-sales support — helping oilfield operators achieve efficient, clean, and sustainable drilling performance worldwide.