Tag Archives: Screen Selection

Maximizing Shaker Performance: A Guide to Screen Selection and Optimization

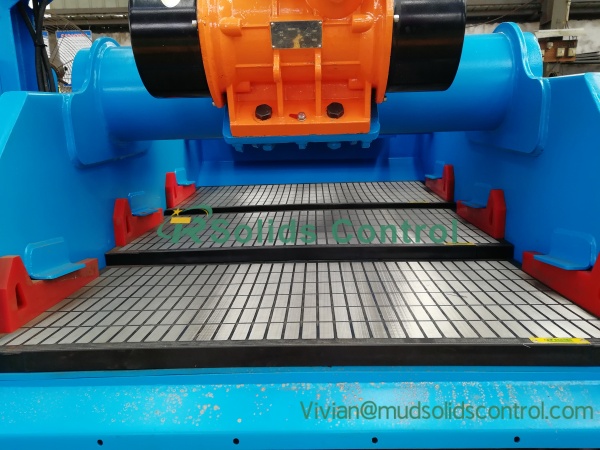

In the critical world of drilling fluids management, maximizing shaker performance is the non-negotiable first step to achieving efficient solids control. The heart of this process lies in effective shaker screen selection, a decision that directly impacts everything from drilling fluid cleanliness to operational cost. Choosing the wrong screen can lead to lost fluid, screen blinding, and excessive downtime, while the right choice ensures optimal separation, protects downstream equipment, and keeps your project on budget. This guide will walk you through the key factors to consider for shaker screen selection and how to optimize their operation for peak efficiency.

How to Select the Right Shaker Screen

The goal is to find a screen that removes the maximum amount of damaging solids without losing valuable drilling fluid.

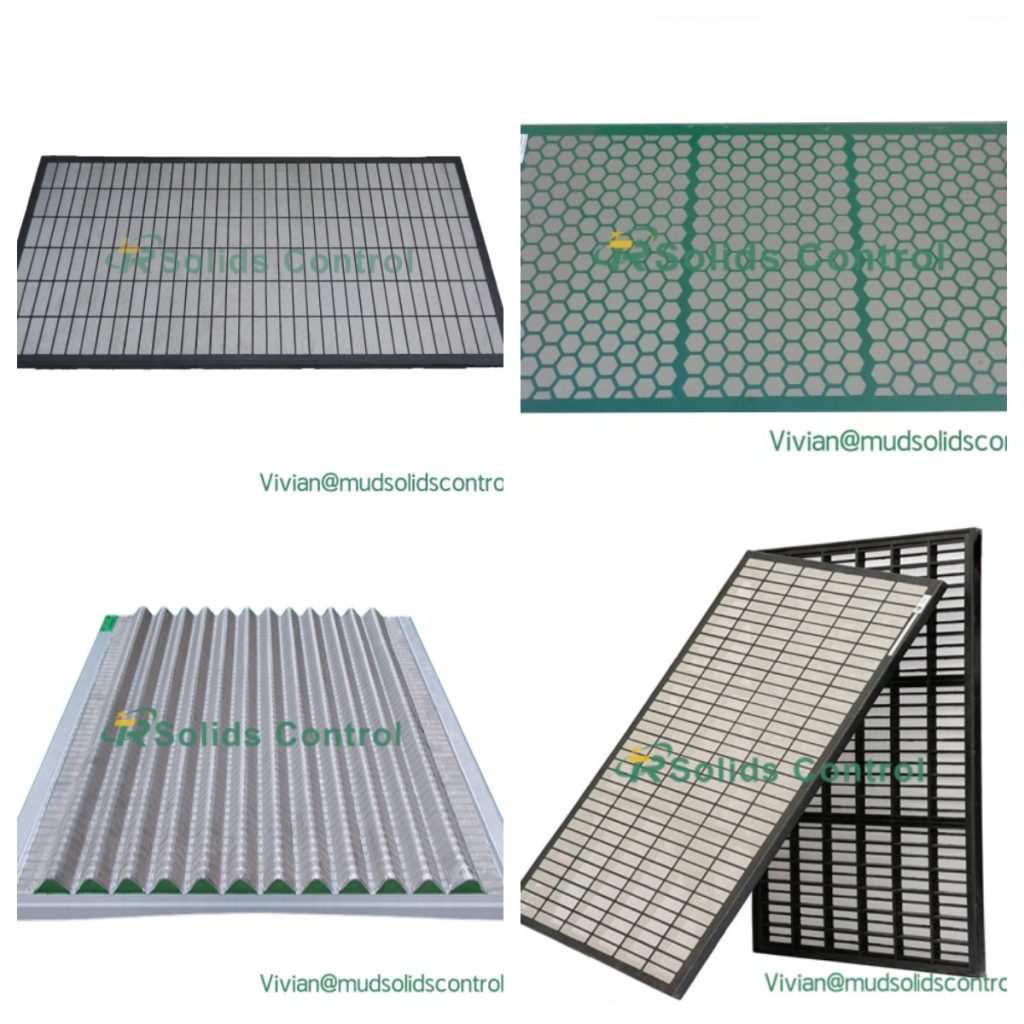

Match the Micron Rating to Your Drilling Phase: Use a coarser screen (higher micron rating) during top-hole drilling where large solids are prevalent. Move to finer screens (lower micron rating) as you drill deeper to remove finer, abrasive solids.

Consider Your Drilling Fluid Properties: The viscosity and flow rate of your mud affect screen performance. Heavier, high-viscosity fluids may require a coarser screen or one with a larger non-blanking area to prevent plugging.

Optimizing Your Screen’s Performance

Selection is only half the battle. Proper operation is key to optimize shaker screens.

Check Tension Frequently: A loose screen will “deadhead” and lose efficiency, causing fluid to bypass the screening process. Re-tension screens regularly according to the manufacturer’s instructions.

Monitor for Blinding: If the screen appears coated with a layer of mud, it’s blinded. This is often caused by sticky clays or high fluid loss. Adjust fluid properties or consider a screen with an anti-blinding coating.

Manage Fluid Flow: Ensure the flow is evenly distributed across the entire width of the screen. A concentrated flow can quickly overload and damage one section, leading to premature failure.

Conclusion: Performance is a Choice

There is no single “best” shaker screen. The right choice is a deliberate balance between your specific drilling conditions, fluid properties, and performance goals. By mastering the principles of shaker screen selection and committing to regular maintenance and optimization, you can significantly maximize shaker performance. This proactive approach directly translates to reduced drilling costs, longer equipment life, and a smoother, more efficient operation from top hole to total depth.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/h