Tag Archives: frame shale shaker screen

Shaker Screen Selection: Key to Drilling Screening Efficiency

In drilling solids control, the shale shaker screen is the essential consumable that determines separation precision, fluid-treatment efficiency, and overall shaker reliability. Choosing the wrong screen can cause rapid wear, fluid loss, or reduced purification-raising operational costs.

TR Solids Control supplies a full range of screens tailored to different drilling conditions and fluid properties, and provides a systematic selection method to help operators match the screen precisely to their on-site needs.

Choosing the right screen involves balancing several key factors based on drilling conditions:

- Mesh Size: Larger mesh (20-60) handles high‑flow, coarse cuttings. Medium mesh (80-120) suits routine fluid purification. Fine mesh (150-200) is for precise separation in shale gas or tight oil drilling.

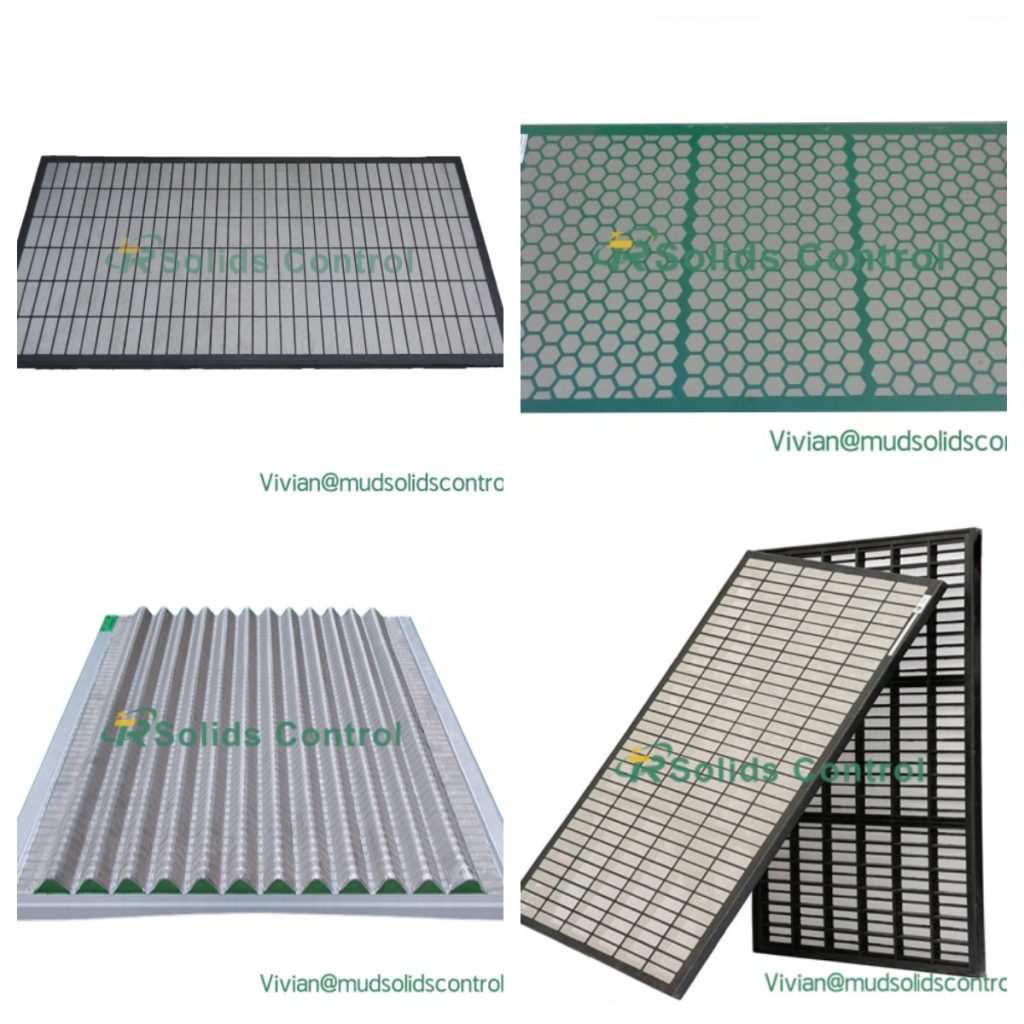

- Material for Fluid Properties: Polyester: cost-effective for standard water-based fluids. Polyurethane: wear- and clog-resistant for high-viscosity, high-solids mud. 316L stainless steel: for corrosive conditions (e.g., salt-cement or acidic fluids).

- Dimensions & Mounting: Screen size and fastener positions must match your specific shaker model.

- Structure for Operational Intensity: Multi-layer composite screens (coarse base + fine top) withstand continuous, high-intensity vibration. Single-layer screens are adequate for intermittent or lighter operations, helping control costs.

TR Solids Control offers a comprehensive range of screen panels in polyurethane, polyester, and 316L stainless steel, covering 20-200 mesh and sized for all single, double, and triple shaker models. Custom screens are available for specialized drilling conditions.

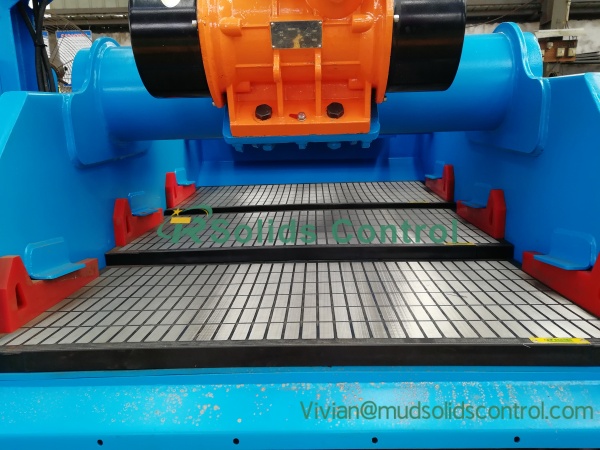

Our screens are designed for precise fit, tension, and flatness on shakers, reducing fluid pooling and improving separation efficiency. The quick‑release snap design allows tool-free, one-person replacement, cutting maintenance downtime.

TR Solids Control provides full support to help you select the right shaker screens without guesswork.

- Professional Selection Guidance: Our technical team will recommend the best screen material, mesh size, and specs based on your drilling conditions, fluid type, cuttings size, and shaker model.

- On-Site Compatibility Testing: For complex conditions, we can perform on-site trials with different screens to evaluate performance and efficiency, ensuring the optimal choice.

- Operator Training: We train your on-site staff in screen selection and replacement methods, empowering them to adapt to changing conditions independently.

Screens selection may seem minor, but it directly affects screening efficiency, drilling fluid quality, and overall solids control performance. TR Solids Control not only supplies a full range of high-quality mesh products but also provides scientific selection methods and full technical support based on professional expertise and field experience. This ensures each mesh choice precisely matches drilling conditions, supporting efficient, stable cuttings separation and fluid purification to help reduce costs and improve drilling-process efficiency.