Tag Archives: Dual-Deck Shale Shaker

FLC503 Shale shaker Manufacturer

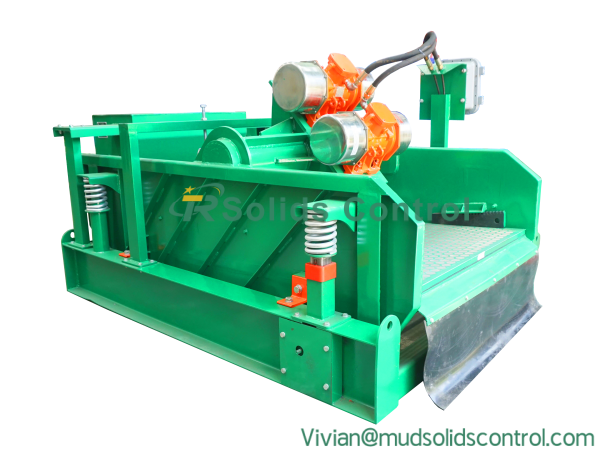

As a professional manufacturer of the FLC503 shale shaker, we are dedicated to providing high-performance mud treatment equipment for the drilling industry. The FLC503 shale shaker, known for its stable screening efficiency and durability, has become a core component of the drilling fluid purification system. When used in conjunction with TR solid control equipment, it enables efficient separation and recovery of drilling fluids, significantly reducing operational costs and meeting environmental protection requirements.

TR solid control, leveraging years of technological experience, enables the FLC503 shale shaker to excel in both performance and practicality, making it suitable for various complex drilling scenarios.

- Stable separation efficiency: Adjustable vibration intensity up to 7.5G—effortlessly separates solids from high-viscosity, high-density drilling fluid, keeping mud performance stable and reliable.

- High durability: High-manganese alloy steel box with full heat treatment and heavy anti-corrosion coating, plus wear-resistant screens and premium international electrical components—built to last under high-intensity drilling conditions.

- Flexible adaptability: -1° to +5° bed angle adjustment & dual linear/elliptical vibration modes—tailored to conventional oil/gas, shale gas drilling, and more, matching any on-site fluid property.

- Easy operation: Wedge-type screen fixation for fast replacement, modular structure for simplified installation and maintenance—cutting your operational costs down effectively.

The FLC503 shale shaker is not operated in isolation, but is an important part of TR’s complete solids control system. It works in coordination with equipment such as desanders, desilters, and centrifuges, forming a multi-stage purification chain to achieve deep processing and recycling of drilling fluids.

Currently, this equipment has been widely used in land oil drilling, offshore drilling, shale gas development, trenchless engineering, and other fields. Whether in high-temperature, high-pressure deep well environments, or in complex, easily collapsible formations, TR’s FLC503 drilling fluid shale shaker can provide continuous and reliable solids control support for drilling operations with its stable performance, helping companies reduce drilling costs and improve operational efficiency.

When choosing shale shaker, in addition to paying attention to separation efficiency and durability, the equipment compatibility, ease of maintenance, and the manufacturers technical strength are equally important. As a professional provider of solid control system solutions, TR Solid Control not only offers high-quality FLC503 shale shaker models but can also provide customized designs and comprehensive after-sales services based on customer needs. From equipment selection and installation to commissioning and later maintenance, TR Solid Control ensures full support for drilling operations.

If you are looking for an efficient and reliable shale shaker solution for your drilling projects, the FLC503 model from TR Solid Control is worth considering. It combines advanced design concepts with practical technical features, making it a reliable piece of equipment in drilling solid control systems.

Shale Shaker and Drilling Fluids Systems

In oil and gas drilling, shale shakers and drilling fluid systems form the core unit of solids control systems. As the primary drilling fluid treatment equipment, shale shakers separate cuttings and large solid particles from drilling fluid—ensuring stable drilling fluid properties and creating favorable conditions for downstream solids control equipment. Proper configuration of shale shakers and drilling fluid systems is key to boosting drilling efficiency and controlling operational costs.

During the circulation process, drilling fluid continuously carries formation cuttings back to the surface. If not treated in time, this can adversely affect the performance of the drilling fluid. In the drilling fluid system, the Shale Shaker primarily serves the following functions:

- – Achieve primary solid-liquid separation of the drilling fluid

- – Reduce the solid content in the drilling fluid

- – Alleviate the load on downstream equipment such as sand traps and mud cleaners

- – Improve the reusability of the drilling fluid

Through efficient screening, the Shale Shaker helps maintain stable operation of the drilling fluid system.

In a drilling fluid system, the configuration of the Shale Shaker directly affects the overall solids control performance:

- Screen configuration: Different screens are required for different drilling stages

- Processing capacity: Must meet the circulation flow requirements of the drilling fluid

- Vibration mode: Linear vibrating screens are commonly used for high-volume drilling operations

- Installation and maintenance: Proper installation and regular maintenance help ensure stable system operation

Reasonable configuration helps improve the overall efficiency of the drilling fluid system.

As a professional solid control equipment supplier in China, TR Solid Control has long provided shale shakers and related solid control equipment for drilling fluid systems. TR Solid Control focuses on the following aspects in product design:

- – Equipment structural strength and durability

- – Vibration system operational stability

- – Ease of screen replacement

- – Compatibility with the complete drilling fluid system

Its shale shaker products have been applied in various oil and gas drilling and engineering drilling projects.

With the continuous development of drilling technology, Shale Shakers and drilling fluid systems are also showing new trends:

- – Shaker designs with higher processing capacity

- – More durable screen materials

- – Synergistic operation with automated drilling fluid systems

- – Ongoing improvements in environmental protection and on-site management requirements

These changes are driving the solid control systems toward more stable and efficient development.

Overall, shale shakers and drilling fluid systems play a vital role in drilling solids control processes. With proper selection and standardized operation, shale shakers effectively ensure drilling fluid performance and solids control system stability. Coupled with the mature products and technical support from TR Solids Control, they deliver reliable drilling fluid treatment solutions for drilling projects.

Shale Shaker: The Core of Efficient Solids Control

In oil and gas drilling, the shale shaker is the core of an efficient solids control system, performing the critical function of separating large solid particles from drilling fluid and supplying clean liquid to downstream mud treatment equipment. As the indispensable first line of defense in the solids control workflow, it safeguards drilling fluid quality, boosts operational efficiency, and cuts costs.

A professional solids control equipment manufacturer, TR Solids Control offers a full range of shale shakers—including linear and elliptical models—to meet the demands of diverse drilling projects. With precision engineering and stable performance, TR shale shakers deliver high-efficiency solid-liquid separation, providing dependable support for oil and gas drilling operations.

Shale shakers are the first equipment in a solids control system, primarily used for primary solid-liquid separation of drilling fluid. Their working principle is that a vibration motor generates vibrations, allowing drilling fluid to pass through the screen and separating out large solid particles. Their main functions include:

- Improving solids control efficiency: The Shale Shaker efficiently removes cuttings and solid particles from the drilling fluid, reducing the treatment load of subsequent equipment.

- Extending the lifespan of the mud: By effectively separating solid materials, the Shale Shaker can reduce drilling fluid consumption and improve the recycling efficiency of the mud.

- Optimizing downstream processing: The cleaned liquid phase enters downstream equipment, such as desanders and centrifuges, ensuring smooth subsequent processing.

The Shale Shaker provided by TR Solid Control Equipment performs excellently in drilling solid control systems. Here are several prominent advantages of TR Solid Control Equipment:

- High Stability: The Shale Shaker of TR Solid Control Equipment is designed with a focus on stability, ensuring continuous operation in high-intensity working environments.

- Efficient Separation: Whether it is a linear vibrating screen or an elliptical vibrating screen, the Shale Shaker from TR Solid Control Equipment can efficiently separate large solid particles from drilling fluid, ensuring stable mud performance.

- Long Service Life: The Shale Shaker of TR Solid Control Equipment is equipped with wear-resistant screens, capable of operating stably over a long period under high-intensity drilling operations.

- Strong Adaptability: TR Solid Control Equipment offers various models of Shale Shakers to meet different working conditions according to different drilling fluid characteristics and drilling environments.

The application of Shale Shakers in the oil and gas industry is very extensive, including but not limited to the following areas:

- Conventional oil and gas drilling: Shale Shakers are essential equipment in traditional drilling operations.

- Shale gas drilling: Shale Shakers can efficiently separate solid particles from drilling fluids, maintain fluid properties, and adapt to complex shale gas drilling operations.

- Deepwater drilling: TR solid control equipment’s Shale Shakers can operate stably in high-pressure, high-flow deepwater drilling environments, ensuring efficient circulation of drilling fluids.

The shale shaker is an indispensable core component of drilling solid control systems. It efficiently separates solids from drilling fluid, delivering a stable liquid supply for downstream mud treatment equipment. TR Solids Control provides high-efficiency, stable shale shaker products that are widely used in oil and gas drilling operations globally, offering customers reliable solid control solutions.

Different types of Shale Shakers | How Does it Work

In oil and gas drilling and mud solid control systems, the shale shaker plays a crucial role. It is the first step in the solid separation system, responsible for separating large rock cuttings or solid materials from the drilling fluid to ensure that the mud can be repeatedly recirculated, thereby improving the efficiency and cost-effectiveness of drilling operations.

In the process of oil and gas drilling, the commonly used types of shale shakers mainly include the following:

- Linear Motion Shale Shaker: use a linear movement, generating strong vibrations through dual vibration motors, which can effectively separate large solid particles in the drilling fluid. This type of shaker is suitable for handling drilling fluids with high flow rates and can efficiently discharge solid particles.

- Balanced Elliptical Motion Shale Shaker: use an elliptical movement. This motion ensures a smoother screening process and reduces wear on the equipment. It is suitable for handling finer drilling fluids and can achieve higher separation efficiency.

- Dual-Deck Shale Shaker: have two layers of screens, allowing them to process more drilling fluid simultaneously. They are suitable for drilling operations that require high-capacity handling. They can improve mud handling capacity while maintaining efficient solid separation.

The working principle of shale shaker is essentially to drive screen vibration via a vibratory motor, creating intense motion that propels solid particles in drilling fluid along the screen surface for discharge. During this process, liquid components (e.g., mud) pass through the screen mesh, while larger solids are trapped and removed. The key steps are:

- Drilling fluid flows from the feed box onto the shale shaker; liquid seeps through into the collection tank, and solids remain on the surface.

- The vibratory motor drives linear or elliptical screen motion, pushing solids forward.

- Screened liquid is collected for recycling, and solid particles are discharged as waste.

TR solid control offers various types of shale shakers, each carefully designed to meet the solid separation needs in different drilling environments. TR’s shale shakers have the following advantages:

- High-efficiency solid separation: Whether it’s a linear shale shaker or an elliptical shale shaker, they can efficiently separate solid particles from drilling fluid in a short time, ensuring the recycling rate of the mud.

- Durable screen material: The shale shakers provided by TR use wear-resistant composite material screens, capable of withstanding the high-intensity drilling work environment and extending the equipment’s service life.

- Stable vibration system: TR’s vibration motor and vibration system design ensure stable operation of the equipment, reducing maintenance costs and downtime caused by excessive wear.

- Modular design: TR solid control equipment shale shakers can be integrated with other solid control equipment such as centrifuges and mud cleaner, providing an integrated solution.

The shale shaker plays a crucial role in the solid control system of the oil and gas industry. It not only helps improve the quality of drilling fluid but also reduces mud waste and lowers drilling costs. In addition, the high-efficiency separation capability of the shale shaker can effectively protect subsequent solid control equipment (such as centrifuges and mud cleaner), extending the service life of the equipment.

TR Solid Control provides efficient and stable shale shaker solutions, helping companies improve drilling efficiency, reduce costs, and protect the environment. Choosing the right type of shale shaker and equipment will greatly enhance the operational efficiency of oil and gas drilling.