Tag Archives: drilling mud shale shaker

Shale Shaker – Efficient Mud Control Solutions

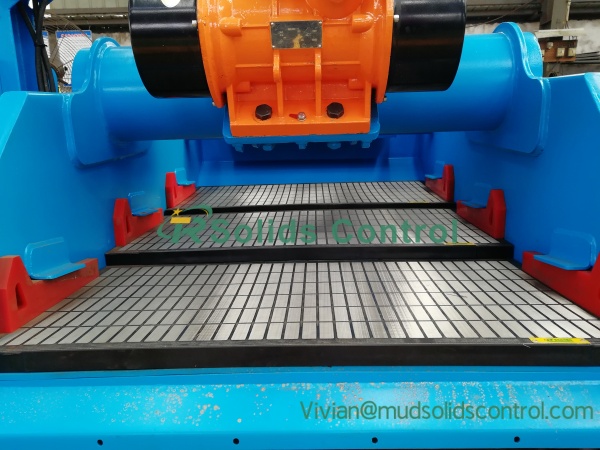

The Shale Shaker is the core link in the oil and gas drilling mud processing system. It is mainly used to screen and separate cuttings and solid particles in the drilling fluid. Through reasonable vibration parameters and screen configuration, the Shale Shaker can improve the recycling rate of drilling fluid and reduce the overall drilling cost while ensuring stable mud performance.

In actual drilling operations, the mud first enters the shale shaker system after returning from the wellhead. The Shale Shaker uses the excitation force generated by the vibration motor to cause the mud to form continuous motion on the screen. The liquid phase enters the mud tank through the screen, while the solid phase particles are transported to the slag discharge port to achieve primary solid-liquid separation.

The Shale Shaker operates based on the vibrating screening principle and mainly includes the following aspects:

- Vibration system: dual vibration motors operate synchronously to form a stable vibration trajectory

- Screen system: Screens with different mesh sizes are suitable for various drilling conditions

- Screen box structure: Reasonable angle design facilitates cuttings transportation and deliquification

- Shock absorbing device: Reduce the impact of equipment operation on the infrastructure

Through these structures working together, the Shale Shaker can continuously and stably complete the primary purification of drilling fluids.

In drilling operations, the use of Shale Shake can bring practical value in many aspects:

- Improve solid control efficiency: separate large solid particles in a timely manner to reduce the burden on subsequent equipment

- Protect drilling fluid performance: reduce mud pollution and facilitate well wall stability

- Reduce operating costs: extend the life of drilling fluids and downstream solids control equipment

- Adaptable to a variety of working conditions: can be used in oil and gas drilling, directional drilling, geothermal drilling and other scenarios

As one of China’s professional solids control equipment suppliers, TR solids control equipment has long been focused on the development and application of Shale Shaker. The drilling shale shakers produced by TR Solid Control Equipment focus on on-site adaptability in terms of structural design, vibration system configuration and screen compatibility, and can be configured and adjusted according to different drilling fluid performance and processing capacity requirements.

In multiple oil and gas drilling projects, the Shale Shaker mud control solution provided by TR Solid Control Equipment has been successfully used in the mud solid-liquid separation process, providing reliable support for the continuity and stability of drilling operations.

Overall, the Shale Shaker mud control solution plays a basic and key role in the drilling solids control system. Through reasonable selection, standardized installation and scientific maintenance, shale shaker equipment can continue to provide stable mud purification effects for drilling operations. Combined with the engineering experience of TR solids control equipment, Shale Shaker mud control solutions are constantly meeting the actual needs of diverse drilling conditions.

Shale Shaker Common Problems: Causes, Symptoms, and Practical Solutions

Efficient solids control starts with identifying and addressing shale shaker common problems early. From screen blinding and excessive vibration to uneven flow and motor faults, many issues can affect drilling fluid treatment. In this guide, we walk through the typical problems operators face and provide clear solutions to restore stable shaker performance.

1. Screen Blinding

- Symptoms: Reduced fluid throughput; Wet solids discharge; Mud pooling on screen deck

- Causes: Fine or sticky solids; Incorrect screen mesh; Low vibration intensity

- Solutions: Switch to a different mesh or composite screen; Increase G-force or deck angle as allowed; Add pre-treatment equipment for heavy solids

2. Premature Screen Damage

- Symptoms: Tears, broken mesh, frame cracks; Frequent screen replacements

- Causes: Over-tensioning; Feeding heavy cuttings directly; Using incompatible screen types

- Solutions: Follow proper screen tensioning steps; Install flow distribution box or buffer plate; Use screens recommended by equipment manufacturer

3. Abnormal Vibration

- Symptoms: Excessive shaking; Loud noise or motor overheating

- Causes: Imbalanced vibrator motors; Worn bearings; Loose mounting bolts

- Solutions: Check motor rotation direction and phase;Inspect bearings and replace if needed;Re-torque all structural fasteners

4. Poor Separation Performance

- Symptoms: Solids bypassing the screen; Mud quality not meeting requirements

- Causes: Wrong screen mesh; Low deck angle; Worn vibration motors

- Solutions: Use suitable mesh and panel type; Adjust deck angle to recommended range; Verify G-force output from motor assembly

5. Uneven Flow Distribution

- Symptoms: One side overloaded; Dry zone and flood zone on same panel

- Causes: Improper positioning of feed pipe; Inconsistent tank level; Unstable pump output

- Solutions: Center the feed inlet; Maintain steady tank level; Use flow control valves or replace faulty pump

6. Motor Overheating

- Symptoms: Hot casing; Thermal trips

- Causes: Wrong voltage; Unbalanced load; Blocked ventilation

- Solutions: Verify power supply; Inspect eccentric weights; Clean motor cooling system

7. Excessive Wear on Shaker Deck

- Symptoms: Deck grooves, corrosion, bolt loosening

- Causes: Using incompatible screen frame materials; High G-force operation over long periods

- Solutions: Install rubber deck seals or cushions; Reduce vibration settings within equipment limits

Conclusion

Understanding common shale shaker common problems helps drilling teams diagnose faults quickly and maintain stable operation. Regular inspection, proper screen selection, and correct installation all play a key role in preventing downtime and improving solids control efficiency.

Main Uses of Shale Shaker in Drilling and Industrial Solids Control Applications

The shale shaker—key to solids control—handles first-stage solid-liquid separation, removing large cuttings/particles from drilling mud/process fluids. Understanding its uses aids in selecting solutions to boost efficiency, reduce waste, and protect downstream equipment.

China-based professional supplier TR Solids Control offers reliable shale shakers for oil/gas drilling, mining, tunneling, and environmental treatment.

1. Shale Shaker in Oil and Gas Drilling

The main use of shale shaker is in oil and gas drilling operations. It performs the primary separation of drilling cuttings from the circulating drilling fluid.

- Removes large solids and prevents them from re-entering the mud circulation.

- Reduces mud viscosity and density.

- Protects centrifuges, desanders, and desilters from overload.

- Improves drilling rate and reduces wear on pumps and pipelines.

A high-performance oilfield shale shaker ensures stable drilling operations, lower mud treatment costs, and longer equipment life.

2. Shale Shaker in Mining and Mineral Processing

- Separation of fine ore particles from slurry.

- Dewatering of mineral concentrate.

- Recycling of water in closed-loop systems.

3. Shale Shaker in HDD (Horizontal Directional Drilling)

- Improves borehole stability and mud reuse efficiency.

- Reduces environmental impact by minimizing waste discharge.

- Extends the lifespan of mud pumps and mixing equipment.

4. Shale Shaker in Tunnel Boring and Piling Projects

- Reduces slurry disposal cost.

- Improves slurry circulation and stability.

- Ensures cleaner operations and compliance with environmental standards.

5. Shale Shaker in Environmental and Waste Management

- Separation of suspended solids from industrial wastewater.

- Dewatering of sludge in oil refinery and chemical plants.

- Treatment of contaminated soil and waste mud.

6. Why Choose TR Solids Control Shale Shakers

- API & ISO certified production.

- Adjustable G-force and deck angle design.

- Durable composite frame screens for long service life.

- Modular design for easy integration with mud systems.

- Strong after-sales service and spare parts supply.

TR shale shakers have been exported to over 40 countries, serving oilfields, construction projects, and environmental protection industries worldwide.

7. Conclusion

The uses of shale shaker go far beyond oil drilling—it plays a key role in various industries requiring efficient solids-liquid separation.From drilling mud treatment to mining and environmental management, shale shakers contribute to cleaner operations, cost savings, and environmental protection.

With its advanced design and reliable quality, TR Solids Control continues to provide customized shale shaker solutions for global customers.

How Shale Shakers Improve the Efficiency of Oil Drilling Mud Treatment Equipment

In every drilling operation, oil drilling mud treatment equipment is essential for maintaining the quality of drilling fluids and ensuring smooth, cost-effective performance. Among these systems, the shale shaker is the first and most critical stage of solids control — removing large drill cuttings from the circulating mud before it proceeds to desanders, desilters, and centrifuges.

By improving mud clarity and reducing wear on downstream equipment, the shale shaker directly determines the efficiency and lifespan of the entire mud treatment process. Understanding its function and features is key to optimizing solids control systems.

1. The Core Role of the Shale Shaker in Mud Treatment Systems

The shale shaker acts as the primary solids separation device within the oil drilling mud treatment equipment. It operates by vibrating a screen or mesh surface, allowing drilling fluid to pass through while capturing larger solid particles.

Key functions include:

- Removing Drill Cuttings: Preventing solids accumulation in the drilling mud.

- Maintaining Mud Properties: Ensuring stable density and viscosity for efficient drilling.

- Protecting Downstream Equipment: Reducing the load on desanders, desilters, and centrifuges.

A properly configured shale shaker ensures cleaner mud recirculation and lowers the overall operating cost of the drilling system.

2. How Shale Shaker Design Affects Performance

Key Design Elements Include:

- Vibration Motors: Dual high-efficiency motors provide stable and adjustable vibration strength.

- Screen Area: Larger screen areas handle greater flow rates.

- Screen Type: Composite frame screens improve durability and filtration accuracy.

- Deck Angle Adjustment: Allows operators to adapt to different mud conditions.

3. Advantages of High-Quality Shale Shakers in Drilling Operations

Investing in a well-designed shale shaker brings significant operational benefits to oil drilling mud treatment equipment systems:

- Improved Separation Efficiency: Removes solids faster and more completely.

- Reduced Mud Loss: Saves expensive drilling fluids through precise control.

- Extended Equipment Lifespan: Less wear on pumps, desanders, and centrifuges.

- Lower Maintenance Costs: Simplified screen replacement and vibration control systems reduce downtime.

- Energy Efficiency: Advanced motors and optimized design minimize power consumption.

These advantages make the shale shaker one of the most cost-effective tools in the entire solids control process.

4. TR Solids Control – A Reliable Supplier of Oilfield Mud Treatment Equipment

TR Solids Control is a professional manufacturer and supplier of oil drilling mud treatment equipment in China. The company specializes in designing and producing shale shakers, mud cleaners, desanders, desilters, vacuum degassers, and decanter centrifuges for oil & gas drilling, HDD, and environmental projects.With years of experience and strict quality control, TR has become a trusted partner for customers worldwide seeking efficient and durable solids control solutions.

5. Choosing the Right Shale Shaker for Your Mud Treatment System

Selecting a suitable shale shaker depends on several factors, such as:

- Drilling Depth and Mud Volume

- Flow Rate and Solids Concentration

- Power Supply and Motor Type

- Screen Mesh Size and Material

- Environmental and Space Requirements

By consulting with experienced manufacturers like TR Solids Control, operators can configure a customized oil drilling mud treatment equipment package that meets their specific drilling needs.

Conclusion

The shale shaker is the foundation of every efficient oil drilling mud treatment equipment system. Its performance determines the effectiveness of solids control and the quality of recycled drilling fluids. Choosing a reliable, high-performance shale shaker not only boosts drilling efficiency but also reduces operational costs and environmental impact.

For dependable shale shakers and complete mud treatment systems, TR Solids Control continues to deliver professional solutions trusted by oilfield operators worldwide.

Shale Shaker for Sale

Mud shale shaker has become an indispensable assistant with its unique screening function In the drilling mud solid control system. We are going to introduce you to a mud shale shaker for sale (TR mud shale shaker).It will bring efficient and accurate screening experience to your production process and saving costs.

First, excellent performance

Shale shaker for sale is marketed using design concepts and manufacturing processes to ensure superior performance in screening operations. It is equipped with a high-strength vibration motor. It can produce a strong and stable exciting force. so that the material is quickly dispersed on the screen surface and screened efficiently. Whether it is a fine powder or a larger particle, meet your screening requirements for different materials.

Its unique shaker screen design has high wear resistance and good screening effect. We carefully select high-quality materials to make the screen. it ensure that it is not easy to damage during a long time of use,reducing your maintenance costs.

shale shaker for sale also has a high screening efficiency and processing capacity. It can quickly separate impurities and unqualified products in the material to improve the quality and purity of the product. Compared with traditional screening equipment, its processing capacity can be increased by more than 30%.

advantage for shale shaker for sale

In an industrial production environment, the durability and reliability of equipment are of Paramount importance. We know this, so in the manufacturing process of this shale shaker for sale, we strictly control every link to ensure the quality of the product.

Its main structure is made of high-quality steel, which has been carefully welded and processed, and has the characteristics of strong durability and stability. Even under harsh working conditions, it can run stably for a long time to provide reliable support for your production.

In addition, we have equipped this shale shaker for sale with high-quality bearings and seals to ensure smooth operation and sealing of the equipment. These critical components are subject to rigorous quality testing and have a long service life, reducing your downtime and repair costs due to equipment failure.

Easy to operate for shale shaker for sale

We have been committed to providing users with a more convenient and efficient equipment operation experience. This Shale Shaker for Sale is designed with human factors in mind, easy to operate and easy to maintain.

In terms of equipment maintenance, we also provide you with great convenience. The components of this shaker are modular in design for easy disassembly and replacement. When the equipment needs maintenance or maintenance, you can simply operate, you can quickly complete the relevant work, saving your time and effort.

Fourth, quality service, worry free after sale

We not only provide you with high quality shaker products. We have a professional after-sales service team. we can provide you with timely and efficient technical support and after-sales service.

No matter you encounter any problems in the installation, commissioning and use of the equipment.our after-sales service personnel will provide you with solutions in the first time.

Choosing our shale shaker for sale means choosing an efficient, accurate, reliable and energy efficient screening solution. It will bring higher production efficiency, better product quality and greater economic benefits to your business. If you are looking for a mud shaker with excellent performance and an affordable price, then do not hesitate to contact us today so that we can provide you with professional service and quality products.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:18509252400

E-mail:sales@trsolidscontrol.com

Mud Shale Shaker

Mud shale shaker is a kind of equipment commonly used for solid-liquid separation, mainly used to screen and filter solid particles in mud, commonly used in oil drilling, coal mines, construction sites and other industries. The slurry shaker screen separates the solid particles in the slurry through the shaker screen, so as to realize the treatment of waste sludge and the separation of liquid and solid.

TR Solids Control is a manufacturer of mud shale shakers

The shale shaker consists of a screen and an oscillator. The working principle of the mud shaker is to generate force through the rotating motion of the vibrating motor, which causes the mud to vibrate on the screen.

The use of slurry shale shaker helps to improve the efficiency of slurry treatment, reduce waste disposal costs, protect the environment. When using a slurry shaker, you need to pay attention to regular cleaning and maintenance of the equipment to ensure that it is working properly.

TR Solids Control is a professional manufacturer of mud shale shakers and solid control equipment. TR can provide replacement mud shale shaker of derrick, swaco mongoose shakers. If you need any one model drilling shale shaker, TR solid control will provide you with a high quality mud solids control equipment. We can also customize the shale shaker for your requirements.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

E-mail:sales@trsolidscontrol.com

Drilling Shale Shaker

Drilling Shale Shaker is the third generation of linear motion shaker. Mud Shale Shaker is using the horizontal excitation of vibration motor as vibration source, material on the sieve was up forward for linear motion,referred to as Linear Shaker, also known as linear shaker; Drilling Shale Shaker is the most widely used mud shale Shaker. All Mud Shale Shaker is TR Solids Control designed by ourselves, including Balanced Elliptical motion Shaker and Mongoose shale shaker.All shaker screens can be fit on drilling shale shaker by wedge blocks or hooks.

DERRICK is the world’s leading manufacturer of drilling shale shaker. Derrick FLC503 shakers are popular in Middle Eastern countries. TR Production replaces derrick FLC503 drilling shale shakers.

TR is a well-known Chinese shaker manufacturer. Drilling shale shakers are well proven at the drilling site and have been tested by third parties.TR produces drilling shakers and also produces shaker screens. For example, DERRICK FLC503 Screen,Hyperpool Screen,Mongoose Screen. The shaker screen produced by TR has been API 13C tested and sold to many regions around the world. We’d be happy to contact you if you need to replace Derrick screen.

Advantage of Drilling Shale Shaker

- Vibration strength can be adjusted

- Vibration track uniform

- Screen options more choice

- Vibrating Strength 7.5G

We are an exporter of Drilling Mud Shale Shaker. Our factory approval the API, shale shakers have the API certification. TR solids control is the designed, selling, production, service and delivery of Chinese drilling fluids shale shaker manufacturers. We will provide the high quality shale shakers and best service. Your best shale shaker start from TR solids control.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

Elliptical Motion Shale Shaker

Elliptical Motion shale shaker, high-performance shakers of today are able to use 120 mesh and shaker screens at the flow line in most applications.

Oilfield shale shaker development may be defined by the types of motion produced by the machines:

Unbalanced BEM shale shaker; Balanced Circular motion shale shaker; Linear shale shaker; Balanced motion shale shaker.

At present commonly used shale shaker is the linear motion shale shaker. The balanced elliptical motion shale shaker is more difficult to design than linear motion shale shaker, but TR Solids Control designs some new balanced elliptical shale shaker.

elliptical motion shale shaker handling capacity can increase by 30%, the speed of conveying sand and excluding scrap increase by 20%. And it can efficiently get rid of screen blocking, and screen pasting.

Technical characteristics High screening efficiency:

Because of the elliptical vibration track, the movement of the material on the screen surface is more complicated, which is conducive to improving the screening efficiency. Large processing capacity: the translational elliptical vibrating screen has a large screening area and high vibration strength, and can handle a large number of materials. Screen is not easy to block: Because the material is subjected to high-frequency vibration on the screen surface, it can effectively prevent screen blocking. Energy saving and environmental protection: stable operation of the equipment, low power consumption, in line with the requirements of energy saving and environmental protection.

We are an exporter of Shale Shaker.Our factory approval the API,Drilling Shale Shaker have the API certification.TR solids control is the designed,selling,production,service and delivery of Chinese drilling fluid Shale Shaker manufacturers.We will provide the high quality drilling Shale Shaker and best service.Your best mud Balanced Elliptical motion shale shaker start from TR.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:13186019379

Call:13186019379

E-mail:sales@trsolidscontrol.com

E-mail:sales@trsolidscontrol.com

Web:www.trsolidscontrol.com

Mud linear shale shaker introduction

Mud linear shale shaker paly big part role in the first stage of solid control system to get off the big particle of drilling mud ,we could offer the different capacity shale shaker based on the demand of our customer .we also could offer the Triple shale shaker and double shale shaker we already developed the third generation linear shale shaker and the fourth generation balanced shale shaker.

Mud linear shale shaker were solely designed and manufactured by our company but with the advantages of same international well-known products,containing more than one patents

The drilling mud shale shakers being provided with high vibration intensity , adjustable-pitch ,compact, reliable ,behavior and cost effective ,is known as a competitive product in the international market.

Mud linear shale shaker is the third generation of shale shaker .it was widely used for the oil industry and perfect fit the enviromental.

The advantage of TR Mud linear shale shaker:

1:Shaker track is linear.

2:Simple struction and short producing time.

3: Flexible shale screen, lower cost.

4:Rust protection take in shot blasting.

5:Surface rust protection.

6: Internation brand of Motor.

We are an exporter of Shale Shaker.Our factory approval the API, Shale Shaker screens have the API certification.TR solids control is the designed,selling,production,service and delivery of Chinese drilling fluid Linear Shale Shaker manufacturers.We will provide the high quality drilling Shale Shaker and best service.Your best mud shale shaker start from TR solids control.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com