Tag Archives: TR Shale Shaker Parts

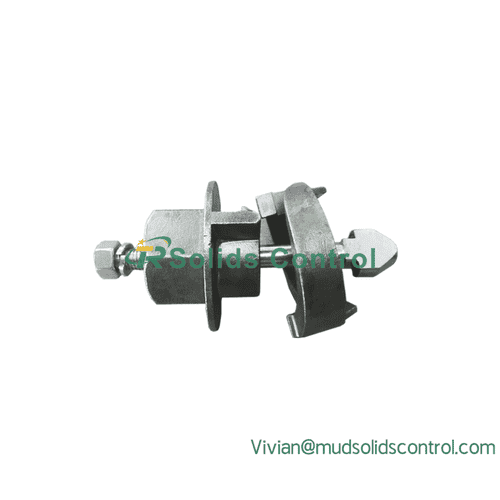

Shale Shaker Tensioning Assembly – Ensuring Secure Screen Installation for Efficient Solids Control

The shale shaker tensioning assembly is an essential component in drilling solids control equipment. Designed to firmly secure shaker screens to the shaker deck, the tensioning assembly ensures efficient separation of drill cuttings from drilling fluids. Without a reliable tensioning system, screens may loosen, causing fluid bypass, reduced solids removal efficiency, and unnecessary mud loss. By maintaining proper screen stability, the shale shaker tensioning assembly plays a key role in the overall performance of shale shakers.

Functions of a Shale Shaker Tensioning Assembly

Screen Stability – Keeps shaker screens firmly in position during vibration.

Efficient Solids Removal – Ensures all drilling fluids pass through the mesh for maximum filtration.

Leakage Prevention – Reduces the risk of drilling mud bypassing around the screens.

Extended Screen Life – Minimizes damage from uneven wear caused by loose fitting.

Benefits of High-Quality Tensioning Assemblies

Reliable Performance – Maintains consistent screen tension even under high G-force conditions.

Durability – Resistant to abrasion, vibration, and exposure to drilling fluids.

Easy Maintenance – Allows quick installation and replacement of screens.

Cost Efficiency – Reduces downtime and improves overall drilling productivity.

Conclusion

A shale shaker tensioning assembly may seem like a small component, but it is critical for reliable solids control operations. By keeping shaker screens secure, preventing mud loss, and improving separation efficiency, this assembly ensures better drilling performance and reduced operational costs. For long-lasting and stable performance, choosing a high-quality tensioning assembly is essential for any shale shaker system.

Shaker Screen Tensioning Device – Key Component for Reliable Shale Shaker Performance

A shaker screen tensioning device is one of the most important parts of a shale shaker, ensuring that screens are held firmly in place for efficient solids separation. Without proper screen tensioning, drilling fluids can bypass the screen mesh, leading to poor solids control, higher mud loss, and reduced shaker efficiency. By keeping screens tightly secured to the shaker deck, the shaker screen tensioning device plays a vital role in reliable drilling operations.

Functions of a Shaker Screen Tensioning Device

Firm Screen Positioning – Prevents screen movement or looseness during vibration.

Improved Separation Efficiency – Ensures drilling fluids pass through the screen for maximum solids removal.

Leakage Prevention – Reduces mud bypass and improves fluid recovery.

Extended Screen Life – Prevents excessive wear and damage caused by improper fitting.

Benefits of High-Quality Tensioning Devices

Consistent Performance – Maintains stable screen tension even in high-G force shale shakers.

Durable Construction – Resistant to vibration, abrasion, and drilling fluids.

Easy Installation & Replacement – Saves time during screen changes.

Lower Operational Costs – Reduces downtime and prevents unnecessary screen replacements.

Conclusion

The shaker screen tensioning device may seem like a small accessory, but its role in shale shaker performance is critical. By keeping screens secure, preventing leaks, and ensuring efficient solids control, it directly improves drilling fluid management and reduces operational costs. For reliable and long-lasting performance, investing in high-quality shaker screen tensioning devices is essential for any drilling project.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/

Shale Shaker Rubber Strip – Essential Sealing Part for Solids Control Equipment

The shale shaker rubber strip is a critical sealing component used in drilling solids control systems. Installed between the shaker deck and shaker screens, rubber strips ensure proper sealing, prevent drilling fluids from bypassing the screens, and protect equipment from excessive wear. By maintaining efficient screen performance, shale shaker rubber strips directly contribute to reliable solids control, reduced mud loss, and extended service life of shaker parts.

Functions of a Shale Shaker Rubber Strip

Sealing Protection – Prevents drilling mud leakage between the screen and frame.

Improved Screen Efficiency – Ensures all drilling fluids pass through the screens for proper solids removal.

Vibration Absorption – Reduces screen damage caused by continuous vibration.

Longer Equipment Life – Minimizes wear on shaker screens and deck components.

Benefits of High-Quality Rubber Strips

Durability in Harsh Conditions – Resistant to oil, heat, and chemical exposure.

Easy Replacement – Designed for quick installation and maintenance.

Cost Savings – Reduces drilling fluid loss and extends shaker screen lifespan.

Stable Performance – Maintains consistent sealing throughout drilling operations.

The shale shaker rubber strip is widely used in:

Oil & Gas drilling – Ensures reliable solids control in deep wells.

HDD (Horizontal Directional Drilling) – Improves mud recovery in trenchless projects.

Mining & Tunneling – Enhances slurry separation efficiency in heavy-duty environments.

Conclusion

A shale shaker rubber strip may seem like a small accessory, but it plays a big role in solids control performance. By ensuring a secure seal, reducing mud loss, and protecting shaker screens, it supports efficient drilling operations and cost savings. Choosing durable, high-quality rubber strips is essential for maximizing shale shaker efficiency and extending equipment life.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/

Essential Shale Shaker Parts for Reliable Solids Control Operations

Reliable shale shaker parts are the backbone of efficient solids control operations in drilling projects. As the first stage of solids removal, shale shakers depend on high-quality components to separate drill cuttings from drilling fluids, reduce wear on downstream equipment, and optimize mud recovery. Understanding the role of each shale shaker part helps operators achieve consistent drilling performance and minimize costly downtime.

Key Shale Shaker Parts

Shaker Screens

Shaker screens are the most vital parts of a shale shaker. Built with durable stainless steel mesh, they filter solids while allowing clean drilling fluid to pass through. Selecting the right mesh size ensures precise solids control and maximum fluid recovery.

Shaker Screen Tensioning Device

This device secures shaker screens tightly to the deck, preventing leaks and ensuring stable performance. A reliable tensioning system allows quick screen changes and reduces downtime during drilling operations.

Shale Shaker Spring

Springs absorb vibration and isolate motion, protecting the shaker structure from excessive stress. High-quality shale shaker springs improve operational stability, reduce noise, and extend equipment life.

Shaker Screen Support

The screen support provides a solid foundation for screens under heavy loads. Strong supports maintain even distribution of vibration, preventing premature screen wear and ensuring efficient solids separation.

Screen Wedge

Screen wedges lock screens in place for secure operation. They simplify installation and replacement, helping crews maintain efficiency while keeping the shaker running safely and reliably.

Why High-Quality Parts Matter

Investing in durable shale shaker parts minimizes failures, reduces maintenance costs, and ensures compliance with drilling standards. Quality components not only improve solids control but also protect expensive downstream equipment such as desanders, desilters, and centrifuges.

Conclusion

From shaker screens and tensioning devices to springs, supports, and screen wedges, each shale shaker part plays a critical role in solids control operations. Using reliable components ensures efficient fluid management, longer equipment lifespan, and lower overall drilling costs—making these parts indispensable for any oilfield or HDD project.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/h