Tag Archives: solid control equipment manufacturer

Shale Shaker Benefits in Drilling Applications

In oil and gas drilling, shale shakers are indispensable solid control devices that directly impact drilling mud purification and overall construction progress. As the first solid control barrier, they use optimized vibration frequencies and screen designs to efficiently separate cuttings, sand, and other solid particles from drilling mud—ensuring stable circulating mud performance and laying the foundation for smooth drilling. Suitable for onshore and offshore operations alike, shale shakers reduce equipment wear from solids, minimize mud waste, boost drilling fluid recycling rates, and meet the oil and gas industry’s dual demands for efficiency and cost control.

1.Optimise drilling mud performance to ensure drilling safety

A core function of shale shakers is rapid drilling mud purification: after mud carries cuttings to the surface, shale shakers promptly separate solid impurities, preventing abnormal viscosity/density that risks wellbore collapse or stuck drill pipe. High-quality models adjust vibration parameters to mud characteristics and cuttings size, ensuring efficient solid-liquid separation, preserving mud’s lubrication, cooling, and sand-carrying capabilities, and indirectly extending drilling equipment lifespan by maintaining optimal working conditions for drill bits and strings.

2. Reduce construction costs and improve resource utilisation

In oil and gas drilling, drilling mud materials and equipment maintenance represent significant costs. Shale shakers efficiently separate solid particles, enabling purified mud to be reused in the circulation system—greatly reducing the need for new mud and lowering material consumption costs. Additionally, they minimize wear on key equipment, reducing failure and maintenance frequency, and effectively controlling drilling costs through both material and maintenance savings.

3. Adapt to complex drilling scenarios and enhance operational stability

Oil and gas fields feature diverse geological conditions, with varying cuttings characteristics and mud types. High-quality shale shakers offer strong adaptability: interchangeable screens of different apertures, plus adjustable vibration amplitude and frequency, enable them to meet solid-liquid separation needs across geological conditions. Whether drilling in complex formations or operating in high-temperature, high-pressure environments, they deliver consistent separation performance, ensuring drilling continuity and minimizing interruptions from inadequate solid control.

4.Supporting environmental compliance and reducing environmental impact

During oil and gas drilling, improperly disposed waste mud can pollute surrounding soil and water. Shale shakers efficiently separate solid particles, allowing purified mud to be recycled, thereby reducing waste mud discharge; meanwhile, the separated cuttings can be dried and further recycled or properly disposed of, minimizing the negative environmental impact of drilling operations, supporting drilling projects to meet environmental regulations, and achieving green drilling.

Amid the oil and gas drilling industry’s focus on efficiency, safety, and environmental protection, shale shakers are growing in application value. Selecting highly adaptable, efficient shale shakers enhances solids control to keep drilling operations on track, while also driving more value for projects through cost control and environmental compliance. As drilling technology advances, shale shakers will continue to evolve toward intelligence, efficiency, and eco-friendliness, supporting the industry’s high-quality development.

Drilling Shale Shaker: Applications and Value in Oil-Gas Solids Control

In the process of oil and gas exploration and development, the Drilling Shale Shaker is one of the core pieces of equipment in the drilling solids control system, mainly used for the primary solid-liquid separation of drilling fluid. Through high-frequency vibration and screen filtration, the shaker can effectively separate cuttings and maintain the stability of the drilling fluid.

The Drilling Shale Shaker provided by TR Solids Control is widely used in various types of drilling projects due to its reasonable structural design, stable operation, and adaptability to different working conditions.

Basic working principle of a Shale Shaker: Regular vibrations are generated by a vibrating motor, causing the drilling fluid to form a flow path on the screen surface: drilling fluid passes smoothly through the screen for recovery; solid particles are retained and quickly discharged; reduces the sand content in the drilling fluid; improves the operating conditions of subsequent solids control equipment.

TR Solids Control in the design and application of Drilling Shale Shakers, focuses on equipment stability and practicality, mainly reflected in:

– Multiple mesh configurations to adapt to different drilling fluid systems

– Dual motors or linear vibration structures to ensure screening efficiency

– Adjustable screen box angles to meet different flow and viscosity requirements

– Modular structural design for easy on-site maintenance and replacement

Application Scenarios of Drilling Shale Shaker in Drilling Solid Control Systems

Onshore oil and gas drilling projects

Offshore platform drilling projects

Directional and horizontal well operations

High-circulation drilling fluid handling systems

By properly configuring the Drilling Shale Shaker, the overall efficiency of the solid control system can be effectively improved.

How to Choose the Right Drilling Shale Shaker?

When selecting a model, you can focus on the following factors:

– Drilling fluid handling capacity and flow requirements

– Screen size and ease of replacement

– Vibration type and excitation force parameters

– Stability of continuous equipment operation

– Manufacturer’s technical support and service capabilities

TR solid control equipment can provide various models of Drilling Shale Shakers according to different drilling conditions, meeting the diverse needs of projects.

As an important component of the drilling solid control system, the Drilling Shale Shaker plays a crucial role in ensuring the quality of drilling fluid, reducing equipment load, and improving operational efficiency. With the application experience of TR solid control equipment, it can provide more stable and sustainable solid control solutions for oil and gas drilling projects.

Understanding Shale Shaker Screen Material and Its Impact on Drilling Efficiency

In oil and gas drilling, the shale shaker (first-stage solids control core) relies heavily on screen material—right selection boosts filtration accuracy, durability, and drilling efficiency. China-based TR Solids Control provides high-quality shaker screens with advanced materials for optimal separation and long service life in oilfield projects.

1. What Is Shale Shaker Screen Material?

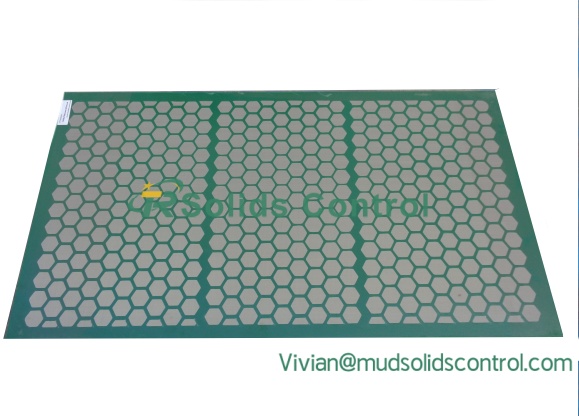

Shale shaker screen material (metal mesh + supporting structure) filters drilling cuttings from circulating mud. Designed to withstand vibration, corrosion, and high flow in harsh conditions, it dictates filtration precision, wear/corrosion resistance, strength, flow capacity, and service life. High-quality screens maintain mud properties, reduce fluid loss, and enhance drilling performance.

2. Common Types of Shale Shaker Screen Materials

Different drilling environments require specific screen materials to achieve optimal separation. The main materials used in drilling shale shaker screens include:

- Stainless Steel Wire Mesh:Widely used (SS304/316/316L), offering corrosion/tensile/wear resistance. Suitable for water/oil-based mud. TR Solids Control weaves fine stainless steel into multi-layer screens for precise separation and long service life.

- Composite Material Frame:Combines high-strength polymer + stainless steel mesh. Lightweight, rust-free, impact-resistant, easy to handle. Ideal for offshore/high-humidity environments; absorbs vibration and reduces screen damage.

- Carbon Steel/Galvanized Frame:Cost-effective with high rigidity for standard applications. Requires galvanizing/epoxy coating to prevent corrosion. Suitable for land drilling with moderate conditions.

- Polyurethane Screens (Optional):For coarse screening or abrasive formations. Offers excellent abrasion resistance and flexibility; ideal for high-solids mud.

3. Screen Layer Configuration

Shale shaker screens use 2–3 layers for balanced strength and separation: top (fine mesh, precision), middle (structural stability), bottom (backing mesh, protection/even vibration). TR Solids Control uses high-temperature bonding for strong interlayer adhesion and consistent screen performance.

4. How Material Quality Affects Drilling Performance

- Higher solids removal efficiency and cleaner drilling mud.

- Reduced fluid loss and lower mud cost.

- Extended screen life and fewer replacements.

- Improved drilling rate and equipment reliability.

Inferior materials may cause frequent screen damage, poor filtration, or fluid leakage, leading to increased downtime and maintenance costs.

5. TR Solids Control Shale Shaker Screen Features

- As a professional manufacturer, TR Solids Control provides shale shaker screens compatible with major brands such as Derrick®, Swaco®, and Brandt®.

- Stainless steel mesh (SS304 / SS316L) for corrosion resistance.

- Composite frame design for lightweight durability.

- CNC laser cutting for high precision and consistent quality.

- API RP13C compliance for mesh size and performance standards.

- Each screen is tested for tension strength, permeability, and wear resistance before delivery.

6. Conclusion

The shale shaker screen material plays a decisive role in solids control efficiency, maintenance cost, and overall drilling performance.By selecting high-quality stainless steel mesh and composite frame screens from TR Solids Control, drilling operators can achieve stable operation, cleaner drilling mud, and longer service life.Whether for land rigs or offshore platforms, TR provides reliable screen materials and customized solutions to meet your project needs.

Comprehensive Shale Shaker Installation Guide for Oilfield Solids Control Systems

The shale shaker is essential for oilfield solids control—correct installation ensures stable operation, less downtime, and longer life. This guide covers proper installation steps, safety notes, and adjustments for efficient drilling fluid processing.

China-based TR Solids Control offers complete shale shaker solutions and on-site technical support for optimal performance.

1. Preparation Before Installation

Before installing the shale shaker, ensure all tools, accessories, and lifting equipment are ready. Carefully inspect the shaker body, screens, and vibration motors for any damage during transportation.TR Solids Control recommends using a reinforced steel base or skid-mounted frame for stable installation on drilling rigs or mud tanks.

2. Positioning the Shale Shaker

Place the shale shaker in the designed position above the mud tank or solids control system skid.Make sure that:

- The discharge outlet aligns with the mud tank inlet.

- The fluid flow direction matches the tank layout.

- The shaker sits horizontally with a slight incline (typically 3°–5°) toward the discharge end to ensure proper flow of drilling mud.

If multiple shakers are installed in parallel, maintain equal spacing for maintenance access and balanced mud flow.

3. Connecting the Pipeline and Electrical System

Once the shaker is in place, connect the inlet and outlet pipelines:

- The feed line should connect the flow line or mud return system to the shaker’s inlet.

- The discharge line should direct processed mud to the next tank or centrifuge feed section.

Electrical installation should be handled by certified technicians:

- Ensure the vibration motor is connected correctly to the power supply.

- Check rotation direction — the two motors must rotate in opposite directions to create linear vibration.

- Verify all cables are securely fixed and protected from mechanical damage.

4. Installing and Tensioning Shaker Screens

Proper screen installation is crucial for optimal separation efficiency.Steps for installing shaker screens:

- Open the shaker cover or screen frame lock.

- Clean the screen bed surface to remove dust or mud.

- Place the screen panels in the correct order (coarse mesh first if multi-layered).

- Tighten the tensioning bolts or wedges evenly to ensure no gaps or loose points.

- Close and secure the screen cover.

TR Solids Control shale shakers use quick-lock screen systems, allowing operators to replace screens easily without tools, reducing downtime during drilling operations.

5. Final Checks Before Start-Up

- Inspect all fasteners, ensuring they are tightened properly.

- Confirm electrical grounding and motor insulation are secure.

- Make sure the vibration isolation pads are evenly placed under the shaker base.

- Test-run the shaker for 10–15 minutes to check for abnormal noise or excessive vibration.

If everything runs smoothly, connect the shaker to the drilling mud circulation system and begin normal operation.

Conclusion

A properly installed shale shaker is critical to the performance of the entire drilling mud system. Following this shale shaker installation guide helps operators achieve efficient solids control, reduced maintenance, and extended equipment service life.

For professional guidance, customized solutions, and reliable shale shaker equipment, contact TR Solids Control — your partner in advanced solids control and waste management systems.

Drilling Mud Screening System for Effective Solids Control in Oilfield Operations

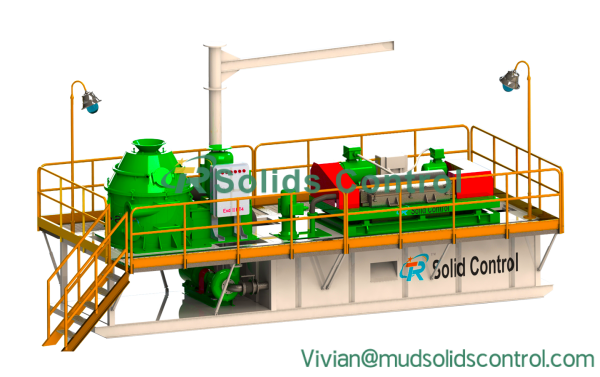

In oil and gas drilling, clean, stable drilling mud ensures safe, efficient, eco-friendly operations. The mud screening system—solids control’s first key stage—separates cuttings/large particles from fluid before downstream equipment.China-based supplier TR Solids Control designs/manufactures complete mud screening systems, offering reliable performance, long life, and easy maintenance for on-site fluid recycling.

1. What Is a Drilling Mud Screening System?

A drilling mud screening system removes cuttings and solid impurities from mud via mechanical separation. Its core component, the shale shaker, filters solids using high-frequency vibration and fine mesh screens.Cleaned mud then flows to tanks or units like desanders/desilters/centrifuges for further purification, ensuring proper fluid properties, less waste, and protected equipment.

2. Main Components of a Mud Screening System

A standard mud screening system from TR Solids Control usually includes:

- Shale Shaker: The first-stage equipment for coarse solids removal.

- Screen Panels: Multi-layer composite mesh screens for effective filtration.

- Feeding Box & Flow Distributor: Directs drilling fluid evenly onto the screen surface.

- Vibration Motors: Provide adjustable G-force for efficient solids separation.

- Mud Tank: Stores screened drilling fluid for reuse.

- Control Panel: Allows operators to adjust vibration frequency and monitor performance.

These components work together to ensure steady mud circulation and continuous solid-liquid separation during drilling.

3. TR Solids Control Mud Screening Systems

TR Solids Control offers several mud screening system models suitable for different drilling projects:

- TRZS703 Linear Motion Shale Shaker System:Capacity: 240 m³/h,|Screens: 3 panels|Adjustable deck angle and vibration force|Ideal for oilfield and HDD projects

- TRZS584 Shale Shaker System:Compact 4-panel design|Flow rate: 130 m³/h|Suitable for small to medium drilling rigs

Each system is customizable based on flow requirements, mud properties, and rig layout. TR also integrates the shakers into complete solids control systems, including desanders, desilters, and centrifuges.

4. Benefits of Using a Mud Screening System

An efficient drilling mud screening system provides multiple operational advantages:

- Maintains optimal drilling mud density and viscosity.

- Reduces wear on pumps and downstream equipment.

- Lowers drilling fluid consumption and disposal cost.

- Improves rate of penetration and drilling stability.

- Promotes environmental compliance by minimizing waste.

With TR Solids Control’s advanced design, operators achieve high separation efficiency and consistent system performance across different drilling conditions.

5. Conclusion

A well-designed drilling mud screening system is essential for any modern drilling operation. It ensures the stability of drilling fluids, enhances safety, and reduces environmental impact.

With reliable equipment, advanced technology, and strong customer service, TR Solids Control remains a trusted partner for global drilling contractors seeking high-performance solids control solutions.

Solids Control Equipment Models Explained – Guide to Efficient Drilling Mud Treatment Systems

In oil and gas drilling, solids control equipment maintains fluid quality and boosts efficiency; understanding its models helps contractors choose the right system for cost-effective performance. China-based professional manufacturer TR Solids Control provides complete solids control systems and various models for reliable drilling mud treatment.

1. Overview of Solids Control System

A complete solids control system is composed of several main units that work together to remove solids from the drilling fluid. The major components include:

- Shale Shaker: The first-stage equipment for coarse solids removal.

- Desander and Desilter: Used for secondary and tertiary separation of fine solids.

- Decanter Centrifuge: Handles ultra-fine particles and ensures clean fluid recycling.

- Vacuum Degasser: Removes gas bubbles from the mud.

- Mud Agitator & Mud Tank: Keep the drilling fluid evenly mixed and stored.

Each of these units has different models designed for specific drilling capacities and mud conditions.

2. TR Solids Control Equipment Models

TR Solids Control provides a wide range of solids control equipment models, covering every stage of mud processing.

- Shale Shaker Models:TRZS703 Linear Motion Shale Shaker:3-panel design, 240 m³/h capacity, suitable for oilfield and HDD projects.TRZS584 Linear Motion Shale Shaker:4-panel design, compact size, efficient solids separation for smaller rigs.

- Desander Models:TRCS250-2S Desander:Equipped with two 10″ hydrocyclones, ideal for medium-capacity mud systems.TRCS300-3S Desander:Larger flow rate, used in high-volume drilling operations.

- Desilter Models:TRCN100-8N Desilter:8 cones (4″), excellent for removing fine solids below 20 microns.TRCN150-12N Desilter:12 cones (4″), higher efficiency for continuous drilling fluid treatment.

- Decanter Centrifuge Models:TRLW355×1250 Centrifuge:Standard oilfield model with adjustable speed and high separation precision.TRLW450×1000 Centrifuge:Compact structure and stable operation for environmental and HDD use.

- Vacuum Degasser Model:TRZCQ270 Vacuum Degasser:Removes entrained gas to protect pumps and improve fluid stability.

3. Choosing the Right Solids Control Equipment Model

Selecting suitable solids control equipment models depends on multiple factors such as:

- Mud properties (viscosity, density, and solids content).

- Drilling depth and rig size.

- Desired flow rate and separation accuracy.

- Available space and installation layout.

TR Solids Control engineers provide professional recommendations and customized system designs to ensure optimal mud processing performance.

4. Advantages of TR Solids Control Equipment

- Durable materials and corrosion-resistant coating.

- Modular design for easy assembly and transport.

- Energy-efficient motors and low noise operation.

- Quick maintenance and convenient spare parts supply.

- Widely used in oilfield drilling, HDD, CBM, and geothermal projects.

Our products have been exported to more than 40 countries, earning recognition for stable quality and competitive pricing.

5. Conclusion

Understanding solids control equipment models is essential for building an efficient and reliable drilling fluid treatment system. Whether you need a high-capacity shale shaker, precision centrifuge, or a complete solids control solution, TR Solids Control provides the right model to meet your operational requirements.

Environmental Benefits of Shale Shakers in Oilfield Drilling Operations

In modern drilling projects, environmental protection has become a key consideration for every oilfield operation. The environmental effect of shale shakers plays a crucial role in achieving cleaner, safer, and more sustainable drilling processes. As the first stage of the solids control system, shale shakers help remove large solids from drilling fluids, reduce waste generation, and support the reuse of valuable resources.

With the growing focus on green energy and responsible drilling, efficient shale shakers are now essential for balancing productivity with environmental responsibility.

1. The Role of Shale Shakers in Eco-Friendly Mud Management

During drilling, the drilling mud carries rock cuttings to the surface. Without proper separation, these solids can contaminate the environment and increase disposal volumes. The shale shaker effectively screens out unwanted particles, allowing the cleaned mud to be reused in the circulation system.Minimizes chemical use by maintaining mud quality and reducing dilution needs.Through efficient oilfield solids control, shale shakers help reduce the environmental footprint of drilling projects.

2. How Efficient Shale Shakers Contribute to Environmental Protection

The environmental effect of shale shakers is closely tied to their efficiency and design. Modern shale shakers are engineered to maximize separation precision while minimizing energy consumption and fluid loss.

Key design features include:

- High G-force linear motion for improved separation.

- Composite frame screens for longer service life and reduced waste.

- Adjustable deck angle for better fluid recovery.

- Low-noise vibration motors for a safer and cleaner working environment.

These innovations allow shale shakers to operate continuously and efficiently, supporting environmentally responsible drilling operations.

3. Reducing Drilling Waste Through Effective Solids Control

The proper use of shale shakers in solids control systems can significantly reduce the volume of drilling waste. By separating cuttings at the earliest stage, less contaminated fluid reaches downstream equipment such as desanders, desilters, and centrifuges.

This reduces the total amount of waste generated and the cost of transportation and disposal. Additionally, cleaner fluids reduce the need for new mud preparation, saving both water and chemical resources — key aspects of sustainable drilling practices.

4. The Broader Environmental Impact of Shale Shaker Technology

The environmental benefits of shale shakers go beyond just fluid separation. They form part of a broader waste management strategy that helps operators comply with environmental regulations and improve corporate sustainability.

By implementing efficient shale shaker systems, oilfield companies can:

- Lower the risk of surface contamination.

- Recycle drilling mud for multiple uses.

- Cut down on energy and material consumption.

- Reduce carbon emissions associated with waste handling and disposal.

In this way, shale shakers are not only technical tools but also essential contributors to eco-friendly oilfield operations.

The environmental effect of shale shakers is an increasingly important topic in oilfield drilling. By effectively separating solids, minimizing waste, and recycling drilling fluids, shale shakers promote cleaner and more sustainable operations.

As a reliable solids control equipment manufacturer, TR Solids Control continues to deliver advanced shale shakers and mud recycling systems that help customers meet both operational and environmental goals — contributing to a greener and more efficient future for the drilling industry.