Solids Control Equipment Models Explained – Guide to Efficient Drilling Mud Treatment Systems

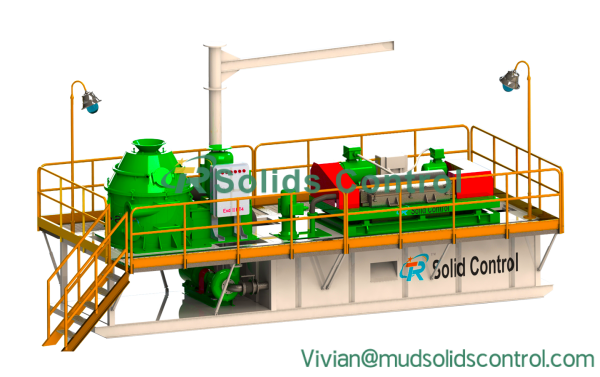

In oil and gas drilling, solids control equipment maintains fluid quality and boosts efficiency; understanding its models helps contractors choose the right system for cost-effective performance. China-based professional manufacturer TR Solids Control provides complete solids control systems and various models for reliable drilling mud treatment.

1. Overview of Solids Control System

A complete solids control system is composed of several main units that work together to remove solids from the drilling fluid. The major components include:

- Shale Shaker: The first-stage equipment for coarse solids removal.

- Desander and Desilter: Used for secondary and tertiary separation of fine solids.

- Decanter Centrifuge: Handles ultra-fine particles and ensures clean fluid recycling.

- Vacuum Degasser: Removes gas bubbles from the mud.

- Mud Agitator & Mud Tank: Keep the drilling fluid evenly mixed and stored.

Each of these units has different models designed for specific drilling capacities and mud conditions.

2. TR Solids Control Equipment Models

TR Solids Control provides a wide range of solids control equipment models, covering every stage of mud processing.

- Shale Shaker Models:TRZS703 Linear Motion Shale Shaker:3-panel design, 240 m³/h capacity, suitable for oilfield and HDD projects.TRZS584 Linear Motion Shale Shaker:4-panel design, compact size, efficient solids separation for smaller rigs.

- Desander Models:TRCS250-2S Desander:Equipped with two 10″ hydrocyclones, ideal for medium-capacity mud systems.TRCS300-3S Desander:Larger flow rate, used in high-volume drilling operations.

- Desilter Models:TRCN100-8N Desilter:8 cones (4″), excellent for removing fine solids below 20 microns.TRCN150-12N Desilter:12 cones (4″), higher efficiency for continuous drilling fluid treatment.

- Decanter Centrifuge Models:TRLW355×1250 Centrifuge:Standard oilfield model with adjustable speed and high separation precision.TRLW450×1000 Centrifuge:Compact structure and stable operation for environmental and HDD use.

- Vacuum Degasser Model:TRZCQ270 Vacuum Degasser:Removes entrained gas to protect pumps and improve fluid stability.

3. Choosing the Right Solids Control Equipment Model

Selecting suitable solids control equipment models depends on multiple factors such as:

- Mud properties (viscosity, density, and solids content).

- Drilling depth and rig size.

- Desired flow rate and separation accuracy.

- Available space and installation layout.

TR Solids Control engineers provide professional recommendations and customized system designs to ensure optimal mud processing performance.

4. Advantages of TR Solids Control Equipment

- Durable materials and corrosion-resistant coating.

- Modular design for easy assembly and transport.

- Energy-efficient motors and low noise operation.

- Quick maintenance and convenient spare parts supply.

- Widely used in oilfield drilling, HDD, CBM, and geothermal projects.

Our products have been exported to more than 40 countries, earning recognition for stable quality and competitive pricing.

5. Conclusion

Understanding solids control equipment models is essential for building an efficient and reliable drilling fluid treatment system. Whether you need a high-capacity shale shaker, precision centrifuge, or a complete solids control solution, TR Solids Control provides the right model to meet your operational requirements.

Leave a Reply