Understanding Shale Shaker Screen Material and Its Impact on Drilling Efficiency

In oil and gas drilling, the shale shaker (first-stage solids control core) relies heavily on screen material—right selection boosts filtration accuracy, durability, and drilling efficiency. China-based TR Solids Control provides high-quality shaker screens with advanced materials for optimal separation and long service life in oilfield projects.

1. What Is Shale Shaker Screen Material?

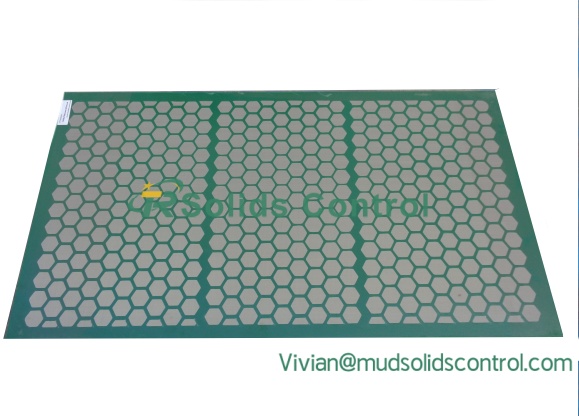

Shale shaker screen material (metal mesh + supporting structure) filters drilling cuttings from circulating mud. Designed to withstand vibration, corrosion, and high flow in harsh conditions, it dictates filtration precision, wear/corrosion resistance, strength, flow capacity, and service life. High-quality screens maintain mud properties, reduce fluid loss, and enhance drilling performance.

2. Common Types of Shale Shaker Screen Materials

Different drilling environments require specific screen materials to achieve optimal separation. The main materials used in drilling shale shaker screens include:

- Stainless Steel Wire Mesh:Widely used (SS304/316/316L), offering corrosion/tensile/wear resistance. Suitable for water/oil-based mud. TR Solids Control weaves fine stainless steel into multi-layer screens for precise separation and long service life.

- Composite Material Frame:Combines high-strength polymer + stainless steel mesh. Lightweight, rust-free, impact-resistant, easy to handle. Ideal for offshore/high-humidity environments; absorbs vibration and reduces screen damage.

- Carbon Steel/Galvanized Frame:Cost-effective with high rigidity for standard applications. Requires galvanizing/epoxy coating to prevent corrosion. Suitable for land drilling with moderate conditions.

- Polyurethane Screens (Optional):For coarse screening or abrasive formations. Offers excellent abrasion resistance and flexibility; ideal for high-solids mud.

3. Screen Layer Configuration

Shale shaker screens use 2–3 layers for balanced strength and separation: top (fine mesh, precision), middle (structural stability), bottom (backing mesh, protection/even vibration). TR Solids Control uses high-temperature bonding for strong interlayer adhesion and consistent screen performance.

4. How Material Quality Affects Drilling Performance

- Higher solids removal efficiency and cleaner drilling mud.

- Reduced fluid loss and lower mud cost.

- Extended screen life and fewer replacements.

- Improved drilling rate and equipment reliability.

Inferior materials may cause frequent screen damage, poor filtration, or fluid leakage, leading to increased downtime and maintenance costs.

5. TR Solids Control Shale Shaker Screen Features

- As a professional manufacturer, TR Solids Control provides shale shaker screens compatible with major brands such as Derrick®, Swaco®, and Brandt®.

- Stainless steel mesh (SS304 / SS316L) for corrosion resistance.

- Composite frame design for lightweight durability.

- CNC laser cutting for high precision and consistent quality.

- API RP13C compliance for mesh size and performance standards.

- Each screen is tested for tension strength, permeability, and wear resistance before delivery.

6. Conclusion

The shale shaker screen material plays a decisive role in solids control efficiency, maintenance cost, and overall drilling performance.By selecting high-quality stainless steel mesh and composite frame screens from TR Solids Control, drilling operators can achieve stable operation, cleaner drilling mud, and longer service life.Whether for land rigs or offshore platforms, TR provides reliable screen materials and customized solutions to meet your project needs.

Leave a Reply