Essential Shale Shaker Maintenance Methods for Reliable Drilling Operations

The shale shaker—critical for solids control—handles first-stage cuttings-mud separation, directly impacting drilling efficiency and fluid quality. Correct maintenance and regular inspections prevent costly downtime and extend the lifespan of screens, motors, and the shaker body.

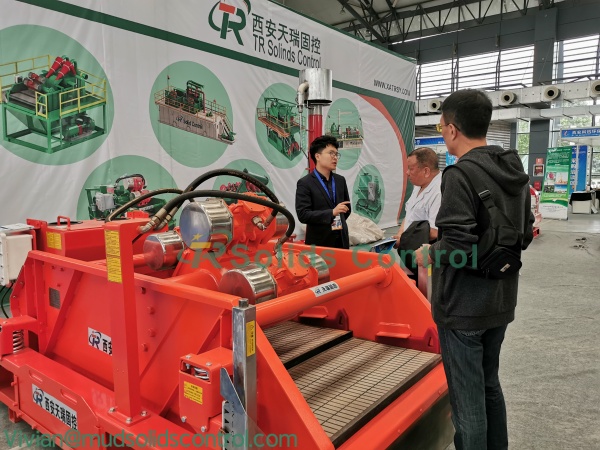

China-based experienced manufacturer TR Solids Control offers high-quality shale shakers and proven maintenance practices for stable performance in harsh field conditions.

1. Daily Maintenance of Shale Shaker

- Check the screen surface: Remove accumulated cuttings or mud to prevent clogging and ensure proper fluid flow.

- Inspect screen tension: Make sure the screens are evenly tightened. Loose screens can cause vibration noise and reduce separation efficiency.

- Monitor vibration motors: Ensure motors are running smoothly without unusual noise or overheating.

- Check fasteners: Tighten bolts on the shaker deck, motor base, and screen frame regularly to prevent loosening due to vibration.

- Inspect the rubber springs and seals: Replace damaged vibration isolators or sealing gaskets promptly.

- Clean the collection box and mud discharge ports: Avoid solid build-up that could affect flow and performance.

2. Screen Replacement and Care

- Stop the shaker and disconnect the power before replacement.

- Remove used screens carefully to avoid damaging the supporting frame.

- Clean the deck surface thoroughly before installing new screens.

- Ensure correct alignment and tight sealing to prevent fluid bypass.

Use TR composite frame screens, which provide longer life and better resistance to corrosion and high temperature.

- Avoid washing with high-pressure water jets directly on the mesh surface.

- Store spare screens in dry, flat conditions.

- Use the proper mesh size for the drilling stage to avoid overloading the screen.

3. Vibration Motor Maintenance

- Keep the motor housing clean and free from mud or oil.

- Check bearing temperature during operation; it should not exceed 75°C.

- Re-grease bearings every 300–500 working hours.

- Make sure both vibration motors rotate in opposite directions to balance motion.

- Replace bearings immediately if abnormal vibration or noise occurs.

- Using original TR vibration motors ensures stable performance, long service life, and energy efficiency.

4. Storage and Long-Term Maintenance

- Clean all mud and solids thoroughly.

- Remove and store screens separately.

- Cover the equipment to prevent dust and moisture.

- Rotate vibration motors manually every two weeks to prevent bearing corrosion.

Before restarting after long-term storage, recheck all electrical and mechanical connections.

5.Conclusion

Following correct shale shaker maintenance methods is essential for achieving continuous and efficient drilling operations. Regular inspections, timely lubrication, and proper screen management significantly reduce downtime and extend equipment lifespan.

With its advanced design, durable components, and professional after-sales service, TR Solids Control stands out as a trusted partner in global solids control solutions.

Leave a Reply