Shale Shaker and Drilling Fluids Systems

In oil and gas drilling, shale shakers and drilling fluid systems form the core unit of solids control systems. As the primary drilling fluid treatment equipment, shale shakers separate cuttings and large solid particles from drilling fluid—ensuring stable drilling fluid properties and creating favorable conditions for downstream solids control equipment. Proper configuration of shale shakers and drilling fluid systems is key to boosting drilling efficiency and controlling operational costs.

During the circulation process, drilling fluid continuously carries formation cuttings back to the surface. If not treated in time, this can adversely affect the performance of the drilling fluid. In the drilling fluid system, the Shale Shaker primarily serves the following functions:

- – Achieve primary solid-liquid separation of the drilling fluid

- – Reduce the solid content in the drilling fluid

- – Alleviate the load on downstream equipment such as sand traps and mud cleaners

- – Improve the reusability of the drilling fluid

Through efficient screening, the Shale Shaker helps maintain stable operation of the drilling fluid system.

In a drilling fluid system, the configuration of the Shale Shaker directly affects the overall solids control performance:

- Screen configuration: Different screens are required for different drilling stages

- Processing capacity: Must meet the circulation flow requirements of the drilling fluid

- Vibration mode: Linear vibrating screens are commonly used for high-volume drilling operations

- Installation and maintenance: Proper installation and regular maintenance help ensure stable system operation

Reasonable configuration helps improve the overall efficiency of the drilling fluid system.

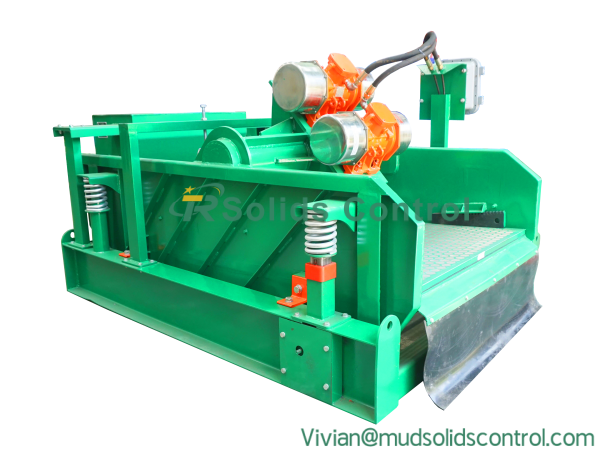

As a professional solid control equipment supplier in China, TR Solid Control has long provided shale shakers and related solid control equipment for drilling fluid systems. TR Solid Control focuses on the following aspects in product design:

- – Equipment structural strength and durability

- – Vibration system operational stability

- – Ease of screen replacement

- – Compatibility with the complete drilling fluid system

Its shale shaker products have been applied in various oil and gas drilling and engineering drilling projects.

With the continuous development of drilling technology, Shale Shakers and drilling fluid systems are also showing new trends:

- – Shaker designs with higher processing capacity

- – More durable screen materials

- – Synergistic operation with automated drilling fluid systems

- – Ongoing improvements in environmental protection and on-site management requirements

These changes are driving the solid control systems toward more stable and efficient development.

Overall, shale shakers and drilling fluid systems play a vital role in drilling solids control processes. With proper selection and standardized operation, shale shakers effectively ensure drilling fluid performance and solids control system stability. Coupled with the mature products and technical support from TR Solids Control, they deliver reliable drilling fluid treatment solutions for drilling projects.

Leave a Reply