Shale Shaker – Efficient Mud Control Solutions

The Shale Shaker is the core link in the oil and gas drilling mud processing system. It is mainly used to screen and separate cuttings and solid particles in the drilling fluid. Through reasonable vibration parameters and screen configuration, the Shale Shaker can improve the recycling rate of drilling fluid and reduce the overall drilling cost while ensuring stable mud performance.

In actual drilling operations, the mud first enters the shale shaker system after returning from the wellhead. The Shale Shaker uses the excitation force generated by the vibration motor to cause the mud to form continuous motion on the screen. The liquid phase enters the mud tank through the screen, while the solid phase particles are transported to the slag discharge port to achieve primary solid-liquid separation.

The Shale Shaker operates based on the vibrating screening principle and mainly includes the following aspects:

- Vibration system: dual vibration motors operate synchronously to form a stable vibration trajectory

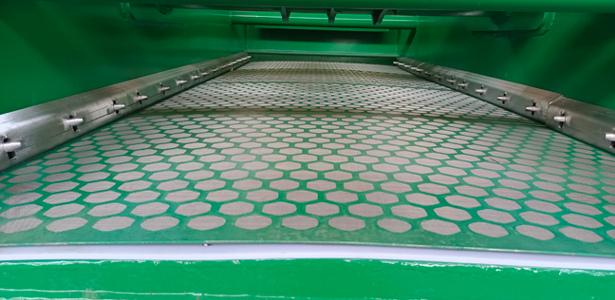

- Screen system: Screens with different mesh sizes are suitable for various drilling conditions

- Screen box structure: Reasonable angle design facilitates cuttings transportation and deliquification

- Shock absorbing device: Reduce the impact of equipment operation on the infrastructure

Through these structures working together, the Shale Shaker can continuously and stably complete the primary purification of drilling fluids.

In drilling operations, the use of Shale Shake can bring practical value in many aspects:

- Improve solid control efficiency: separate large solid particles in a timely manner to reduce the burden on subsequent equipment

- Protect drilling fluid performance: reduce mud pollution and facilitate well wall stability

- Reduce operating costs: extend the life of drilling fluids and downstream solids control equipment

- Adaptable to a variety of working conditions: can be used in oil and gas drilling, directional drilling, geothermal drilling and other scenarios

As one of China’s professional solids control equipment suppliers, TR solids control equipment has long been focused on the development and application of Shale Shaker. The drilling shale shakers produced by TR Solid Control Equipment focus on on-site adaptability in terms of structural design, vibration system configuration and screen compatibility, and can be configured and adjusted according to different drilling fluid performance and processing capacity requirements.

In multiple oil and gas drilling projects, the Shale Shaker mud control solution provided by TR Solid Control Equipment has been successfully used in the mud solid-liquid separation process, providing reliable support for the continuity and stability of drilling operations.

Overall, the Shale Shaker mud control solution plays a basic and key role in the drilling solids control system. Through reasonable selection, standardized installation and scientific maintenance, shale shaker equipment can continue to provide stable mud purification effects for drilling operations. Combined with the engineering experience of TR solids control equipment, Shale Shaker mud control solutions are constantly meeting the actual needs of diverse drilling conditions.

Drilling Fluid Shale Shaker Manufacturer

In modern drilling engineering, the drilling fluid shaker is one of the key equipment in the solids control system. The shale shaker is mainly used for primary solid-liquid separation of drilling fluids, effectively removing drilling cuttings and larger solid particles, and creating stable working conditions for subsequent solid control equipment. TR Solids Control Equipment has long been focusing on the field of drilling fluid treatment and is committed to providing reliable shale shaker solutions for different working conditions.

As the first treatment equipment of the solid control system, the main functions of the shale shaker include:

- Separating cuttings and large solids from drilling fluids

- Reduce the load on drilling fluid circulation system

- Reduce mud loss and improve recycling rate

- Provide stable inlet conditions for desanders, desilters, centrifuges and other equipment

Drilling Fluid Shale Shaker Manufacturer usually designs the equipment structure and parameters according to the drilling depth, mud performance and processing capacity requirements.

The drilling fluid is evenly distributed in the screen box through the feeding device. Under the action of the exciting force generated by the vibration motor, the screen box vibrates regularly.

- The liquid phase enters the mud tank through the screen

- The solid particles move forward along the screen surface and are discharged

The mesh number of the screen, the vibration mode and the angle of the screen box jointly determine the separation effect. TR solids control equipment is designed with vibration stability and screen compatibility in mind to accommodate a variety of drilling fluid systems.

Common shale shaker types include:

- Linear motion shale shaker: suitable for drilling fluids with large processing capacity

- Elliptical motion shale shaker: taking into account conveying speed and screening effect

- Double-Deck Shale Shaker: improve screening efficiency and suitable for complex working conditions

Drilling Fluid Shale Shaker Manufacturer will provide different configuration solutions according to site needs to meet the applications of land drilling and offshore platforms.

When choosing a Drilling Fluid Shale Shaker Manufacturer, focus on the following:

- Equipment structural strength and service life

- Screen specifications and convenience of replacement

- Vibration motor stability

- Spare parts supply and technical support capabilities

TR solid control equipment pays attention to quality control during the production process and provides comprehensive technical support and after-sales service to help users maintain long-term stable operation of the equipment.

As an important piece of equipment provided by Drilling Fluid Shale Shaker Manufacturer, the shale shaker plays a basic and critical role in the drilling solids control system. Through reasonable selection and standardized use, shale shaker can effectively improve mud treatment efficiency. TR solid control equipment will continue to focus on drilling fluid processing needs and provide users with stable and practical solutions for vibrating screens and supporting solid control equipment.

Shale Shakers | Solid Separation Solution

Shale Shakers is a commonly used mud treatment method in oil and gas drilling, geothermal drilling and engineering drilling. As the first treatment equipment of the solid control system, the drilling shale shaker uses the principle of vibration screening to effectively separate cuttings and solid particles in the drilling fluid, providing a stable foundation for subsequent mud circulation and processing. TR solid control equipment has accumulated rich experience in this field and can provide reliable vibrating screen solutions for different working conditions.

During drilling operations, drilling fluid will continuously carry cuttings back to the surface. If the solid phase material is not separated in time, it will directly affect the drilling fluid performance and increase operating costs.

Shale Shakers mainly perform the following functions:

- Preliminary separation of large solids in drilling fluids

- Reduce the processing load of subsequent desanders and desilters

- Reduce drilling fluid consumption and improve recycling rate

- Improve overall operational efficiency on the drilling site

Shale Shakers rely on the excitation force generated by the vibration motor to cause the screen box and screen to vibrate regularly:

- Drilling mud enters the screen box through the feed port

- The liquid phase flows into the mud tank through the screen

- Solid particles are transported and discharged on the screen surface

- Achieve continuous and stable solid-liquid separation process

TR solid control equipment fully considers the properties of different drilling fluids in terms of vibration structure design and screen matching to ensure a stable and reliable separation process.

In practical applications, the effectiveness of Shale Shakers solid-liquid separation solutions is affected by many factors:

- Screen mesh size and screen material

- Vibration mode (linear vibration, elliptical vibration, etc.)

- Treatment capacity and drilling fluid viscosity

- Vibration motor power and exciting force

- Screen box angle and pulp distribution method

Properly matching these parameters will help improve the overall solids control system operation effect.

Shale Shakers are not only suitable for oilfield drilling, but also for:

- Natural Gas and Shale Gas Drilling

- Horizontal Directional Drilling (HDD) Engineering

- Geothermal drilling project

- Industrial mud and environmental protection treatment system

TR Solids Control Equipment focuses on the R&D and manufacturing of drilling solids control equipment, and its Shale Shakers products are widely used in oil and gas drilling, engineering drilling and environmentally friendly mud treatment projects.

By optimizing the vibration structure, improving the service life of the screen and focusing on the convenience of equipment maintenance, TR solid control equipment provides customers with stable and practical solid-liquid separation solutions.

As the core equipment in the drilling solids control system, Shale Shakers play an important role in improving drilling fluid utilization and ensuring the continuity of drilling operations. Combined with reasonable selection and standardized operation, and with the professional products and technical support provided by TR solid control equipment, it can effectively meet the solid-liquid separation needs of different drilling projects.

Shale Shaker: Core Support for Drilling Solids Control

In drilling operations, the core supportive role of the Shale Shaker in the drilling solids control system has been increasingly recognized. As the first processing equipment in the solids control system, the Shale Shaker is primarily used for the primary separation of cuttings and solid particles from the drilling fluid, providing stable and controllable operating conditions for subsequent solids control equipment, and is an important component for ensuring the reuse of drilling fluid and drilling efficiency.

Shale Shaker, also known as mud shale shaker, its main functions include:

- Remove larger solid particles from drilling fluids

- Reduce sand content in drilling fluid

- Reduce the load on subsequent equipment such as mud cleaner and centrifuges

- Improve drilling fluid reuse rate

In the entire drilling solid control process, the operating status of the Shale Shaker directly affects the overall separation effect of the system, so it is regarded as the basic support equipment of the solid control system.

The brief overview of the working principle of a Shale Shaker. Shale Shaker uses the excitation force generated by the vibration motor to cause the screen box to drive the screen mesh to vibrate regularly:

- Drilling fluid is evenly distributed to the screen surface through the feed box

- The liquid phase enters the mud tank through the screen

- Solid particles are transported forward and discharged under the action of vibration

- Complete solid-liquid primary separation

Screen mesh number, vibration intensity and screen box angle are important factors affecting the separation effect.

Shale Shaker core supporting value in solids control systems

- Stable solids control system operation: shale shaker provides cleaner and more stable mud conditions for subsequent equipment and avoids overloading the system.

- Control drilling costs: helps control overall drilling operating costs by reducing mud losses and equipment wear.

- Improve the continuity of drilling operations: stable screening performance can reduce unplanned shutdowns and improve construction efficiency.

As one of the professional solid control equipment suppliers in China, TR Solid Control Equipment has accumulated rich experience in Shale Shaker design and manufacturing:

- Reasonable structural design, suitable for different drilling conditions

- Supports a variety of screen specifications for easy on-site adjustment

- Stable operation, easy maintenance and screen replacement

- Can be well matched with the entire solid control system

The Shale Shaker provided by TR Solids Control Equipment is widely used in oil and gas drilling, directional drilling, environmentally friendly mud treatment and other fields.

Overall, the core supporting role of shale shaker in the drilling solids control system is reflected in the stability of the solids control process, separation efficiency and cost control. Through reasonable selection and standardized use, Shale Shaker can effectively improve the overall performance of the drilling solids control system. Combined with the mature product solutions of TR solid control equipment, it can provide more stable and reliable solid control support for drilling projects.

Key Factors Influence Drilling Shale Shaker Performance

In oil and gas drilling solid control systems, shale shaker performance directly affects mud recovery efficiency, drilling costs, and the operation of subsequent solid control equipment. As the first process in the mud handling system, the separation capability and operational stability of the drilling shale shaker are influenced by various factors. Understanding the key factors that affect shale shaker performance helps in making informed equipment selection on-site, as well as in scientific operation and maintenance.

Vibration parameters are the core factors determining the performance of a shale shaker, mainly including:

1. Vibration type. Common types of vibrating screens include:

Linear vibrating screens have strong conveying capacity and processing capability, making them suitable for high-discharge drilling conditions, and they are widely used at most oilfield sites.

2. Vibration intensity (G-force). Appropriate vibration intensity helps to:

- Improve solid-liquid separation efficiency

- Accelerate the transport speed of cuttings

- Reduce screen surface blockage

In the design of shale shakers in TR solid control equipment, the vibration motor parameters are reasonably matched to ensure stable operation under different working conditions.

The screen is a component directly involved in the separation process, and its configuration significantly affects shale shaker performance.

1. Screen mesh selection: Too low a mesh count results in insufficient solid separation; too high a mesh count can easily clog the screen and reduce processing capacity. It is necessary to match it appropriately according to the properties of the drilling fluid and the drilling stage.

2. Screen structure and material: Composite frame screens are gradually becoming the mainstream choice in practical applications due to their high strength, long service life, and easy replacement. TR Solid Control equipment can provide screens in various specifications to meet the needs of different shaker models.

Impact of Operating and Installation Conditions

- 1. Vibration Screen Installation Angle: A reasonable screen box angle can improve cuttings discharge and increase screening efficiency.

- 2. Uniformity of Slurry Distribution: Uneven slurry flow can cause local screen overload, affecting the overall shale shaker performance.

- 3. Routine Maintenance: This includes checking the vibration motor, the tension of the screens, and the condition of the shock-absorbing springs. Proper maintenance helps ensure long-term stable operation of the equipment.

A reasonable selection helps improve screening efficiency and reduce operating costs.

From a long-term operational perspective, a shale shaker’s structural design and manufacturing quality are fundamental to its performance. As a professional Chinese solid control equipment supplier, TR Solid Control Equipment prioritizes structural strength, durability, vibration system stability, and screen compatibility in its shale shaker manufacturing. Its shale shaker products are widely applied in oil and gas drilling and related solid control fields.

Shale shaker performance is affected by multiple factors, including vibration parameters, screen configuration, operating conditions, and equipment design. Only through proper selection, rational operation, and standardized maintenance can drilling shale shakers achieve stable and efficient separation. With scientific configuration and reliable equipment support, they will continue to play a key role in the entire drilling solids control system.

Shale Shakers and Screens for Drilling Solids Control

In the process of oil and gas drilling, shale shakers and screens are indispensable core equipment and key components in the solids control system. Drilling shakers perform primary separation of cuttings and solid particles in the drilling fluid through screens, directly affecting the subsequent mud purification efficiency, equipment operational stability, and drilling cost control.

Shale shakers are the first processing equipment in the drilling solid control system, mainly used to separate drill cuttings from the drilling mud. Screens are the core consumable components of the shaker, and their structure and mesh specifications directly determine the screening effectiveness. In actual drilling operations, the shaker and screens usually work together as an integrated system to complete the primary purification of the drilling mud.

The main functions of a drilling vibrating screen include:

- – Separating large solid particles from the drilling fluid

- – Reducing the sand content and solid load of the mud

- – Relieving the working pressure on desanders, desilters, and centrifuges

- – Improving the reuse rate of drilling fluid

A stably operating shale shaker helps maintain mud performance and prolongs the service life of drill bits and pump equipment.

Depending on the structure and usage scenarios, common vibrating screen meshes include:

- Composite frame screen: lightweight, corrosion-resistant, easy to replace, with strong sealing

- Stainless Steel screen: high structural strength, suitable for high vibration conditions, with relatively stable service life

Mesh sizes generally range from API 20 to API 325, and users can select according to formation conditions, mud properties, and processing volume.

When selecting shale shakers and screens, it is recommended to focus on the following factors:

- – Matching the drilling fluid flow rate with the processing capacity

- – Vibration mode (linear motion or elliptical motion)

- – Screen compatibility specifications and installation method

- – Performance and structural stability of the vibration motor

- – Ease of on-site maintenance and replacement

A reasonable selection helps improve screening efficiency and reduce operating costs.

As a professional solid control equipment supplier in China, TR Solid Control Equipment has long focused on the design and manufacture of shale shakers and matching screens. TR offers a variety of drilling shaker and screen solutions, widely used in onshore drilling, offshore platforms, and trenchless engineering projects.

TR Solid Control Equipment emphasizes structural stability, screen compatibility, and on-site practicality, and is able to provide customers with suitable solid control configuration recommendations based on different operating conditions.

Shale shakers and screens play a fundamental and crucial role in the solid control system of drilling. By reasonably selecting the type of shaker and screen, not only can the efficiency of mud processing be improved, but the overall drilling operation process can also be optimized. With the development of drilling technology, the structure and performance of shakers and screens are continuously being optimized, and their application value will continue to increase.

Shale Shakers: Efficient Equipment for Drilling Operations

In modern drilling engineering, shale shakers have become an indispensable part of the solid control system. Shale shakers are mainly used for the solid-liquid separation in drilling fluids, removing cuttings and large solid particles through vibration screening, providing stable and clean mud conditions for subsequent solid control equipment, thereby ensuring the continuity and safety of drilling operations.

Shale shaker is usually installed at the front end of the drilling fluid circulation system and is the first treatment equipment in the solid control process. Its main functions include:

- separating drill cuttings and large solid particles from the drilling fluid;

- reducing the solid content of the drilling fluid and improving rheological properties;

- alleviating the processing load on desanders, desilters, and centrifuges;

- reducing mud waste and improving the reuse rate of drilling fluid.

For these reasons, shale shakers are widely used in oil, natural gas, and geothermal drilling operations.

The shale shaker generates regular vibrations through a vibrating motor, causing the screen box to move the screen at high speed. When the drilling fluid enters the screen surface from the feed inlet, the liquid phase passes through the screen into the mud tank, while the solid phase is retained on the screen surface and discharged along the direction of vibration. Different screen sizes and vibration modes can be adapted to various well conditions and mud performance requirements.

In drilling operations, a stably operating shale shaker helps to:

- increase drilling speed and reduce non-productive time,

- control drilling fluid costs,

- reduce equipment wear and maintenance frequency,

- improve cleanliness and environmental performance at the work site.

Therefore, choosing the right shale shaker has a direct impact on the overall efficiency of drilling.

In actual drilling operations, when selecting a shale shaker, the focus should be on:

- whether the processing capacity matches the on-site circulation volume;

- the type of vibration (linear, elliptical, etc.);

- screen specifications and compatibility;

- equipment maintenance and spare parts availability.

Reasonable selection helps to fully leverage the efficiency advantages of the shale shaker in drilling operations.

As a mature solid control equipment supplier in China, TR Solid Control Equipment has long focused on the research and manufacturing of shale shakers and supporting solid control systems. TR shale shakers feature a stable structure, easy screen replacement, and strong adaptability, meeting the needs of mud handling under various drilling conditions, and have been applied in numerous domestic and international drilling projects.

In summary, shale shakers are not only the fundamental equipment of drilling solid control systems but also a crucial part in ensuring drilling efficiency and mud quality. Through scientific selection and standardized use, shale shakers can consistently provide stable and reliable separation during drilling operations. TR solid control equipment will continue to offer professional vibrating screens and comprehensive solid control solutions for the drilling industry.

Shale Shaker Benefits in Drilling Applications

In oil and gas drilling, shale shakers are indispensable solid control devices that directly impact drilling mud purification and overall construction progress. As the first solid control barrier, they use optimized vibration frequencies and screen designs to efficiently separate cuttings, sand, and other solid particles from drilling mud—ensuring stable circulating mud performance and laying the foundation for smooth drilling. Suitable for onshore and offshore operations alike, shale shakers reduce equipment wear from solids, minimize mud waste, boost drilling fluid recycling rates, and meet the oil and gas industry’s dual demands for efficiency and cost control.

1.Optimise drilling mud performance to ensure drilling safety

A core function of shale shakers is rapid drilling mud purification: after mud carries cuttings to the surface, shale shakers promptly separate solid impurities, preventing abnormal viscosity/density that risks wellbore collapse or stuck drill pipe. High-quality models adjust vibration parameters to mud characteristics and cuttings size, ensuring efficient solid-liquid separation, preserving mud’s lubrication, cooling, and sand-carrying capabilities, and indirectly extending drilling equipment lifespan by maintaining optimal working conditions for drill bits and strings.

2. Reduce construction costs and improve resource utilisation

In oil and gas drilling, drilling mud materials and equipment maintenance represent significant costs. Shale shakers efficiently separate solid particles, enabling purified mud to be reused in the circulation system—greatly reducing the need for new mud and lowering material consumption costs. Additionally, they minimize wear on key equipment, reducing failure and maintenance frequency, and effectively controlling drilling costs through both material and maintenance savings.

3. Adapt to complex drilling scenarios and enhance operational stability

Oil and gas fields feature diverse geological conditions, with varying cuttings characteristics and mud types. High-quality shale shakers offer strong adaptability: interchangeable screens of different apertures, plus adjustable vibration amplitude and frequency, enable them to meet solid-liquid separation needs across geological conditions. Whether drilling in complex formations or operating in high-temperature, high-pressure environments, they deliver consistent separation performance, ensuring drilling continuity and minimizing interruptions from inadequate solid control.

4.Supporting environmental compliance and reducing environmental impact

During oil and gas drilling, improperly disposed waste mud can pollute surrounding soil and water. Shale shakers efficiently separate solid particles, allowing purified mud to be recycled, thereby reducing waste mud discharge; meanwhile, the separated cuttings can be dried and further recycled or properly disposed of, minimizing the negative environmental impact of drilling operations, supporting drilling projects to meet environmental regulations, and achieving green drilling.

Amid the oil and gas drilling industry’s focus on efficiency, safety, and environmental protection, shale shakers are growing in application value. Selecting highly adaptable, efficient shale shakers enhances solids control to keep drilling operations on track, while also driving more value for projects through cost control and environmental compliance. As drilling technology advances, shale shakers will continue to evolve toward intelligence, efficiency, and eco-friendliness, supporting the industry’s high-quality development.

Linear Shale Shaker: Applications and Core Features

The Linear Motion Shale Shaker is a commonly used type of vibrating screen in oil drilling solids control systems, mainly used for the primary separation of solid particles in drilling fluid. Through linear vibration, the equipment can achieve stable screening performance under large processing capacities and is widely used in oil and gas drilling, mud treatment, and related engineering fields.

The Linear Motion Shale Shaker is a mud vibrating screen that adopts a linear vibration trajectory. Driven by two synchronously counter-rotating vibration motors, its screen box moves linearly, pushing drilling cuttings forward while enabling liquid to pass through the screen smoothly. With a robust structure and uniform force distribution, it is ideal for high-flow, high-solid-content drilling mud.

The working process of a Linear Motion Shale Shaker mainly includes the following steps:

– Drilling fluid flows from the stock tank into the shaker basket.

– The vibrating motor generates a linear excitation force.

– The mud moves forward on the screen surface.

– The liquid phase passes through the screen into the lower mud tank.

Solid particles move along the screen surface and are discharged through the cuttings outlet.

This working principle helps improve screening efficiency while reducing the likelihood of screen clogging.

Linear Motion Shale Shakers typically have the following structural features:

– Linear vibration pattern with stable conveying capacity

– Adjustable excitation force to adapt to different working conditions

– Multi-layer screen structure for easy graded screening

– Modular design for convenient maintenance and replacement

This type of shaker demonstrates good adaptability in the treatment of high-density, high-viscosity drilling fluids.

In oilfield drilling operations, the Linear Motion Shale Shaker, as the first piece of equipment in the solids control system, mainly serves to:

– Remove large drill cuttings from the drilling fluid

– Reduce the load on subsequent desanders and desilters

– Improve the circulation performance of the drilling fluid

– Reduce the cost of drilling fluid treatment and disposal

This equipment is suitable for land drilling, offshore platforms, and various types of mud circulation systems.

The Linear Motion Shale Shaker plays an important role in the solid control field of oil drilling due to its stable linear vibration mode and good handling capacity. With proper configuration and standard use, this equipment can effectively improve the purification level of drilling fluid and ensure the continuity and safety of drilling operations.

As a mature solids control equipment supplier in China, TR Solids Control has accumulated extensive experience in the design and manufacture of Linear Motion Shale Shakers. Its products focus on structural stability, vibration system compatibility, and screen mesh compatibility, and can provide customized configuration solutions based on customer operating conditions to meet the needs of different drilling projects.

Drilling Shale Shaker: Applications and Value in Oil-Gas Solids Control

In the process of oil and gas exploration and development, the Drilling Shale Shaker is one of the core pieces of equipment in the drilling solids control system, mainly used for the primary solid-liquid separation of drilling fluid. Through high-frequency vibration and screen filtration, the shaker can effectively separate cuttings and maintain the stability of the drilling fluid.

The Drilling Shale Shaker provided by TR Solids Control is widely used in various types of drilling projects due to its reasonable structural design, stable operation, and adaptability to different working conditions.

Basic working principle of a Shale Shaker: Regular vibrations are generated by a vibrating motor, causing the drilling fluid to form a flow path on the screen surface: drilling fluid passes smoothly through the screen for recovery; solid particles are retained and quickly discharged; reduces the sand content in the drilling fluid; improves the operating conditions of subsequent solids control equipment.

TR Solids Control in the design and application of Drilling Shale Shakers, focuses on equipment stability and practicality, mainly reflected in:

– Multiple mesh configurations to adapt to different drilling fluid systems

– Dual motors or linear vibration structures to ensure screening efficiency

– Adjustable screen box angles to meet different flow and viscosity requirements

– Modular structural design for easy on-site maintenance and replacement

Application Scenarios of Drilling Shale Shaker in Drilling Solid Control Systems

Onshore oil and gas drilling projects

Offshore platform drilling projects

Directional and horizontal well operations

High-circulation drilling fluid handling systems

By properly configuring the Drilling Shale Shaker, the overall efficiency of the solid control system can be effectively improved.

How to Choose the Right Drilling Shale Shaker?

When selecting a model, you can focus on the following factors:

– Drilling fluid handling capacity and flow requirements

– Screen size and ease of replacement

– Vibration type and excitation force parameters

– Stability of continuous equipment operation

– Manufacturer’s technical support and service capabilities

TR solid control equipment can provide various models of Drilling Shale Shakers according to different drilling conditions, meeting the diverse needs of projects.

As an important component of the drilling solid control system, the Drilling Shale Shaker plays a crucial role in ensuring the quality of drilling fluid, reducing equipment load, and improving operational efficiency. With the application experience of TR solid control equipment, it can provide more stable and sustainable solid control solutions for oil and gas drilling projects.