Key Factors Affecting Shale Shaker Price in Solids Control and Drilling Operations

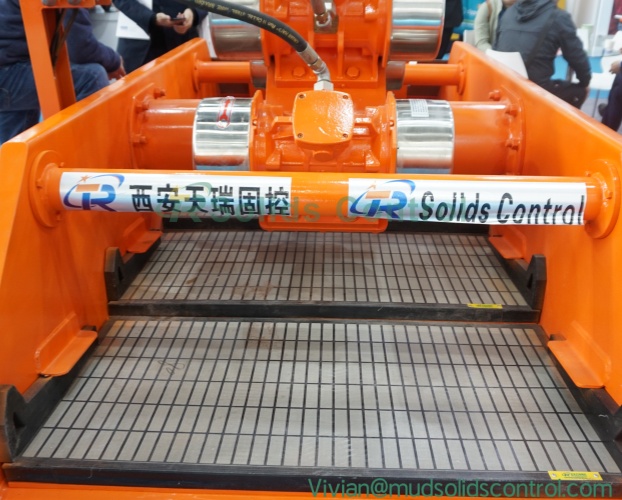

When selecting solids control equipment, understanding the factors affecting shale shaker price helps buyers make better decisions. A shale shaker plays a crucial role in drilling mud separation, and its cost varies depending on structure, performance level, components, and technical support. Below is a detailed explanation of the main elements that influence pricing in the market.

1. Design Type and Motion Mode

Common Designs: Linear motion shale shaker. Balanced elliptical motion shaker

Why it affects price: Linear motion units generally require stronger motors and heavier structures. Elliptical motion units need more precise engineering design.

Shakers with adjustable deck angle, higher G-force, or dual/triple deck configurations increase the price accordingly.

2. Vibration Motor Quality and Power

- Motor brand and origin

- Power rating (e.g., 1.72 kW / 2.2 kW / 2×3.0 kW)

- Protection level (IP55 / IP65 / explosion-proof level)

- Service life and vibration stability

High-quality motors provide stronger vibration, longer operation hours, and lower maintenance cost.

3. Screen Type and Quality

Shaker screens are consumable parts, and their cost directly impacts the overall equipment price.

- Mesh precision

- Frame material

- Layer structure

- API compliance

4. Material and Manufacturing Process

- Carbon steel vs. stainless steel

- Welded vs. laser-cut components

- Rubber springs vs. metal springs

- Coating quality for corrosion resistance

Manufacturers using precision welding, CNC cutting, and high-strength frames will offer more durable shakers but at a higher price range.

5. Processing Capacity and Technical Specifications

Larger and more advanced shale shakers naturally cost more. Bigger capacity means stronger structure and higher power motors, which increases cost.

6. Brand, Service, and Technical Support

Reliable manufacturers offer stronger technical support and spare parts supply. A well-established supplier provides better stability and more professional service, which also reflects in the price.

7. Market Demand and Application Industry

Oilfield-grade equipment often requires higher vibration performance, stronger structure, and better corrosion resistance—leading to higher cost compared to light-duty applications.

Understanding the factors affecting shale shaker price helps buyers choose the right equipment according to their specific needs, application conditions, and budget. Performance, reliability, and long-term maintenance cost should always be considered—not just the initial purchase price.

Leave a Reply