Category Archives: Post

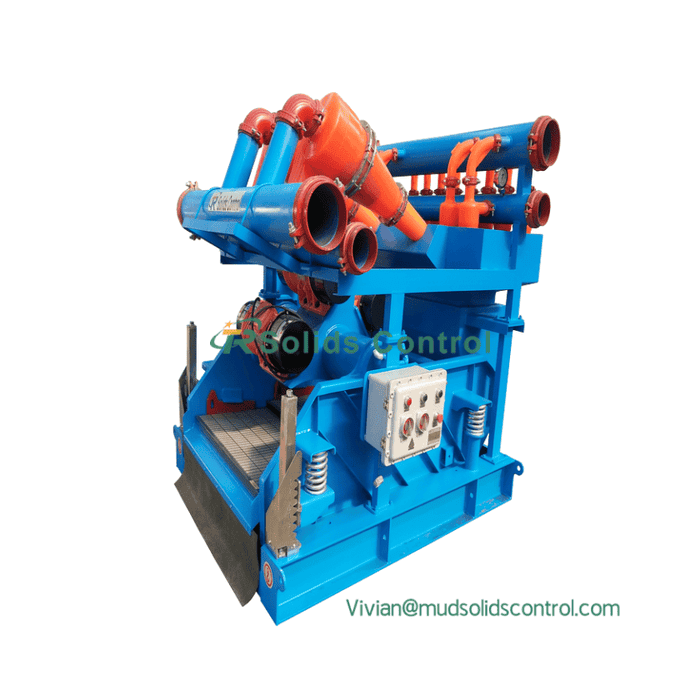

TRQJ200*1S-100*4N Solids Control Mud Cleaner – Integrated Drilling Fluid Purification System

Product Description

The TRQJ200 Solids Control Mud Cleaner is a powerful drilling fluid system. It combines three purification jobs into one simple unit. This single system works as a desander, desilter, and shale shaker. It removes solid waste very effectively. At the same time, it keeps valuable barite in the mud. This smart design fixes issues with older, bulky equipment. It is perfect for oilfield, geothermal, and tunneling projects. Best of all, its strong build handles tough drilling conditions with ease.

Features & Benefits

This Solids Control Mud Cleaner brings many smart benefits. First, it has durable hydrocyclones with a special lining. This lining resists wear and tear. Next, the reinforced sieve box is built for strength and a long life. Additionally, quality vibration motors ensure smooth, powerful operation. You can also adjust the G-force for different mud types. Furthermore, the sieve box has a special heat treatment and anti-corrosion coating. This protects it in harsh conditions. Finally, you get multiple screen options and reliable electrical parts. Together, these features add flexibility and safety.

Technical Advantages

This Solids Control Mud Cleaner offers excellent technical benefits. For example, it captures very fine particles as small as 15-44μm. Its internal design also uses less energy and reduces turbulence. Importantly, it saves barite during the cleaning process. This directly cuts mud costs. Maintenance is also easy due to the modular design. As a result, you can quickly replace hydrocyclones, screens, or motors. Other options include automation and different screen meshes. Moreover, wear-resistant materials mean a longer life and less downtime.

Applications

The Solids Control Mud Cleaner serves many different industries. Primarily, it is used in oil and gas drilling to keep fluids stable. It also works very well in horizontal directional drilling (HDD). Furthermore, it handles high-solid slurries in geothermal and CBM wells. Beyond energy, mining and tunneling projects use it to clean slurry. Lastly, it supports environmental jobs like soil clean-up and waste management.

Advantages & Services

Choosing this Solids Control Mud Cleaner brings many advantages. It cleans better than old equipment and also saves space. Therefore, you will lower your operating costs. You will use less mud and energy. The system is also flexible for different drilling needs. Its strong build and trusted parts ensure reliable performance. We also offer custom setups, fast spare parts, and expert support. Because of this, your operation will run more smoothly.

Why Construction Professionals Choose Solids Control Mud Cleaner ?

Professionals pick the TRQJ200 for its great performance and cost savings. Specifically, it keeps barite and reduces fluid replacement. The sturdy build also lasts in tough conditions. You can even customize it with different cyclone setups and automation. Moreover, global service and support back it up. In conclusion, this machine brings efficiency and reliability to any drilling operation.

About TR SolidsControl

TR SolidsControl is a professional manufacturer of drilling fluid equipment, supplying advanced solids control solutions for oil and gas, trenchless, and geothermal industries worldwide. Our commitment to innovation and quality ensures high-performance products and reliable service.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

TRPZS584 Dual Motion Shale Shaker – High-Capacity Adjustable Solids Control for Drilling Fluids

Product Description

The TRPZS584 Dual Motion Shale Shaker cleans drilling fluids in tough industrial jobs. It removes drill cuttings very well. This shale shaker uses dual vibration technology. As a result, it offers great separation and fluid recovery. It is perfect for oil and gas drilling. Moreover, it works in HDD and mining too. It processes 140 m³/h of fluid. You can adjust its vibration strength up to 8.5G. Therefore, it ensures reliable performance and lower drilling costs.

Features & Benefits

The TRPZS584 Dual Motion Shale Shaker is very versatile. Operators can change vibration intensity easily. They can also adjust screen angles from -3° to +3°. This helps match different site conditions. In addition, its compact design fits in tight spaces. The quick-release wedge system allows fast screen changes. No tools are needed. This reduces downtime a lot. It uses strong Martin or OLI motors. It also has reliable Schneider or Siemens parts. So, this shale shaker lasts long and works safely in tough conditions.

Technical Advantages

This Dual Motion Shale Shaker is built to be reliable and easy to use. It has three motors (1.72kW + 1.72kW + 0.75kW). Together, they power the 2.7 m² screening area very well. The unit is corrosion-resistant. It also meets ExdIIBt4, IECEX, and ATEX explosion-proof standards. Therefore, it is safe in hazardous drilling areas. You can adjust the deck mechanically. It also has high G-force power. This makes it good for thick, dense fluids.

Applications

This Dual Motion Shale Shaker works in many fields. For example, it is used on oil and gas drilling sites. It is also great for horizontal directional drilling (HDD). Besides, mining and mineral processing plants use it too. Furthermore, it works in big construction and tunneling projects. It handles many types of drilling waste. This includes bentonite slurries and oil-based muds. So, it helps recycle fluid, protect the environment, and save equipment.

Advantages & Services

When you choose this Dual Motion Shale Shaker, you get a great balance of quality and cost. We support it with a global supply chain. Also, we offer competitive prices and fast worldwide delivery. Payment terms are flexible. After-sales support is comprehensive. For instance, we provide technical help and training. Spare parts are easy to get. Moreover, this shale shaker works with parts from other major brands. This makes maintenance and mixing easier.

Why Construction Professionals Choose Dual Motion Shale Shaker?

Construction and drilling experts choose this Dual Motion Shale Shaker for its strength and ease of use. It adapts quickly to different ground and fluid types. Therefore, it keeps operations running smoothly. It also cuts fluid loss and meets environmental rules. It is industry-certified and known to last long. Plus, it comes with great service support. Ultimately, it is the top choice for teams that care about productivity, reliability, and total cost.

About TR SolidsControl

TR SolidsControl is a professional manufacturer of drilling fluid equipment, supplying advanced solids control solutions for oil and gas, trenchless, and geothermal industries worldwide. Our commitment to innovation and quality ensures high-performance products and reliable service.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

TRPS584 Elliptical Motion Shale Shaker – High-Capacity Solids Control for Drilling Fluids

Product Description

The TRPS584 Balanced Elliptical Motion Shale Shaker handles tough drilling jobs by cleaning drilling fluid and removing solid cuttings. As a result, it is perfect for oil and gas, HDD, and mining operations. Furthermore, it processes up to 140 m³/h of fluid. You can also adjust its vibration strength up to 7.1G for excellent fluid recovery. Ultimately, its balanced elliptical motion ensures smooth and efficient operation.

Features & Benefits

This Elliptical Motion Shale Shaker is built for high performance. For example, you can adjust the vibration from 0 to 7.1G to handle different materials like sticky cuttings. Moreover, the elliptical motion improves fluid flow and prevents screen clogging. Therefore, screen changes are fast and take under 5 minutes with the wedge-lock system. Additionally, it uses strong Martin or OLI motors that last over 20,000 hours. Finally, you can mechanically adjust the deck angle from -1° to +5° to optimize solids removal for any mud weight.

Technical Advantages

The shaker is built to last in harsh conditions. Specifically, it uses corrosion-resistant Hardox and SS304 steel. Furthermore, its two efficient motors (1.94 kW + 1.0 kW) save energy. The total screen area is a large 2.7 m², using four standard screens. Most importantly, it meets strict explosion-proof standards (ExdIIBt4, IECEX, ATEX) for safety.

Applications

This shaker works in many drilling applications. For instance, it is essential for oil and gas drilling. It is also great for horizontal directional drilling (HDD) and mining. Because it handles high-density fluids so well, it is a key tool for contractors. Therefore, it improves drilling efficiency, cuts costs, and protects the environment.

Advantages & Services

This shale shaker saves money. In fact, it can reduce mud costs by up to 15% through better recovery. Moreover, its strong design needs little maintenance. Similarly, the long-life motors lower your total cost of ownership. Additionally, its compact size makes it easy to install. Finally, we offer full support to keep your operation running.

Why Construction Professionals Choose Elliptical Motion Shale Shaker?

Professionals pick the TRPS584 for its reliability and ease. They also value the ability to make quick adjustments. For example, tool-free screen changes save valuable time. Furthermore, its high capacity keeps projects on schedule. It also meets all safety and environmental rules. In conclusion, with its proven technology, it is a smart long-term investment.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Mud Shale Shaker was Successfully Sent to Egypt

Recently, TR SOLIDS CONTROL, which is highly regarded in the industry, ushered in another important business progress – its independent research and development and production of mud shaker successfully sent to Egypt, which marks TR Solids Control in the international market, especially in the Middle East region of the development of a solid big step.

TR Solids Control has been focusing on the field of mud solid control equipment, with superb manufacturing technology, excellent product performance and strict control of quality, its mud vibrating screen has been recognized and praised by many customers in the domestic market. The slurry shaker sent to Egypt embodies the effort and wisdom of TR Solids Control R & D team, which is a high-performance equipment carefully built for the needs of drilling operations under complex geological conditions.

The mud shale shaker has many outstanding advantages, using advanced vibration technology, can achieve efficient and stable screening effect, ensure that the solid particles in the mud are accurately separated, greatly improve the recycling efficiency of drilling mud, and effectively reduce the wear of drilling equipment, helping drilling operations more smooth and efficient development. In terms of structural design, it is robust and durable, not only easy to install and maintain, but also adapt to a variety of harsh field operating environments, which is one of the important reasons why it is favored by Egyptian customers.

https://youtu.be/ggcgZnWCmxE?si=_INa5u9lW1bcO2JT

The mud shale shaker sent to Egypt is a strong proof that the quality of TR Solids Control products has been recognized by the international market. The relevant person in charge of TR Solids control said that in the future, the company will continue to uphold the development concept of innovation-driven and quality-first, further increase its expansion efforts in the international market, provide more customers around the world with high-quality mud solid control equipment and solutions, and help the global oil drilling and other related industries to flourish.

It is believed that with the use of this batch of mud shaker in Egypt, the brand influence of TR Solids Control will be further enhanced in the Middle East region and even on the broader international stage, opening a new chapter in the development of the company’s overseas business.

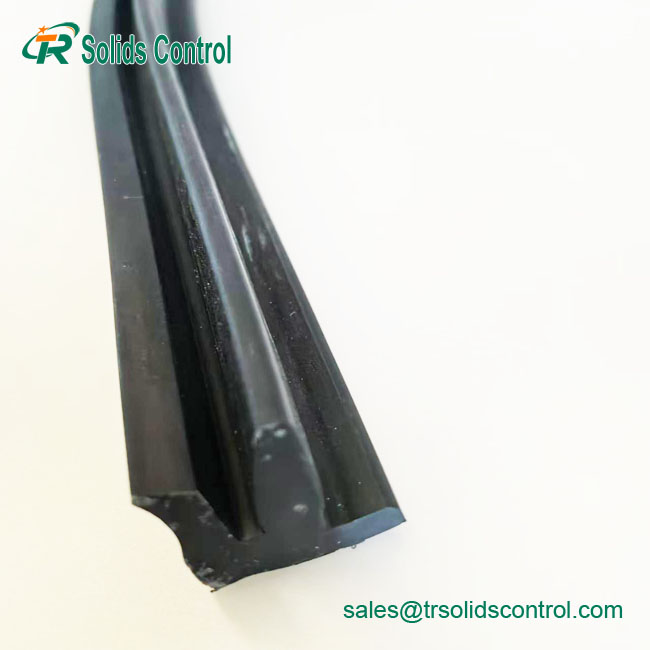

16848-11 Buldhead Protector Double for HyperPool Shakers

The 16848-11 Buldhead Protector Double is engineered with advanced materials that offer superior protection against impacts and abrasions. It is design features double-layered construction. The double-layered construction significantly increases its durability and effectiveness in safeguarding the head.

The role in maintainingthe performance of hyperpool shakers is the 16848-11 Buldhead Protector Double. how it enhances the functionality of hyperpool shakers.

Understanding Hyperpool Shakers

Hyperpool shakers are vital in the drilling process. It is used to separate drilling fluids from cuttings. They ensure that the drilling operation remains efficient by recycling the drilling fluid. It is essential for maintaining pressure and cooling the drill bit. Given the harsh conditions under which these machines operate. It is crucial to equip them with high-quality 16848-11 Buldhead Protector.

The Role of the 16848-11 Buldhead Protector Double

The 16848-11 Buldhead Protector Double is specifically designed to provide enhanced protection for hyperpool shakers. This component acts as a barrier against the abrasive materials and harsh chemicals that are often present in drilling environments. The Buldhead Protector Double helps to prevent wear and tear, ultimately extending the lifespan of the equipment.

Key Features of the 16848-11 Buldhead Protector

1. Durability:

Constructed from high-quality materials, the 16848-11 Buldhead Protector Double is built to withstand extreme conditions. It is robust design ensures that it can handle the abrasive nature of drilling fluids and cuttings.

2. Easy Installation:

The design of the Buldhead Protector Double allows for straightforward installation on hyperpool shakers. This ease of installation minimizes downtime, enabling operators to quickly replace worn components and maintain operational efficiency.

3. Compatibility:

The 16848-11 Buldhead Protector Double is engineered to be compatible with various models of hyperpool shakers. This versatility makes it a preferred choice for many operators looking to enhance their equipment without the need for extensive modifications.

4. Cost-Effectiveness:

Investing in the Buldhead Protector Double can lead to significant cost savings in the long run. By reducing the frequency of repairs and replacements for the shaker. Operators can lower their maintenance costs and improve overall productivity.

The integration of the 16848-11 Buldhead Protector into hyperpool shakers protects the machinery. By ensuring that the shaker operates at optimal performance levels, operators can achieve better separation of drilling fluids and cuttings. This improved efficiency translates to reduced waste and lower operational costs, making it a win-win for drilling operations.

The 16848-11 Buldhead Protector Double is an indispensable component for hyperpool shakers in the oil and gas industry. The importance of high-quality protective components like the Buldhead Protector Double will only grow. hyperpool shakers can meet the demands of modern drilling operations.

Contact us today to learn more about Side Support Rubber and shaker screens, how TR can support your solids control needs with innovative solutions.TR is a professional manufacturer for producing Solids Control System and Solids Control Equipment.If you need mud shale shaker, We will provide the high quality drilling shale shaker and best service. Your best Mud Recycling System start from TR solids control.

16848-11 Buldhead Protector Double

The 16848-11 Buldhead Protector Double is engineered with advanced materials that offer superior protection against impacts and abrasions. It is design features double-layered construction. The double-layered construction significantly increases its durability and effectiveness in safeguarding the head.

The role in maintainingthe performance of hyperpool shakers is the 16848-11 Buldhead Protector Double. how it enhances the functionality of hyperpool shakers.

Understanding Hyperpool Shakers

Hyperpool shakers are vital in the drilling process. It is used to separate drilling fluids from cuttings. They ensure that the drilling operation remains efficient by recycling the drilling fluid. It is essential for maintaining pressure and cooling the drill bit. Given the harsh conditions under which these machines operate. It is crucial to equip them with high-quality 16848-11 Buldhead Protector.

The Role of the 16848-11 Buldhead Protector Double

The 16848-11 Buldhead Protector Double is specifically designed to provide enhanced protection for hyperpool shakers. This component acts as a barrier against the abrasive materials and harsh chemicals that are often present in drilling environments. The Buldhead Protector Double helps to prevent wear and tear, ultimately extending the lifespan of the equipment.

Key Features of the 16848-11 Buldhead Protector

1. Durability:

Constructed from high-quality materials, the 16848-11 Buldhead Protector Double is built to withstand extreme conditions. It is robust design ensures that it can handle the abrasive nature of drilling fluids and cuttings.

2. Easy Installation:

The design of the Buldhead Protector Double allows for straightforward installation on hyperpool shakers. This ease of installation minimizes downtime, enabling operators to quickly replace worn components and maintain operational efficiency.

3. Compatibility:

The 16848-11 Buldhead Protector Double is engineered to be compatible with various models of hyperpool shakers. This versatility makes it a preferred choice for many operators looking to enhance their equipment without the need for extensive modifications.

4. Cost-Effectiveness:

Investing in the Buldhead Protector Double can lead to significant cost savings in the long run. By reducing the frequency of repairs and replacements for the shaker. Operators can lower their maintenance costs and improve overall productivity.

The integration of the 16848-11 Buldhead Protector into hyperpool shakers protects the machinery. By ensuring that the shaker operates at optimal performance levels, operators can achieve better separation of drilling fluids and cuttings. This improved efficiency translates to reduced waste and lower operational costs, making it a win-win for drilling operations.

The 16848-11 Buldhead Protector Double is an indispensable component for hyperpool shakers in the oil and gas industry. The importance of high-quality protective components like the Buldhead Protector Double will only grow. hyperpool shakers can meet the demands of modern drilling operations.

Contact us today to learn more about Side Support Rubber and shaker screens, how TR can support your solids control needs with innovative solutions.TR is a professional manufacturer for producing Solids Control System and Solids Control Equipment.If you need mud shale shaker, We will provide the high quality drilling shale shaker and best service. Your best Mud Recycling System start from TR solids control.

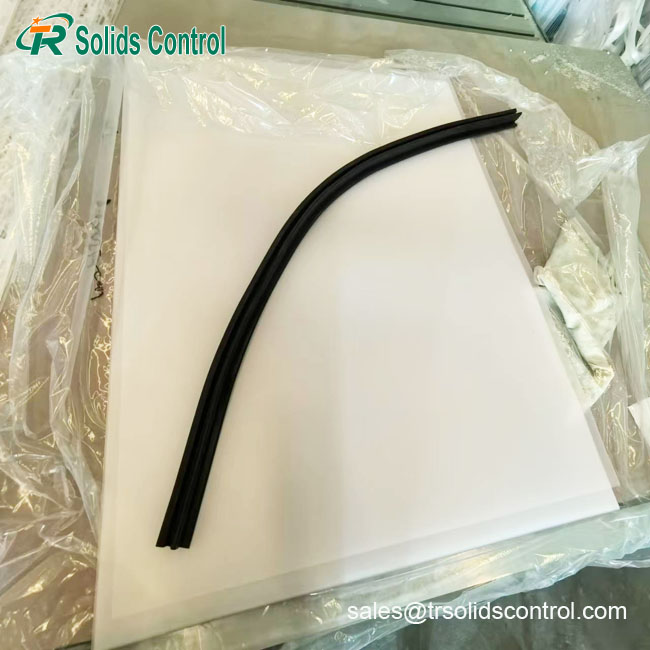

16848-01-001 Side Support Rubber

The importance of the 16848-01-001 side support rubber for hyperpool shaker.This part plays a vital role in ensuring the stability and functionality of various machines, particularly in applications where support and cushioning are necessary.

Understanding the Role of Side Support Rubber

The 16848-01-001 side support rubber is designed to provide essential support to machinery, helping to absorb shocks and vibrations that can occur during operation. This rubber component is typically used in conjunction with other parts to create a stable environment for machinery to function optimally.Its primary purpose is to prevent excessive movement and wear, which can lead to mechanical failure or reduced efficiency.

Key Features of 16848-01-001 Side Support Rubber

- Durability: One of the standout features of the 16848-01-001 side support rubber is its durability. Made from high-quality rubber materials, it is designed to withstand harsh conditions, including extreme temperatures and exposure to various chemicals. This resilience ensures that the component maintains its integrity over time, reducing the need for frequent replacements.

- Shock Absorption: The rubber’s inherent properties allow it to absorb shocks effectively. This is particularly important in applications where machinery experiences constant movement or vibration. By dampening these forces, the side support rubber helps to protect sensitive components from damage, thereby extending the lifespan of the equipment.

- Versatility: The 16848-01-001 side support rubber is versatile and can be used in a wide range of applications. Whether in automotive, industrial, or consumer products, this component can be found in various machines, providing essential support and stability.

- Easy Installation: Another advantage of the 16848-01-001 side support rubber is its ease of installation. Designed to fit seamlessly into existing machinery setups, it can be quickly and efficiently replaced when necessary, minimizing downtime and maintenance costs.

Applications of 16848-01-001 Side Support Rubber

The applications of the 16848-01-001 side support rubber are vast. In the automotive industry, it is often used in suspension systems to provide stability and comfort during driving. In industrial machinery, it can be found in conveyor systems, where it helps to support and stabilize moving parts. Additionally, in consumer products, such as appliances, this rubber component ensures that devices operate smoothly and quietly.

The 16848-01-001 side support rubber is an indispensable component in various machinery and equipment. Its durability, shock absorption capabilities, versatility, and ease of installation make it a preferred choice for manufacturers and maintenance professionals alike. As industries continue to evolve and demand more from their machinery, components like the 16848-01-001 side support rubber will remain crucial in ensuring operational efficiency and longevity. Investing in high-quality side support rubber not only enhances the performance of equipment but also contributes to overall safety and reliability in various applications.

Contact us today to learn more about Side Support Rubber and shaker screens, how TR can support your solids control needs with innovative solutions.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

BM6K80290 SPRING SPOOL PLASTIC for Mongoose Shaker

The BM6K80290 Spring Spool Plastic is an essential component When it comes to enhancing the performance of your Mongoose shaker. The spring spool is designed specifically for Mongoose shakers ensuring optimal functionality.

The BM6K80290 Spring Spool Plastic is crafted from durable materials that provide longevity and reliability.It is robust construction allows it to withstand the rigors of frequent use.

One of the standout features of the BM6K80290 is its lightweight design.The allowing for smooth operation without adding unnecessary weight to your shaker.

BM6K80290 SPRING SPOOL PLASTIC for Mongoose Shaker

nstallation of the BM6K80290 Spring Spool Plastic is straightforward. making it accessible for anyone looking to upgrade their Mongoose shaker. It is functional benefits, the BM6K80290 also adds a touch of professionalism to your shaker.

if you’re looking to enhance your Mongoose shaker’s performance, the BM6K80290 Spring Spool Plastic is a must-have.Its durability, lightweight design, and ease of installation make it an excellent investment for anyone serious about mixology. Upgrade your shaker today and experience the difference!

Contact us today to learn more about Spring Spool Plastic and shaker screens, how TR can support your solids control needs with innovative solutions.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

9671640 Screen Frame Weldment for Mongoose Shaker

One of the critical components that contribute to these factors is the 9671640 screen frame weldment.9671640 screen frame weldment highlighting role in enhancing the performance of the Mongoose shaker.

The Mongoose shaker is a vital piece of equipment used in the drilling process to separate solids from drilling fluids.Its efficient design allows for high-capacity processing, making it a preferred choice in various drilling operations.The shaker ensure that the drilling fluid is clean and reusable, which is essential for maintaining operational efficiency and reducing costs.

The Role of the 9671640 Screen Frame Weldment

The 9671640 screen frame weldment is an integral part of the Mongoose shaker. This component serves as the structural backbone that supports the shaker screens. The weldment is designed to withstand the rigors of drilling operations, including exposure to harsh environments and heavy loads. It is robust construction ensures that it can handle the vibrations generated during the shaking process without compromising its integrity.

The 9671640 screen frame weldment is constructed from high-quality materials that are resistant to wear and tear.

The weldment is manufactured with precision to ensure a perfect fit with the Mongoose shaker.

the 9671640 screen frame weldment can be easily installed or replaced.

Designed for compatibility with the Mongoose shaker.

By providing a stable and secure platform for the shaker screens.The 9671640 screen frame weldment contributes to the overall performance of the Mongoose shaker.

Benefits of Using the 9671640 Screen Frame Weldment

The 9671640 screen frame weldment can lead to significant cost savings over time. It is durability reduces the frequency of replacements.9671640 screen frame weldment efficiency enhances the overall productivity of the drilling operation.

screen frame weldment minimizes the risk of equipment failure.

The 9671640 screen frame weldment is a crucial component that enhances reliability of drilling operations. It is durable construction make it an invaluable asset in the oil and gas industry. The 9671640 screen frame weldment a key player in the future of drilling technology.

Contact us today to learn more about SWACO Spring Coil and shaker screens, how TR can support your solids control needs with innovative solutions.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-18509252400

E-mail:sales@trsolidscontrol.com

www.solidscontrolequipment.com