Category Archives: Post

Buyer’s Guide: Key Features to Look for in a Shale Shaker

Choosing the right shale shaker is crucial for achieving efficient solids control and stable drilling performance. As the first stage of the solids control system, shale shakers remove drill cuttings from drilling mud, protecting downstream equipment and reducing overall operational costs. This buyer’s guide highlights the key shale shaker features you should consider to ensure reliability, efficiency, and value for your drilling operation.

1. Vibration Motion Type

The shaker’s vibration pattern determines solids movement and separation efficiency.

- Linear motion shale shakers: Deliver high G-force and fast cuttings conveyance—ideal for heavy drilling loads.

- Balanced elliptical motion shakers: Provide smoother operation with better fluid recovery for less aggressive drilling.

Select a motion type that best matches your drilling environment and mud properties.

2. Screen Capacity and Design

High-capacity shale shaker screens are essential for effective solids removal. Look for:

- API-certified mesh sizes for accurate particle separation.

- Composite frame screens for durability and corrosion resistance.

- Quick screen replacement systems to reduce downtime and maintenance costs.

3. Adjustable Deck Angle and Vibration Force

A good shale shaker allows you to adjust the deck angle and vibration intensity to adapt to changing drilling conditions. This flexibility improves solids conveyance, prevents screen flooding, and enhances overall mud treatment efficiency.

4. Robust Structure and Materials

Choose a shaker made with high-strength steel and anti-corrosion coatings to withstand harsh drilling environments. A solid construction minimizes vibration fatigue and extends equipment lifespan.

5. Ease of Maintenance

Time is money on a drilling site. Shale shakers with easy-access panels, simple tensioning devices, and modular components help speed up maintenance, reducing downtime and increasing productivity.

6. Energy Efficiency and Noise Control

Modern shakers are designed for lower energy consumption and quieter operation. This not only reduces running costs but also provides a safer and more comfortable work environment.

Conclusion

Selecting the right shale shaker involves more than just comparing prices—it’s about finding a system that balances performance, durability, and cost-effectiveness. By focusing on vibration motion, screen design, adjustability, and ease of maintenance, buyers can ensure optimal solids control and longer equipment life in every drilling operation.

How to Choose the Right Shale Shaker Screen for Your Operation

Selecting the correct shale shaker screen is one of the most important decisions in any drilling operation. The screen directly affects solids control efficiency, drilling fluid quality, and overall equipment performance. With so many screen types and configurations available, understanding how to choose the right shale shaker screen ensures maximum productivity and lower operating costs.

1. Understand Mesh Size and API Rating

Mesh size determines the size of particles that can pass through the screen. Shaker screens are classified using API (American Petroleum Institute) standards, which indicate their separation capability.

- Coarse screens (API 20–80): Used for larger solids in early-stage drilling.

- Medium screens (API 100–150): Suitable for general solids control.

- Fine screens (API 170–325): Used for fine solids and high-performance filtration.

Selecting the proper API size ensures efficient fluid recovery without overloading the system.

2. Choose the Right Screen Type

There are two main shale shaker screen types:

- Steel Frame Screens: Strong and durable, ideal for heavy-duty drilling operations.

- Composite Frame Screens: Lightweight, corrosion-resistant, and longer-lasting, providing improved fluid handling and lower replacement costs.

Choose composite screens if your operation prioritizes longevity and reduced maintenance.

3. Consider the Drilling Conditions

Different drilling environments require specific screen characteristics.

- High-temperature wells: Use heat-resistant materials.

- High-viscosity mud: Opt for screens with larger mesh openings.

- Fine solids drilling: Choose multi-layer fine mesh screens for better cuttings control.

4. Focus on Screen Compatibility

Always ensure that the shale shaker screen fits perfectly with your shale shaker brand and model (such as Mongoose, Derrick, Brandt, or FLC). Poorly fitted screens can lead to mud leakage, reduced efficiency, and equipment wear.

5. Balance Cost and Durability

High-quality shale shaker screens may cost more initially but provide longer service life and better performance. Investing in premium screens reduces downtime and overall operating expenses.

Conclusion

Choosing the right shale shaker screen for your operation requires balancing mesh size, screen type, drilling conditions, and cost efficiency. The correct selection ensures optimal solids control, better drilling fluid recovery, and longer equipment lifespan—making it a key factor in achieving sustainable, cost-effective drilling operations.

5 Common Shale Shaker Problems and How to Fix Them

Efficient solids control starts with a properly working shale shaker, the first line of defense in any drilling operation. However, even the best shale shakers can experience mechanical or operational issues that reduce performance. Understanding common shale shaker problems—and knowing how to fix them—helps ensure smooth drilling operations, optimal mud recovery, and reduced downtime.

1. Screen Blinding or Clogging

Problem: Drilling cuttings or sticky solids block the mesh openings, preventing proper fluid flow.

Solution:

Use appropriate shaker screen mesh sizes for the drilling fluid.

Clean or replace screens regularly.

Apply screen cleaners or pretensioned composite screens to minimize clogging.

2. Excessive Vibration or Imbalance

Problem: Uneven vibration leads to noise, screen damage, and poor solids separation.

Solution:

Check and tighten all bolts and fasteners.

Inspect the vibration motors for misalignment or worn bearings.

Ensure the shaker deck is level and balanced.

3. Mud Leakage Around Screens

Problem: Drilling mud escapes around the screen edges instead of passing through the mesh.

Solution:

Replace worn rubber sealing strips or gaskets.

Verify the screen tensioning device and tensioning assembly are properly adjusted.

Inspect deck surfaces for damage or corrosion.

4. Short Screen Life

Problem: Screens tear or wear out quickly, increasing maintenance costs.

Solution:

Use quality shaker screens made of stainless steel or composite materials.

Avoid overtightening the tensioning system.

Check for uneven deck vibration or improper installation.

5. Poor Solids Separation Efficiency

Problem: Too much solid material remains in the drilling fluid, reducing mud quality.

Solution:

Adjust the deck angle for better solids conveyance.

Check that screens are properly tensioned and aligned.

Maintain a consistent G-force for stable operation.

Conclusion

Most shale shaker problems can be avoided through regular inspection, proper maintenance, and the use of high-quality parts such as shaker screens, tensioning devices, and rubber strips. By addressing issues early, operators can improve solids control efficiency, extend equipment lifespan, and keep drilling operations running smoothly.

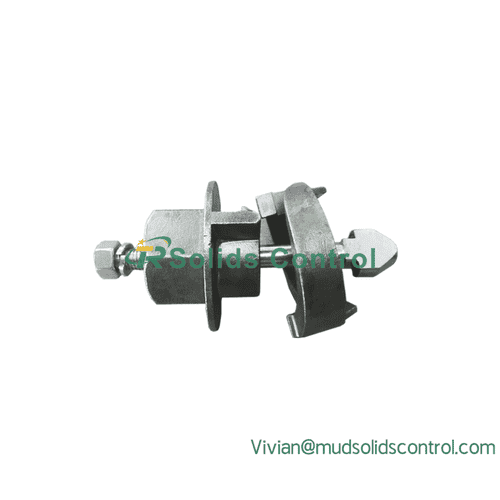

Shale Shaker Tensioning Assembly – Ensuring Secure Screen Installation for Efficient Solids Control

The shale shaker tensioning assembly is an essential component in drilling solids control equipment. Designed to firmly secure shaker screens to the shaker deck, the tensioning assembly ensures efficient separation of drill cuttings from drilling fluids. Without a reliable tensioning system, screens may loosen, causing fluid bypass, reduced solids removal efficiency, and unnecessary mud loss. By maintaining proper screen stability, the shale shaker tensioning assembly plays a key role in the overall performance of shale shakers.

Functions of a Shale Shaker Tensioning Assembly

Screen Stability – Keeps shaker screens firmly in position during vibration.

Efficient Solids Removal – Ensures all drilling fluids pass through the mesh for maximum filtration.

Leakage Prevention – Reduces the risk of drilling mud bypassing around the screens.

Extended Screen Life – Minimizes damage from uneven wear caused by loose fitting.

Benefits of High-Quality Tensioning Assemblies

Reliable Performance – Maintains consistent screen tension even under high G-force conditions.

Durability – Resistant to abrasion, vibration, and exposure to drilling fluids.

Easy Maintenance – Allows quick installation and replacement of screens.

Cost Efficiency – Reduces downtime and improves overall drilling productivity.

Conclusion

A shale shaker tensioning assembly may seem like a small component, but it is critical for reliable solids control operations. By keeping shaker screens secure, preventing mud loss, and improving separation efficiency, this assembly ensures better drilling performance and reduced operational costs. For long-lasting and stable performance, choosing a high-quality tensioning assembly is essential for any shale shaker system.

Shaker Screen Tensioning Device – Key Component for Reliable Shale Shaker Performance

A shaker screen tensioning device is one of the most important parts of a shale shaker, ensuring that screens are held firmly in place for efficient solids separation. Without proper screen tensioning, drilling fluids can bypass the screen mesh, leading to poor solids control, higher mud loss, and reduced shaker efficiency. By keeping screens tightly secured to the shaker deck, the shaker screen tensioning device plays a vital role in reliable drilling operations.

Functions of a Shaker Screen Tensioning Device

Firm Screen Positioning – Prevents screen movement or looseness during vibration.

Improved Separation Efficiency – Ensures drilling fluids pass through the screen for maximum solids removal.

Leakage Prevention – Reduces mud bypass and improves fluid recovery.

Extended Screen Life – Prevents excessive wear and damage caused by improper fitting.

Benefits of High-Quality Tensioning Devices

Consistent Performance – Maintains stable screen tension even in high-G force shale shakers.

Durable Construction – Resistant to vibration, abrasion, and drilling fluids.

Easy Installation & Replacement – Saves time during screen changes.

Lower Operational Costs – Reduces downtime and prevents unnecessary screen replacements.

Conclusion

The shaker screen tensioning device may seem like a small accessory, but its role in shale shaker performance is critical. By keeping screens secure, preventing leaks, and ensuring efficient solids control, it directly improves drilling fluid management and reduces operational costs. For reliable and long-lasting performance, investing in high-quality shaker screen tensioning devices is essential for any drilling project.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/

Shale Shaker Rubber Strip – Essential Sealing Part for Solids Control Equipment

The shale shaker rubber strip is a critical sealing component used in drilling solids control systems. Installed between the shaker deck and shaker screens, rubber strips ensure proper sealing, prevent drilling fluids from bypassing the screens, and protect equipment from excessive wear. By maintaining efficient screen performance, shale shaker rubber strips directly contribute to reliable solids control, reduced mud loss, and extended service life of shaker parts.

Functions of a Shale Shaker Rubber Strip

Sealing Protection – Prevents drilling mud leakage between the screen and frame.

Improved Screen Efficiency – Ensures all drilling fluids pass through the screens for proper solids removal.

Vibration Absorption – Reduces screen damage caused by continuous vibration.

Longer Equipment Life – Minimizes wear on shaker screens and deck components.

Benefits of High-Quality Rubber Strips

Durability in Harsh Conditions – Resistant to oil, heat, and chemical exposure.

Easy Replacement – Designed for quick installation and maintenance.

Cost Savings – Reduces drilling fluid loss and extends shaker screen lifespan.

Stable Performance – Maintains consistent sealing throughout drilling operations.

The shale shaker rubber strip is widely used in:

Oil & Gas drilling – Ensures reliable solids control in deep wells.

HDD (Horizontal Directional Drilling) – Improves mud recovery in trenchless projects.

Mining & Tunneling – Enhances slurry separation efficiency in heavy-duty environments.

Conclusion

A shale shaker rubber strip may seem like a small accessory, but it plays a big role in solids control performance. By ensuring a secure seal, reducing mud loss, and protecting shaker screens, it supports efficient drilling operations and cost savings. Choosing durable, high-quality rubber strips is essential for maximizing shale shaker efficiency and extending equipment life.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/

Beyond Oil & Gas: The Role of Shale Shakers in Geothermal and HDD Drilling

While the shale shaker is most commonly associated with oil and gas drilling, its role extends far beyond the energy sector. Today, shale shakers are equally vital in geothermal drilling and HDD (Horizontal Directional Drilling), where efficient solids control and drilling fluid recovery are essential for project success. By effectively separating cuttings from drilling fluids, shale shakers improve system performance, reduce environmental impact, and lower operational costs across multiple industries.

Shale Shakers in Geothermal Drilling

Geothermal wells often involve high-temperature and abrasive drilling conditions. A shale shaker helps maintain drilling mud quality by:

✔ Removing abrasive cuttings that can damage pumps and downhole tools.

✔ Supporting stable wellbore conditions for safer drilling.

✔ Extending the life of expensive drilling fluids in high-heat environments.

With the growing demand for renewable energy, geothermal operators rely on shale shakers to ensure efficient, safe, and cost-effective drilling.

Shale Shakers in HDD Drilling

HDD projects, such as pipeline crossings and underground utility installations, require precise fluid management. Shale shakers in HDD operations provide:

✔ Efficient cuttings separation to keep drilling fluids clean.

✔ Reduced fluid loss for significant cost savings.

✔ Environmental compliance by minimizing waste discharge.

✔ Reliable performance in both large-scale and small directional drilling projects.

By maintaining cleaner drilling fluids, HDD contractors achieve faster drilling rates and reduce downtime.

Why Shale Shakers Matter Beyond Oilfields

From geothermal energy projects to HDD installations, shale shakers deliver the same core benefits: efficient solids control, reduced equipment wear, and optimized fluid management. Their adaptability makes them indispensable in modern drilling applications where precision and sustainability are top priorities.

The role of shale shakers in geothermal and HDD drilling highlights their versatility beyond oil & gas. By investing in high-performance shale shaker systems, contractors can achieve greater efficiency, lower costs, and improved environmental outcomes across a wide range of drilling industries.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/

Mongoose Shale Shaker – High-Performance Solids Control Equipment

The Mongoose shale shaker is a widely recognized drilling solids control system designed to deliver high efficiency in separating drill cuttings from drilling fluids. Known for its reliability, advanced design, and durable shaker screens, the Mongoose shale shaker is used extensively in oil & gas drilling, HDD (Horizontal Directional Drilling), and mining operations. By optimizing solids control, it helps maintain drilling fluid quality, reduce operating costs, and extend the service life of downstream equipment.

Key Features of the Mongoose Shale Shaker

High G-force linear motion for maximum solids separation efficiency.

Advanced shaker screen technology for improved fluid recovery and reduced screen wear.

Adjustable deck angles to adapt to different drilling conditions.

User-friendly screen replacement system for minimal downtime.

Rugged design built to perform in harsh drilling environments.

Benefits in Drilling Operations

Improved Solids Control – Effectively removes cuttings, ensuring drilling fluids maintain their properties.

Reduced Operational Costs – Less mud loss and longer-lasting equipment mean better cost efficiency.

Environmental Compliance – Supports safer waste management by minimizing drilling fluid disposal.

Versatile Applications – Suitable for oilfield drilling, HDD projects, tunneling, and environmental remediation.

Why Choose the Mongoose Shale Shaker

The Mongoose shale shaker has become a preferred choice among drilling contractors due to its proven reliability, innovative screen design, and ability to handle demanding conditions. With its combination of high capacity and reduced maintenance needs, it ensures stable drilling performance across a wide range of applications.

In today’s competitive drilling industry, the Mongoose shale shaker stands out as a critical piece of solids control equipment. By investing in advanced shale shaker technology, drilling companies can achieve improved efficiency, lower costs, and better environmental compliance.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/h

Essential Shale Shaker Parts for Reliable Solids Control Operations

Reliable shale shaker parts are the backbone of efficient solids control operations in drilling projects. As the first stage of solids removal, shale shakers depend on high-quality components to separate drill cuttings from drilling fluids, reduce wear on downstream equipment, and optimize mud recovery. Understanding the role of each shale shaker part helps operators achieve consistent drilling performance and minimize costly downtime.

Key Shale Shaker Parts

Shaker Screens

Shaker screens are the most vital parts of a shale shaker. Built with durable stainless steel mesh, they filter solids while allowing clean drilling fluid to pass through. Selecting the right mesh size ensures precise solids control and maximum fluid recovery.

Shaker Screen Tensioning Device

This device secures shaker screens tightly to the deck, preventing leaks and ensuring stable performance. A reliable tensioning system allows quick screen changes and reduces downtime during drilling operations.

Shale Shaker Spring

Springs absorb vibration and isolate motion, protecting the shaker structure from excessive stress. High-quality shale shaker springs improve operational stability, reduce noise, and extend equipment life.

Shaker Screen Support

The screen support provides a solid foundation for screens under heavy loads. Strong supports maintain even distribution of vibration, preventing premature screen wear and ensuring efficient solids separation.

Screen Wedge

Screen wedges lock screens in place for secure operation. They simplify installation and replacement, helping crews maintain efficiency while keeping the shaker running safely and reliably.

Why High-Quality Parts Matter

Investing in durable shale shaker parts minimizes failures, reduces maintenance costs, and ensures compliance with drilling standards. Quality components not only improve solids control but also protect expensive downstream equipment such as desanders, desilters, and centrifuges.

Conclusion

From shaker screens and tensioning devices to springs, supports, and screen wedges, each shale shaker part plays a critical role in solids control operations. Using reliable components ensures efficient fluid management, longer equipment lifespan, and lower overall drilling costs—making these parts indispensable for any oilfield or HDD project.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/h

Top Benefits of Using Linear Motion Shale Shakers in Oilfield Drilling

In the demanding environment of oilfield drilling, achieving peak efficiency and cost-effectiveness is paramount. A critical component in this pursuit is the choice of solids control equipment, where Linear Motion Shale Shakers have become the industry standard for modern operations. Unlike older balanced elliptical motion shakers, linear models provide a more controlled and efficient method for primary solids removal. This article explores the key advantages of utilizing Linear Motion Shale Shakers and why they are a smart investment for enhancing overall drilling performance and protecting your bottom line.

1. Superior Solids Control and Dryer Cuttings

The defining feature of Linear Motion Shale Shakers is their straight-line, forward-moving vibration. This motion aggressively conveys solids uphill while allowing drilling fluid to pass through the screens efficiently. The result is remarkably superior solids control, with cuttings being discharged much drier than those from elliptical motion shakers. Dryer cuttings mean less valuable drilling fluid is wasted, leading to direct cost savings and reduced environmental footprint.

2. Enhanced Drilling Fluid Cleaning

The primary job of any shaker is to clean the drilling fluid by removing drilled solids. The efficient, non-diluting action of linear motion ensures that the fluid returned to the active system is significantly cleaner. This high level of drilling fluid cleaning protects downstream equipment like desanders and desilters from being overloaded, improves drilling rates, and enhances overall wellbore stability.

3. Increased Screen Life and Reduced Maintenance

The linear motion is smoother and more balanced than the aggressive circular motion of older shakers. This balanced action puts less stress on the screen panels, dramatically increasing their operational life. Longer screen life directly translates to reduced maintenance cost, as screens need to be replaced less frequently. This not only saves money on parts but also minimizes costly downtime for screen changes, directly boosting oilfield drilling efficiency.

4. Excellent Performance with High-Viscosity Fluids

Linear Motion Shale Shakers excel when handling a wide range of drilling fluids, especially higher-viscosity muds that can quickly blind screens on elliptical motion units. The powerful, straight-line motion helps to break the gel strength of the fluid, ensuring it passes through the screens effectively without plugging. This versatility is crucial for challenging drilling applications.

5. Improved Reliability and Operational Simplicity

With fewer moving parts subjected to extreme stress compared to older designs, linear motion shakers are known for their mechanical reliability. Their robust construction and simpler mechanics lead to fewer breakdowns and lower long-term operating costs, contributing to a safer and more predictable operation on the rig floor.

Conclusion: A Linear Path to Efficiency

Upgrading to Linear Motion Shale Shakers is a clear strategic move for any drilling operation focused on optimization. The combination of superior solids control, enhanced fluid cleaning, longer screen life, and overall reliability makes them an indispensable tool for maximizing oilfield drilling efficiency. By ensuring cleaner fluid and reducing operational costs, these shakers provide a rapid return on investment and set a new standard for performance in the field.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Call:+86-15339143604

WhatsApp:+86-15339143604

E-mail:Vivian@mudsolidscontrol.com

Web:https://www.trjxsb.com/h